Chemical tinning liquid, preparation method thereof and chemical tinning method

A technology of chemical tin plating and tin salt, applied in the field of chemical plating, can solve problems such as poor stability of chemical tin plating solution, achieve high compactness, ensure long-term stability, and solve the effects of poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides the preparation method of described electroless tin-plating liquid, comprises first tin salt, complexing agent, reducing agent are dissolved in water respectively to prepare respective aqueous solution, then tin salt solution and complexing agent aqueous solution are first mixed, and then Adding a sulfonic acid accelerator, and finally mixing with an aqueous solution of a reducing agent, obtains the electroless tin plating solution.

[0032] As mentioned above, the electroless tin plating solution needs to be guaranteed to be in an alkaline environment, so a pH regulator needs to be added to adjust the pH value of the system. Preferably, after the components in the electroless tin plating solution are uniformly mixed, a pH regulator can be added to adjust the pH value of the system to 8-10, and the chemical tin plating solution provided by the present invention can be obtained.

[0033]Finally, the present invention provides an electr...

Embodiment 1

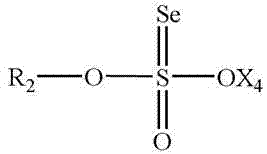

[0036] Dissolve tin salt, complexing agent, reducing agent titanium chloride, surfactant PEG1000, and thiourea in water to prepare their respective aqueous solutions according to the formula, then mix the tin salt solution and complexing agent aqueous solution first, and then add sulfonic acids Accelerator, after stirring for 2min, add other aqueous solutions, finally add 25wt% ammonia water to adjust the pH value of the system, and obtain the electroless tin plating solution S1 of the present embodiment. Its formula is: stannous sulfate 10g / L, sodium citrate 30g / L, Methanesulfonic acid 20g / L, sulfamic acid 10g / L, potassium dodecyl selenosulfonate 3g / L, PEG1000 0.05g / L, thiourea 6g / L, titanium chloride 4g / L, ammonia water 7g / L L, pH 9.0.

Embodiment 2

[0038] Adopt the method identical with embodiment 1 to prepare the electroless tin plating solution S2 of the present embodiment, its formula is: tin protochloride 12g / L, citric acid 40g / L, sodium methanesulfonate 30g / L, sulfamic acid 12g / L, potassium dodecyl selenosulfonate 4g / L, PEG1000 0.08g / L, thiourea 7g / L, titanium chloride 5g / L, ammonia water 9g / L, and the pH value is 9.6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com