Method for preparing 4-substituted oxyphenol compound

An oxyphenol and compound technology, applied in the field of organic synthesis, can solve the problems of poor selectivity for synthesizing 4-substituted oxyphenol, difficult recovery of solvent and hydroquinone, complicated process, etc., and avoid side reactions and reaction steps. Short, highly selective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

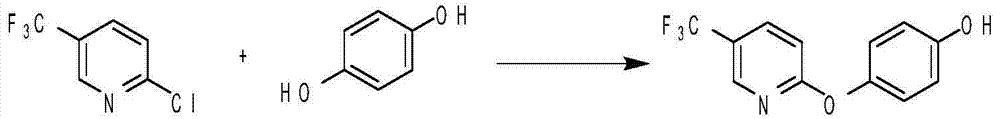

[0034] Example 1 Synthesis of 4-(5-trifluoromethylpyridyl-2-oxygen)phenol

[0035] The synthetic reaction formula is:

[0036]

[0037] The specific synthesis is as follows: add 6.0g of sodium hydroxide, 11.1g of hydroquinone, 8.0g of sodium bisulfite and 50g of DMF to the reaction bottle, then raise the temperature, and add dropwise 9.2g of 2-chloro-5-trifluoroform under temperature control at 90°C Basepyridine, add dropwise in about 1 hour, after dropping, keep warm at 90°C for 5 hours, after the conversion of raw materials is complete, distill and concentrate the reaction solution under reduced pressure, add 100ml of toluene after completion, stir for 1 hour, filter, and recover hydroquinone. Add 100ml of 5% sodium hydroxide aqueous solution to the toluene phase to extract twice, separate the water phase, add hydrochloric acid dropwise at a temperature of 25-30°C to acidify to pH 5-6, stir for 30 minutes, filter and dry to obtain 12.5g of 4-(5-tri Fluoromethylpyridyl-2-...

Embodiment 2

[0038] Example 2 Synthesis of 4-(5-trifluoromethylpyridyl-2-oxygen)phenol

[0039] After adding 86.8g of potassium hydroxide, 166.5g of hydroquinone, 88.5g of sodium bisulfite and 500g of DMF into the reaction flask, the temperature was raised, and 92g of 2-chloro-5-trifluoromethylpyridine was added dropwise at a temperature of 50°C, about 1 The dropwise addition was completed within 1 hour. After the dropwise completion, the reaction was carried out at 90°C for 5 hours. After the conversion of the raw materials was completed, the reaction solution was concentrated by distillation under reduced pressure. After the completion, 1000ml of toluene was added, stirred for 1 hour, filtered, and hydroquinone was recovered. Add 1000ml of 5% sodium hydroxide aqueous solution to the toluene phase to extract twice, separate the water phase, add hydrochloric acid dropwise at a temperature of 25-30°C to acidify to pH 5-6, stir for 30 minutes, filter and dry to obtain 128.8g of 4-(5-tri Fluo...

Embodiment 3

[0040] Example 3 Synthesis of 4-(5-trifluoromethylpyridyl-2-oxygen)phenol

[0041] The operation method is the same as in Example 1, and the solvent is replaced with DMSO to obtain a product content of 97.8% and a yield of 96.9%. Recover hydroquinone 5.3g, content 94.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com