A kind of preparation method of low molecular weight high epoxy value cardanol epoxy resin

A cardanol epoxy resin and cardanol technology, which is applied in the direction of organic chemistry and the like, can solve the problems of non-self-solidification at high temperature, poor stability and weather resistance, and achieve the effects of low viscosity and good toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

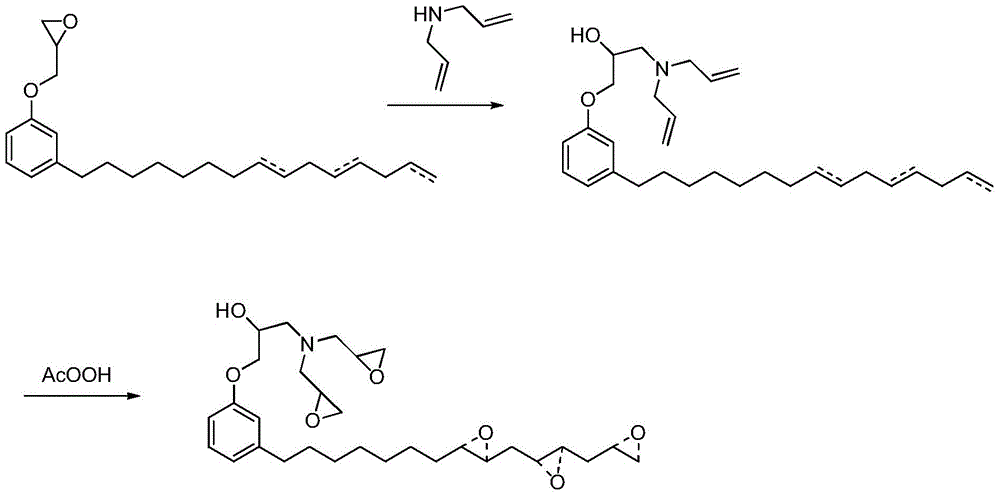

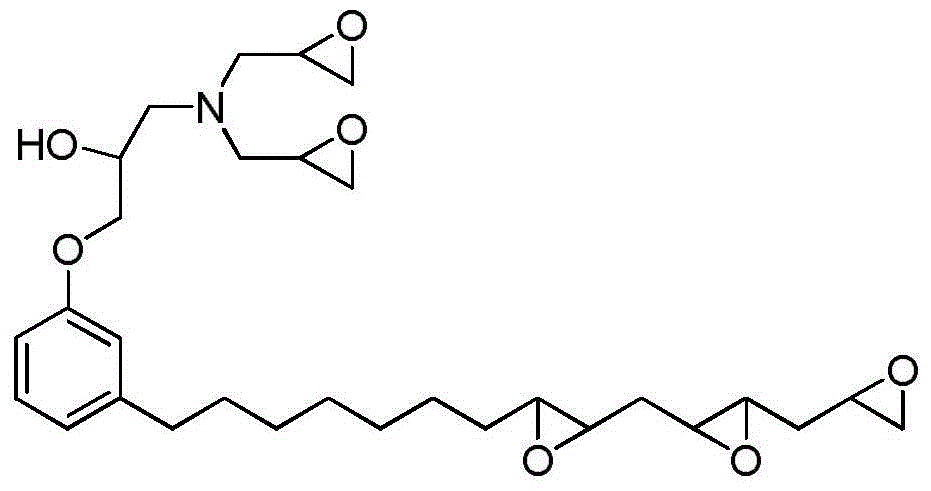

Method used

Image

Examples

Embodiment 1

[0021] Add 1 mole of cardanol monoglycidyl ether at room temperature, raise the temperature to 40 degrees, slowly add 1.2 moles of dipropylamine dropwise for 2 hours, control the temperature at 40-60 degrees, and add 1.5 peracetic acid after no obvious exothermic reaction Mole, 0.3% styrene peroxybenzoic acid is used as a catalyst, and the solvent is 100 mL of chloroform for oxidation, reacted at 50 degrees for 5 hours, washed with water to neutralize the acid and alkali, and filtered to remove the solvent to obtain the desired product.

[0022] The measured epoxy value is 0.38, the viscosity is 2500, the surface is dry in 28 minutes, the hard work is 5 hours, the toughness is 1mm, and the Shore hardness is 80 after self-curing at 160 degrees for 2 hours and cooling to room temperature.

Embodiment 2

[0024] Add 1 mole of cardanol monoglycidyl ether at room temperature, raise the temperature to 50 degrees, slowly add 1.1 moles of dipropylamine dropwise for 2 hours, control the temperature at 40-60 degrees, and add 1.5 peracetic acid after no obvious exothermic reaction Mole, 0.3% styrene peroxybenzoic acid is used as a catalyst, and the solvent is 100 mL of chloroform for oxidation, reacted at 50 degrees for 5 hours, washed with water to neutralize the acid and alkali, and filtered to remove the solvent to obtain the desired product.

[0025] The measured epoxy value is 0.38, the viscosity is 2600, the surface is dry for 32 minutes, hard drying for 5 hours, the toughness is 1mm, and the Shore hardness is 78 after self-curing at 160 degrees for 2 hours and cooling to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com