Mn4CaO4 core structure-containing water cracking catalyst and preparation method and application thereof

A heteronuclear, compound technology, applied in the field of biomimetic water splitting catalysts, can solve problems such as successful case reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

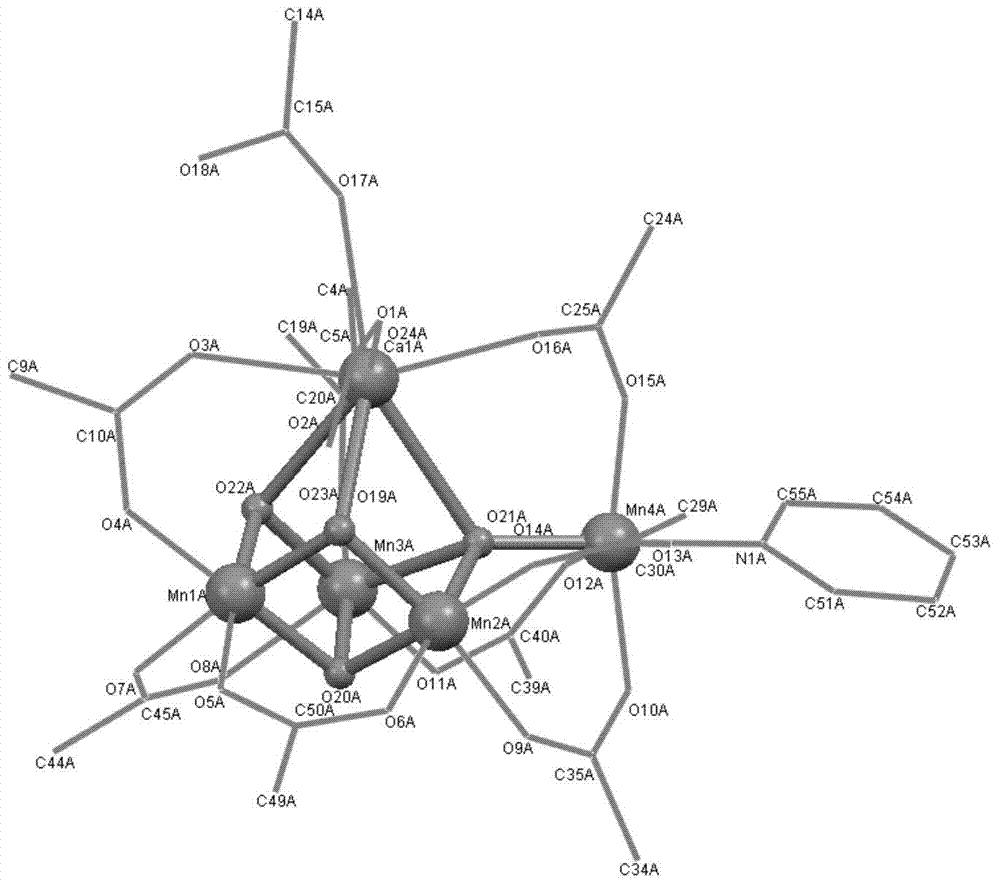

[0070] Embodiment 1: compound 1 [Mn 4 CaO 4 ](C 5 h 9 o 2 ) 8 (C 5 h 9 o 2 h) 2 (C 5 h 5 N)

[0071] The preparation method is as follows:

[0072] The first step is the synthesis of compound 1 precursor: in the round bottom flask of 100ml, add tetrabutylamine permanganate (Bu n 4 NMnO 4 , 4mmol), manganese acetate (Mn(CH 3 CO 2 ) 2 , 1mmol), calcium acetate (Ca(CH 3 CO 2 ) 2 , 1mmol) and pivalic acid ((CH 3 ) 3 CCO 2 H, 40mmol) was continuously reacted in acetonitrile at 80°C for 25min, then stopped the reaction, filtered to remove a small amount of precipitate, and the obtained brown mother liquor was placed at 0°C for 1-2 weeks, and brown crystals were precipitated.

