Positive electrode material and aqueous battery containing positive electrode material

A cathode material and battery technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of graphite corrosion of battery cathode conductive agent, reduction of battery cycle life, and gas generation of batteries, so as to avoid graphite corrosion and reduce battery production. Gas and self-discharge, the effect of suppressing performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

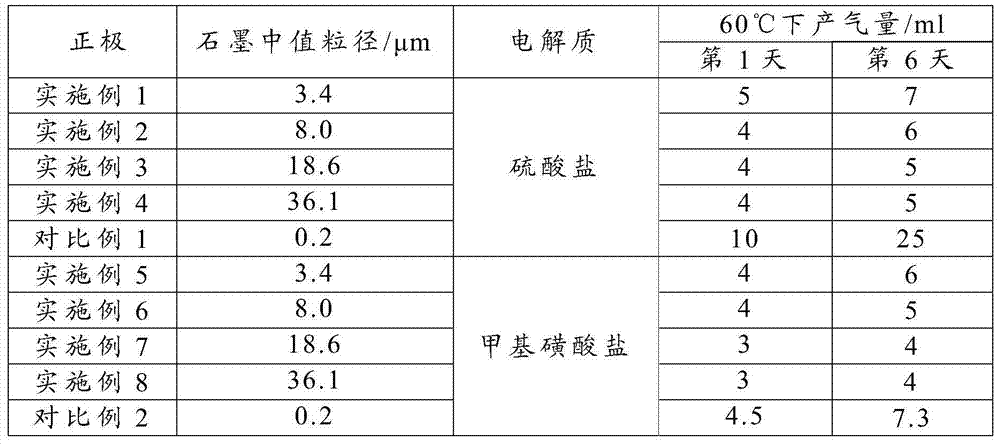

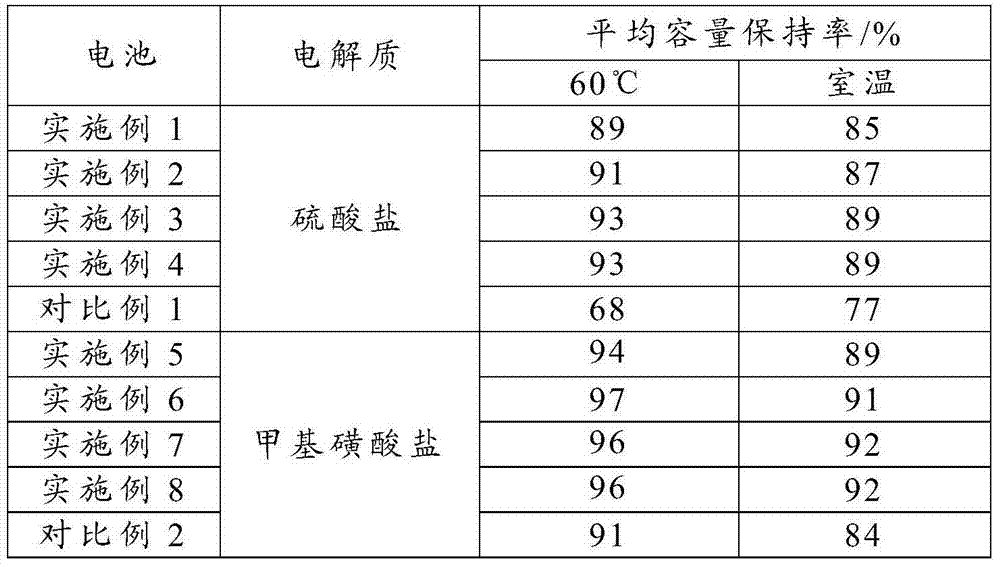

Embodiment 1

[0109] Mix lithium manganate LMO, conductive agent graphite, binder styrene-butadiene rubber (SBR) and sodium carboxymethyl cellulose (CMC) in water according to the mass ratio LMO:CMC:SBR:graphite=86.5:1:2.5:10 , forming a uniform positive electrode slurry. Graphite is spherical graphite, and the median diameter d50 of graphite is 3.4 μm, and d10 is 2 μm. The positive electrode slurry is coated on both sides of the positive electrode current collector to form an active material layer. The positive electrode current collector is carbon steel coated with a PE conductive film with a thickness of 200 μm. into the positive pole.

[0110] A zinc foil with a thickness of 50 μm was used as the negative electrode. The diaphragm is an AGM glass fiber diaphragm. The separator and negative electrode are comparable in size to the positive electrode. The positive electrode, the negative electrode and the diaphragm are laminated and assembled into a battery cell, which is loaded into th...

Embodiment 2

[0112] The difference from Example 1 is that the median particle diameter d50 of the conductive agent graphite is 8.0 μm, and the d10 is 3 μm, and the composition and materials of the other positive electrodes are the same as those in Example 1 to make the positive electrode.

Embodiment 3

[0114] The difference from Example 1 is that the median particle diameter d50 of the conductive agent graphite is 18.6 μm, and the d10 is 5 μm, and other positive electrode compositions and materials are the same as in Example 1 to make a positive electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com