Impregnated resin, impregnated film adhesive, manufacturing methods of impregnated resin and impregnated film adhesive, and laminated floor

A technology of impregnating adhesive film paper and impregnating resin, which is applied to laminate flooring materials, impregnating melamine resin for laminate flooring impregnating paper and its manufacture, impregnating adhesive film paper and its manufacturing field, which can solve the problem of difficult to manufacture, low formaldehyde Issues such as release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0132] The impregnation resin used to produce impregnated film paper, its components include melamine-formaldehyde resin, urethane phthalic acid, formaldehyde scavenger, and the preparation process includes the following processes:

[0133] 1) Preparation of melamine formaldehyde resin

[0134] Add 810 parts by weight of 37wt% formaldehyde and 330 parts by weight of water into the reaction kettle, start the agitator, and adjust the pH value to 9-9.5 with sodium hydroxide;

[0135] Add 700 parts by weight of melamine, raise the temperature to 80-82°C, and keep the pH value at 9-9.5;

[0136] Raise the temperature to 95-97°C, keep it warm for 10-15 minutes, and keep the pH value at 9-9.5;

[0137] Keep warm at 95°C until the glue sample appears turbid in 20°C water, measure the viscosity with Tu-4 cup to be 14-14.5S, and the pH value is above 9;

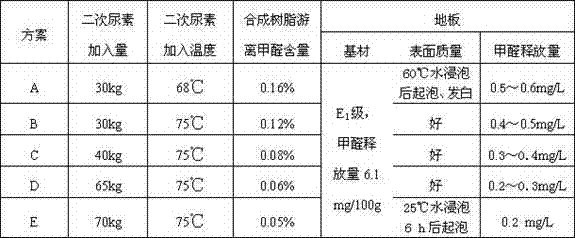

[0138] Cool down to 82-85°C, add 30 parts by weight of urea, keep warm until coated with 4 cups and measure the viscosity at 14.5-1...

Embodiment 2

[0155] The impregnation resin used to produce impregnated film paper, its components include melamine-formaldehyde resin, urethane phthalic acid, formaldehyde scavenger, and the preparation process includes the following processes:

[0156] 1) Preparation of melamine formaldehyde resin

[0157] Add 830 parts by weight of 37wt% formaldehyde and 340 parts by weight of water into the reaction kettle, start the agitator, and adjust the pH value to 9-9.5 with sodium hydroxide;

[0158] Add 700 parts by weight of melamine, raise the temperature to 80-82°C, and keep the pH value at 9-9.5;

[0159] Raise the temperature to 95-97°C, keep it warm for 10-15 minutes, and keep the pH value at 9-9.5;

[0160] Keep warm at 95°C until the glue sample appears turbid in 20°C water, measure the viscosity with Tu-4 cup to be 14-14.5S, and the pH value is above 9;

[0161] Cool down to 82-85°C, add 35 parts by weight of urea, keep warm until coated with 4 cups and measure viscosity to 14.5-15S; ...

Embodiment 3

[0178] The impregnation resin used to produce impregnated film paper, its components include melamine-formaldehyde resin, urethane phthalic acid, formaldehyde scavenger, and the preparation process includes the following processes:

[0179] 1) Preparation of melamine formaldehyde resin

[0180] Add 860 parts by weight of 37wt% formaldehyde and 350 parts by weight of water into the reaction kettle, start the agitator, and adjust the pH value to 9-9.5 with sodium hydroxide;

[0181] Add 700 parts by weight of melamine, raise the temperature to 80-82°C, and keep the pH value at 9-9.5;

[0182] Raise the temperature to 95-97°C, keep it warm for 10-15 minutes, and keep the pH value at 9-9.5;

[0183] Keep warm at 95°C until the glue sample appears turbid in 20°C water, measure the viscosity with Tu-4 cup to be 14-14.5S, and the pH value is above 9;

[0184] Cool down to 82-85°C, add 40 parts by weight of urea, keep warm until the viscosity is 14.5-15 S when coated with 4 cups;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com