[0073] The second step is recrystallization. The crystals obtained in the first step were collected, dissolved in ethyl acetate, recrystallized by adding 2% pyridine (volume ratio), and brown crystals were precipitated after 1 to 2 weeks, rinsed with cyclohexane, dried in vacuo, and the...

Embodiment 2

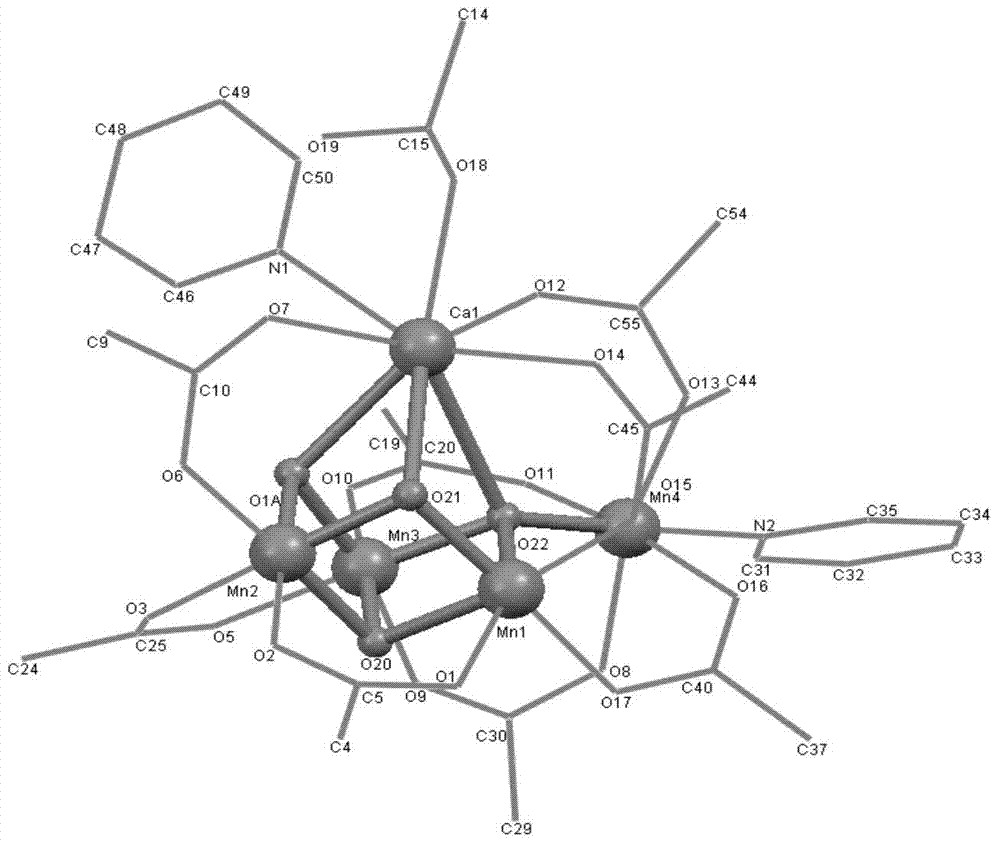

[0080] Embodiment 2: compound 2 [Mn 4 CaO 4 ](C 5 h 9 o 2 ) 8 (C 5 h 9 o 2 h) 1 (C 5 h 5 N) 2

[0081] Weigh 0.100 g of compound 1, dissolve it in ethyl acetate, add 1% pyridine, place at room temperature, and after 3 weeks, black crystals are precipitated, rinsed with cyclohexane, dried in vacuo, and the yield is ~ 13% (according to the concentration of Ca ions moles).

[0082] Compound 2, structural formula [Mn 4 CaO 4 (R 1 CO 2 ) 8 ](L 1 )(L 2 )(L 3 ), where R 1 = tert-butyl; L 1 =L 2 = pyridine; L 3 = pivalic acid.

[0083] That is, the structural formula of compound 2 is [Mn 4 CaO 4 ](C 5 h 9 o 2 ) 8 (C 5 h 9 o 2 h) 1 (C 5 h 5 N) 2 . Molecular formula: C 55 h 92 N 2 o 22 CaMn 4 . Elemental analysis theoretical value: C, 47.42; H, 6.66; N, 2.01; experimental value: C, 47.74; H, 6.89; N, 1.69.

