Mimic enzyme, preparation method, application method and application of mimic enzyme

A technology for simulating enzymes and oxidases, which is applied in the field of nanotechnology and enzyme catalysis, which can solve the problems of cumbersome synthesis steps, low catalytic activity, and easy-to-use nanoparticles, and achieve excellent water solubility, high catalytic activity, and maintain catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

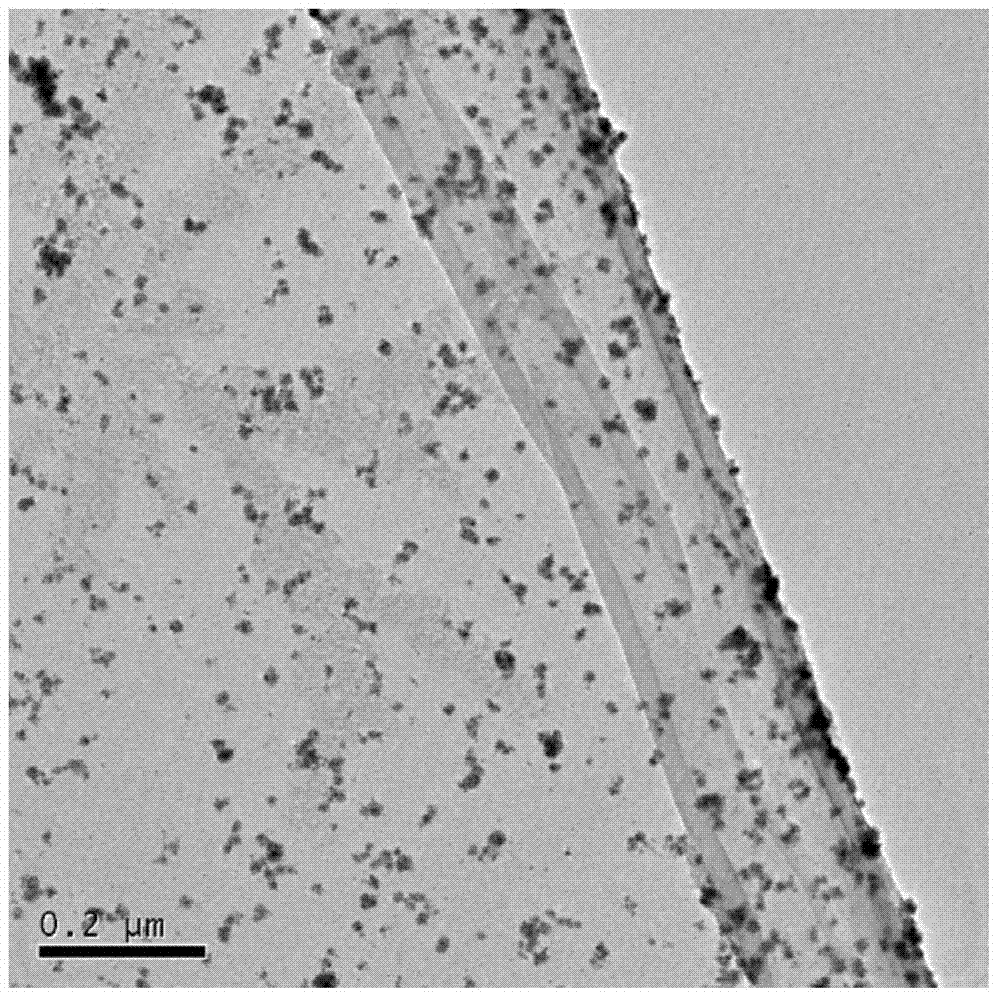

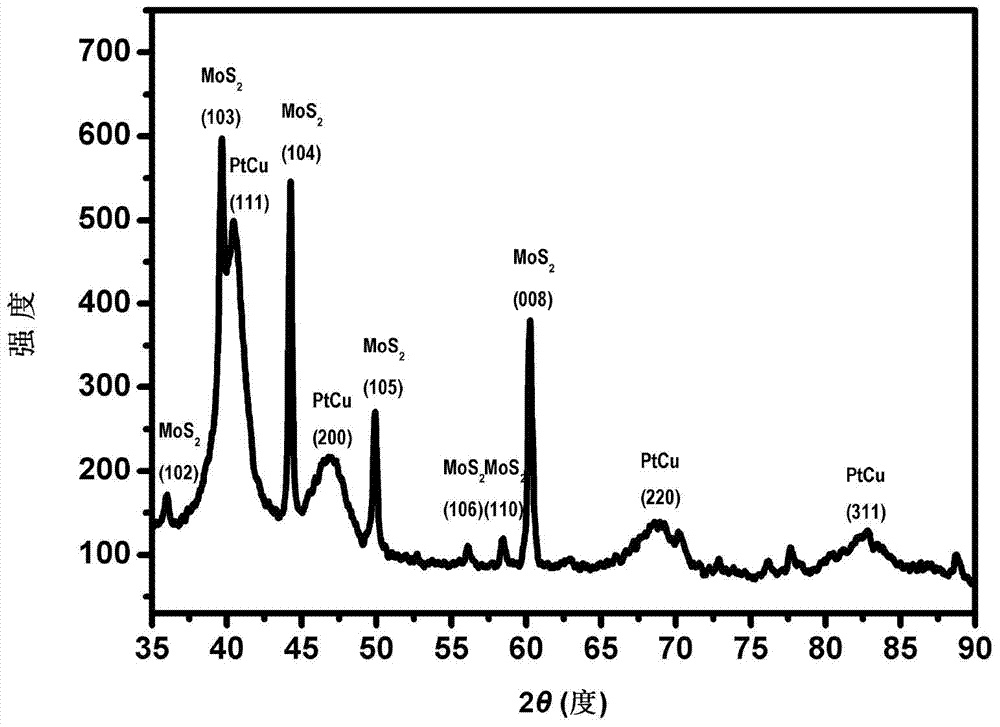

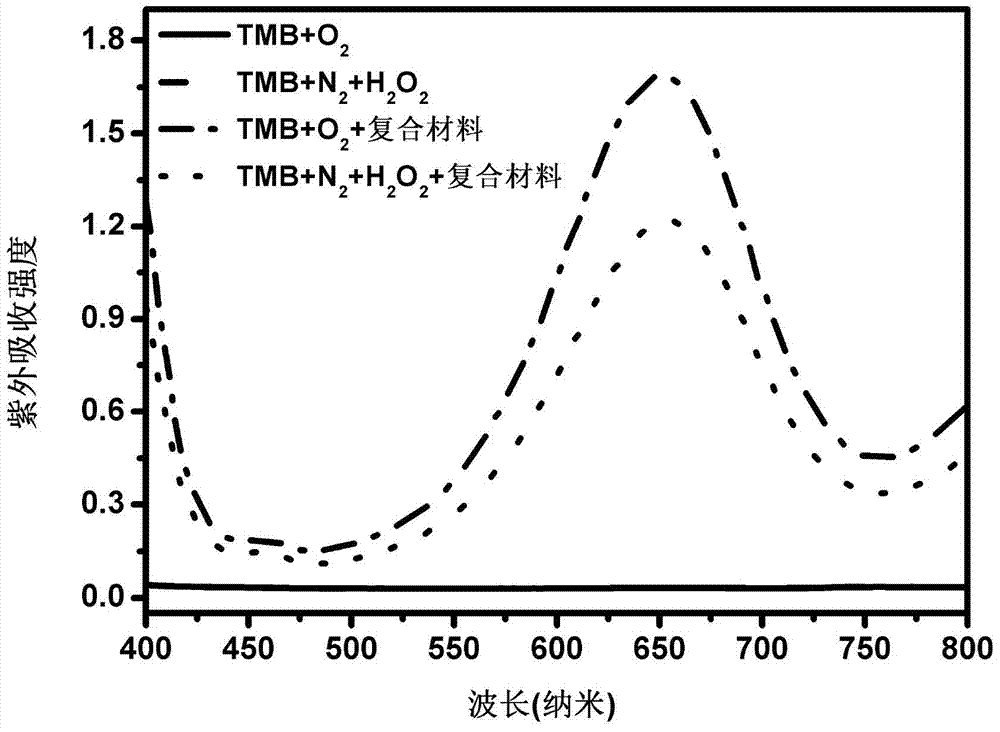

[0058] A mimetic enzyme based on a single-layer molybdenum disulfide-loaded platinum-copper alloy nanocomposite, obtained by the following method:

[0059] (1) Disperse the powdery molybdenum disulfide in the aqueous solution, and add 0.05wt% chitosan, and ultrasonically peel off to obtain the single-layer molybdenum disulfide aqueous solution modified by chitosan; the above-mentioned single-layer molybdenum disulfide, platinum chloride Disperse acid and copper acetate in 10mL of water to make the concentrations 2.4mg / L, 0.1mmol / L and 0.03mmol / L respectively, stir evenly, and place in an ice bath to cool for 20min to obtain molybdenum disulfide flakes, platinum Aqueous solutions of salts and copper salts;

[0060] (2) Add 1 mL of 9mmol / L sodium borohydride solution dropwise to the aqueous solution obtained in step (1) that is dispersed with molybdenum disulfide sheets, platinum salts and copper salts, the rate of addition is 60 μL / min, stir and continue to place Carry out red...

Embodiment 2

[0086] A mimetic enzyme based on a single-layer molybdenum disulfide-loaded platinum-copper alloy nanocomposite, obtained by the following method:

