Preparation method of reinforced mesh of glass grinding wheel for gasket

A technology for reinforcing mesh and glass, applied in glass manufacturing equipment, manufacturing tools, lighting and heating equipment, etc., can solve the problems of occupying space cost, affecting flatness, high cost, etc., and achieve reduced gasket cost, good hardness and flatness , The effect of uniform temperature inside and outside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Raw materials: glass mixed raw materials are mixed uniformly according to the following proportions, and the weight percentages of the components are as follows: SiO 2 53.5-54.5, Al 2 o 3 13.4-14.2, CaO 18.3-19, MgO 4-4.8, B 2 o 3 6.4-7.4, K 2 O 0.8-1, Na 2 O 0.8-1.2 、ZrO 2 2-5;

[0032] (2) Melting: completed in the alkali-free pool kiln;

[0033] (3) Wire drawing: use a wire drawing machine to draw and form, and perform infiltration treatment;

[0034] (4) Unwinding and spinning: the glass fiber pulled out by the wire drawing machine is first wound on the winding wire, through unwinding, plying, warping, weaving, and then coating, weft alignment, slicing, drying, and finally resin curing molding;

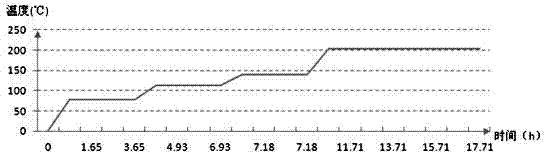

[0035] (5) The drying has four stages, such as figure 1 Shown:

[0036] The four stages of drying are as follows, the temperature of each stage is evenly increased, and the temperature is increased by 5°C every 30 seconds:

[0037] The first stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com