Method for preparing 13X type molecular sieve through coal ash

A technology of fly ash and molecular sieve, which is applied in chemical instruments and methods, other chemical processes, and eight-sided crystalline aluminum silicate zeolite, etc., to achieve the effects of low cost, saving of chemical raw materials, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

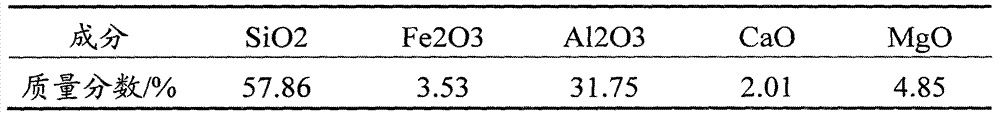

Method used

Image

Examples

Embodiment 1

[0018] Keeping the basicity and stirring speed constant, the effect of crystallization temperature on the synthesis of zeolite was investigated.

[0019] According to the research of the inventors, the adsorption amount increases obviously when the temperature is lower than 100°C, and the adsorption amount tends to decrease when the temperature exceeds 100°C. The chromium ion adsorption capacity of crystallized zeolite at 60°C is relatively large, but it takes about 18h; the crystallization time can be shortened to 10h at 85°C, but the chromium ion adsorption capacity is slightly reduced; when crystallized at 120°C, only It takes 4.5h, but the chromium ion adsorption capacity is significantly lower than the value at 100°C.

[0020] The crystallization temperature should not be too low, otherwise the crystallization process will be too slow, the purity of the synthetic stone will be low, and the adsorption effect will be poor; it should not be too high, because the X-type zeoli...

Embodiment 2

[0023] Keeping the synthesis temperature at 100°C and keeping factors such as alkalinity and stirring speed constant, the effect of crystallization time on the synthesis of zeolite was investigated.

[0024] According to the research of the inventors, when the crystallization time is short, the crystallinity of the synthesized sample is not high or presents an amorphous state. This is because the process of synthesizing zeolite by hydrothermal method is divided into two stages, namely the formation of crystal nuclei (induction period) and the growth of crystal nuclei. When the crystallization time is short, the synthesis process is only in the induction period, and the crystal nucleus stops before it grows up. The zeolite molecular sieve is a metastable crystal. If the crystallization time is too long, the synthetic sample will be destroyed under alkaline conditions, resulting in a decrease in crystallinity or crystal transformation to form other crystals. Therefore, the cryst...

Embodiment 3

[0026] Keeping the synthesis temperature at 100°C, crystallization time (8h), stirring speed and other factors unchanged, the influence of alkali concentration on the synthesis of zeolite was investigated.

[0027] The zeolite synthesized with NaOH with concentrations of 1.4832, 0.9488, and 0.9477mol / L was made into three samples a, b, and c. When synthesizing, SiO2 / Al2O3=3 (molar ratio), crystallization temperature 100°C, H2O / Na2O =55 (molar ratio), crystallization time 8h.

[0028] According to the research results, the three samples all have the diffraction peaks of faujasite, and the basicity n of sample a: 1.4832 (mol / L) is obviously greater than that of sample b: 0.9488 (mol / L), so when alkali is dissolved, Low concentration of NaOH cannot synthesize high-quality faujasite, and high concentration of NaOH can synthesize higher purity faujasite. Experiments have determined that the appropriate alkalinity is 1.4-1.5 mol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com