[0087] (1) Disperse powdered molybdenum disulfide in aqueous solution, and ultrasonically peel off to obtain a single-layer molybdenum disulfide aqueous solution; disperse single-layer molybdenum disulfide, chloroplatinic acid and copper chloride in 10mL water to make the concentrations 5mg respectively / L, 0.1mmol / L and 0.1mmol / L, stir evenly, place in an ice bath to cool for 20 minutes, and obtain an aqueous solution dispersed with molybdenum disulfide sheets, platinum salts and copper salts;

[0088] (2) Add 1mL of 12mmol / L sodium borohydride solution dropwise to the aqueous solution obtained in step (1) that is dispersed with molybdenum disulfide sheets, platinum salts and copper salts, the rate of addition is 30 μL / min, stir and continue to place Carry out reduction reaction in ice bath for 1h;

[0089] (3) After the reactio...

Embodiment 3

[0091] A mimetic enzyme based on a single-layer molybdenum disulfide-loaded platinum-copper alloy nanocomposite, obtained by the following method:

[0092] (1) Disperse powdered molybdenum disulfide in aqueous solution, and ultrasonically peel off to obtain a single-layer molybdenum disulfide aqueous solution; disperse single-layer molybdenum disulfide, chloroplatinic acid and copper acetate in 10mL water to make the concentrations respectively 4.5mg / L, 0.05mmol / L and 0.15mmol / L, stir evenly, place in an ice bath to cool for 15min, and obtain an aqueous solution dispersed with molybdenum disulfide sheets, platinum salts and copper salts;

[0093] (2) Add 10mmol / L sodium borohydride solution 1mL dropwise to the aqueous solution obtained in step (1) that is dispersed with molybdenum disulfide sheets, platinum salts and copper salts, the rate of addition is 50 μL / min, stir and continue to place Carry out reduction reaction in ice bath for 1h;

[0094] (3) After the reaction is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com