Preparation method and application of hindered phenolic quaternary phosphonium salt modified montmorillonite synergistic halogen-free expansion flame retardant

A hindered phenolic quaternary phosphonium salt and intumescent flame retardant technology, applied in the field of material science, can solve the problems of high flame retardant cost, large amount of IFR addition, poor compatibility, etc., and achieve good processing stability, excellent flame retardant effect, long lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Synthesis of benzyl chloride hindered phenol: under the protection of N2, add 10 parts of 2,6 di-tert-butylphenol (Zibo Shibang Chemical Co., Ltd. ), 20 parts of paraformaldehyde, 5 parts of n-heptane, 0.01 part of initiator, the temperature was raised to 70°C, and the 2,6 phenol was completely dissolved under magnetic stirring. Add 3 parts of concentrated hydrochloric acid dropwise to the above solution, continue the constant temperature reaction at 70°C for 12 hours, then cool the reaction solution to room temperature, separate the liquids, extract the water phase with 20 parts of ethyl acetate and mix it with the organic layer, and wash the organic layer with deionized water until neutral. properties, washed with saturated brine, dried over anhydrous Na2SO4, recovered solvent by distillation under reduced pressure, and dried under vacuum at 30°C for 12h to obtain hindered phenol containing benzyl chloride.

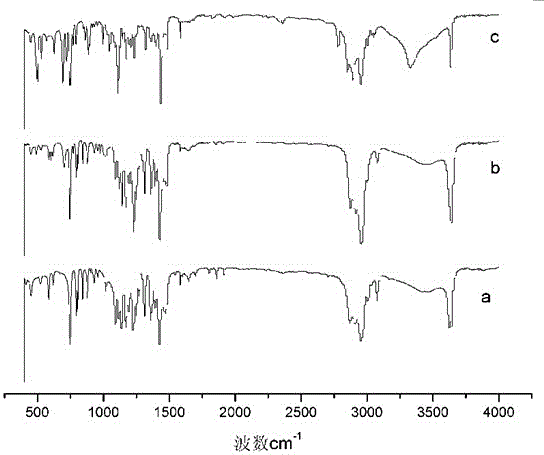

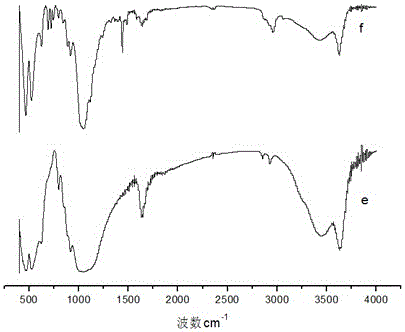

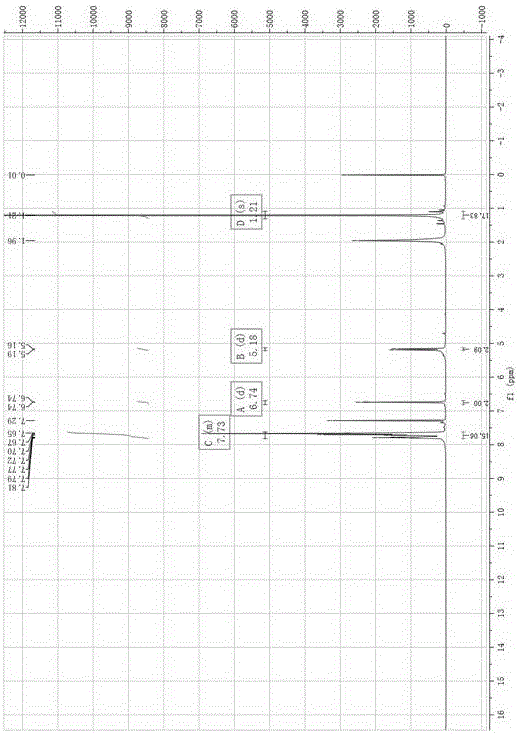

[0027] FT-IR of the synthesized benzyl hindered phenol ...

Embodiment 2

[0036] The difference between this implementation and Example 1 is that the reaction temperature in step (1) is changed to 80°C, the reaction time is 18h, 17.5 parts of n-heptane, 0.3 parts of initiator, 50 parts of paraformaldehyde, 0.5 parts of hydrochloric acid, 50 parts of ethyl acetate. In step (2), the temperature is 50°C, the reaction time is 3 hours, 12 parts of organic phosphine, 10 parts of n-heptane as solvent, and 50 parts of petroleum ether. In step (3), the temperature of the water bath is 70° C., the reaction time is 24 hours, the volume of deionized water is 500 mL, and the volume of hindered phenolic quaternary phosphonium salt is 4.5 parts. In step (4), the amount of hindered phenolic quaternary phosphonium salt modified montmorillonite synergistic halogen-free expansion flame retardant is 22 parts of flame retardant (including 3 parts of hindered phenolic quaternary phosphonium salt modified montmorillonite, polymer 14 parts of amine phosphate, 2 parts of p...

Embodiment 3

[0039] The difference between this implementation and Example 1 is that the reaction temperature in step (1) is changed to 90°C, the reaction time is 24h, 25 parts of n-heptane, 0.1 part of initiator, 100 parts of paraformaldehyde, 1.5 parts of hydrochloric acid, ethyl acetate 30 parts of ester. In step (2), the temperature is 60° C., the reaction time is 4 hours, 10 parts of di-n-heptane as solvent, 30 parts of petroleum ether, and 11 parts of organic phosphine. In step (3), the temperature of the water bath is 80° C., the reaction time is 12 hours, 450 mL of deionized water, and 5.5 parts of hindered phenolic quaternary phosphonium salts. In step (4), the amount of hindered phenolic quaternary phosphonium salt modified montmorillonite synergistic halogen-free expansion flame retardant is 26 parts of flame retardant (including 3 parts of hindered phenolic quaternary phosphonium salt modified montmorillonite, 18 parts of amine polyphosphate, 2 parts of pentaerythritol, 3 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com