[0084] The single crystal of compound 2 is monoclinic, and the space group is P2 1 / c1, the cell parameters are α=90.00°, β=102.70...

Embodiment 3

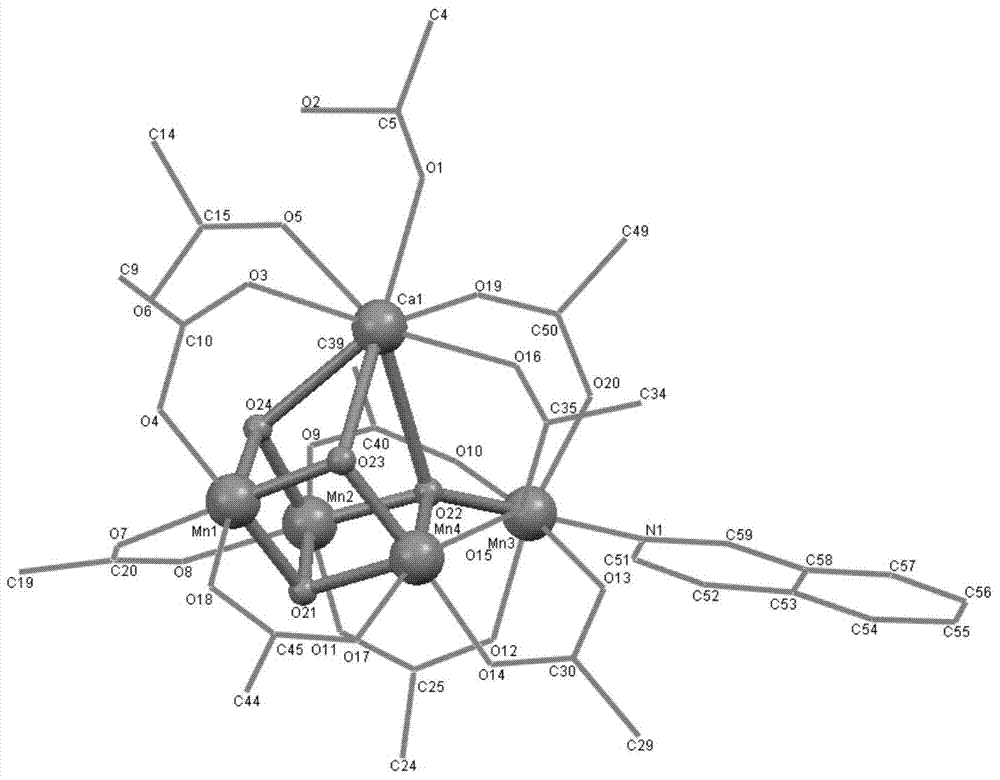

[0088] Embodiment 3: compound 3 [Mn 4 CaO 4 ](C 5 h 9 o 2 ) 9 (C 5 h 9 o 2 h) 2 (C 9 h 7 N)

[0089] The first step is the synthesis of compound precursor: in the round bottom flask of 100ml, add tetrabutylammonate permanganate (Bu n 4 NMnO 4 , 4mmol), manganese acetate (Mn(CH 3 CO 2 ) 2 , 1mmol), calcium acetate (Ca(CH 3 CO 2 ) 2 , 1mmol) and pivalic acid ((CH 3 ) 3 CCO 2 H, 40mmol) continued to react in acetonitrile at 80°C for 25min, then stopped the reaction, filtered to remove a small amount of precipitate, obtained brown mother liquor was placed at 0°C for 1-2 weeks, and brown crystals were precipitated.

[0090]The second step is recrystallization: collect the crystals obtained in the first step, dissolve them with ethyl acetate, add 1% isoquinoline (volume ratio) for recrystallization, collect black crystals after 1 to 2 weeks, and rinse with cyclohexane , dried in vacuo with ~40% yield (based on moles of Ca ions).

[0091] Compound 3, the struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| process yield | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com