Hydrazide pH sensitive polymer as well as preparation method and application thereof

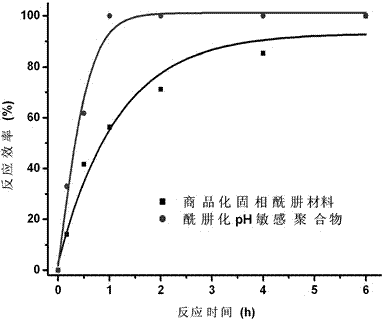

A polymer and sensitive technology, applied in the field of analytical chemistry, can solve the problems of reducing the enrichment efficiency of glycoprotein or glycopeptide, and reduce the reaction rate of aldehyde group, so as to achieve the effect of improving the reaction rate and the enrichment efficiency of glycopeptide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

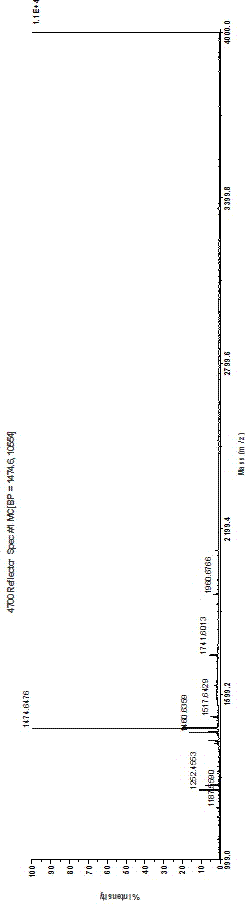

Examples

Embodiment 1

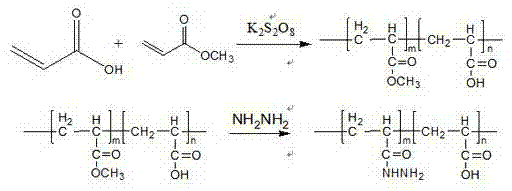

[0028] In the embodiment of the present invention, a hydrazide pH sensitive polymer, its raw material includes acrylic acid, methyl acrylate, potassium persulfate, hydrazine hydrate, methanol and water, the molar ratio of the acrylic acid and methyl acrylate is 1 :2, the molar ratio of the hydrazine hydrate and methyl acrylate is 1:10, the charging amount of the potassium persulfate is 0.02%w / v, and the volume ratio of the methanol and the aqueous phase is 1:3.

[0029] The preparation method of the hydrazide pH-sensitive polymer, the specific steps are as follows:

[0030] (1) Taking materials: Weigh each raw material according to the use standard;

[0031] (2) Free radical polymerization of acrylic acid and methyl acrylate: Mix methanol and water to obtain a mixed solution, fill the mixed solution with nitrogen to remove oxygen for 1.8 hours, add acrylic acid, methyl acrylate and potassium persulfate to the above In the oxygen removal solution, continue to remove oxygen for...

Embodiment 2

[0034] A kind of hydrazide pH sensitive polymer, its raw material comprises acrylic acid, methyl acrylate, ammonium persulfate, hydrazine hydrate, acetonitrile and water, and the molar ratio of described acrylic acid and methyl acrylate is 8:1, and described hydration The molar ratio of hydrazine and methyl acrylate is 5:1, the feeding amount of ammonium persulfate is 0.2% w / v, and the volume ratio of acetonitrile and water phase is 1:1.

[0035] The preparation method of the hydrazide pH-sensitive polymer, the specific steps are as follows:

[0036] (1) Taking materials: Weigh each raw material according to the use standard;

[0037] (2) Free radical polymerization of acrylic acid and methyl acrylate: mix acetonitrile and water to obtain a mixed solution, fill the mixed solution with argon to remove oxygen for 2 hours, add acrylic acid, methyl acrylate and ammonium persulfate to the above In the oxygen removal solution, continue to remove oxygen for 30 minutes, then remove t...

Embodiment 3

[0040] A kind of hydrazide pH sensitive polymer, its raw material comprises acrylic acid, methyl acrylate, azobisisobutyronitrile, hydrazine hydrate, ethanol and water, and the molar ratio of described acrylic acid and methyl acrylate is 10:1, The molar ratio of hydrazine hydrate and methyl acrylate is 8:1, the feeding amount of azobisisobutyronitrile is 1% w / v, and the volume ratio of ethanol and water phase is 1:5.

[0041] The preparation method of the hydrazide pH-sensitive polymer, the specific steps are as follows:

[0042] (1) Taking materials: Weigh each raw material according to the use standard;

[0043] (2) Free radical polymerization of acrylic acid and methyl acrylate: mix ethanol and water to obtain a mixed solution, and fill the mixed solution with nitrogen to remove oxygen for 2.2 hours, and acrylic acid, methyl acrylate and azobisisobutyronitrile Add to the above oxygen removal solution, continue to remove oxygen for 35 minutes, remove nitrogen protection, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com