Method and device for supplying hydrogen-selenide mixed gas

A technology of mixed gas and gas supply, applied in binary selenium/tellurium compounds, measuring devices, testing/calibrating devices, etc., can solve problems such as offset phenomenon, large difference between measured concentration values, offset and other problems, and reduce flow rate Measurement error and flow control error, reducing the precipitation of selenium crystals, and suppressing the effect of offset phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

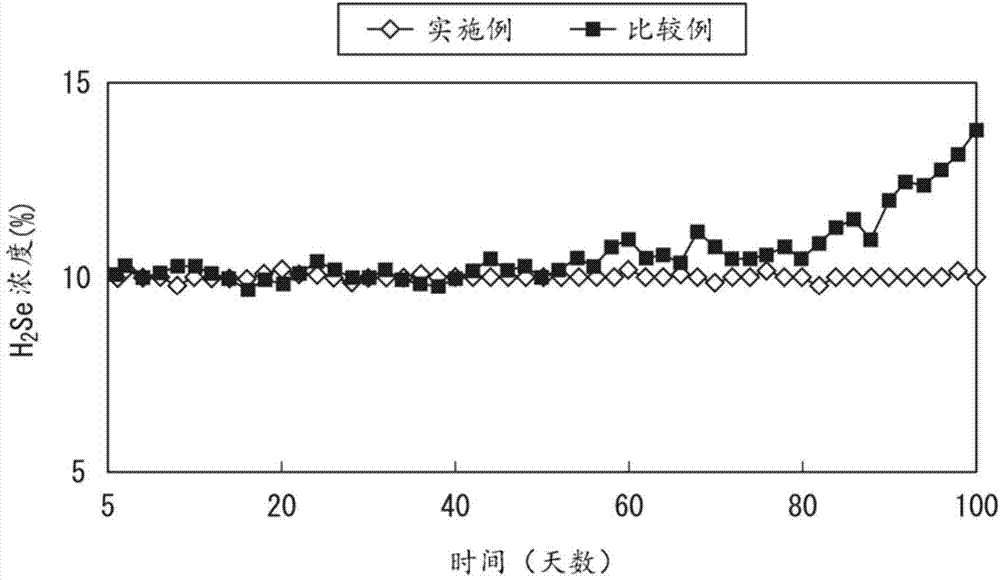

[0168] Preferred specific examples of the present invention are shown below.

[0169] (Example)

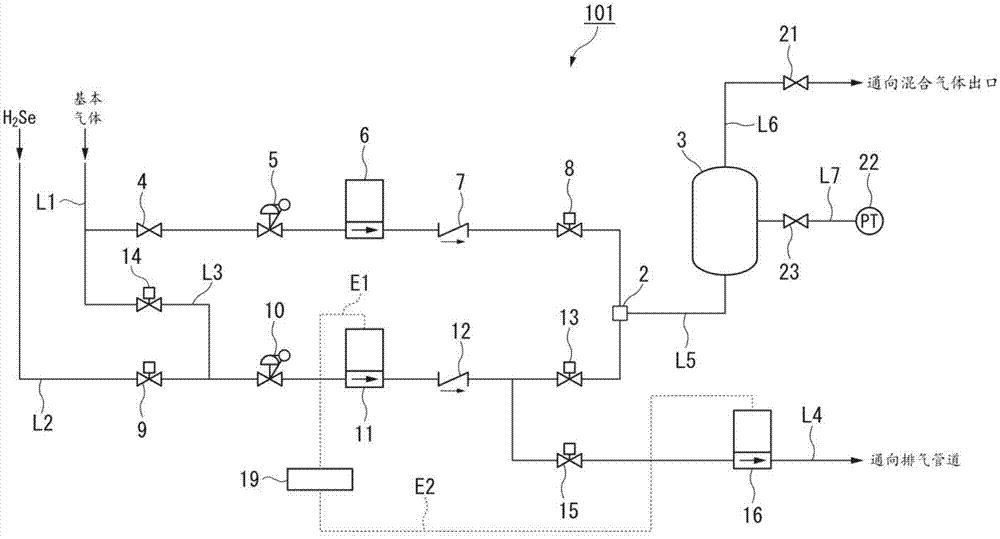

[0170] use figure 1 The shown supply device 101 produces the hydrogen-selenide mixed gas, and continuously supplies the hydrogen-selenide mixed gas to the solar cell manufacturing apparatus for a long time. When performing the manufacturing process of the hydrogen-selenide mixed gas of the supply apparatus 101, the conditions of Table 1 were used. In addition, when performing the correction process of the flow rate set value of the raw material gas of the supply apparatus 101, the conditions of Table 2 were used.

[0171] [Table 1]

[0172]

[0173] [Table 2]

[0174]

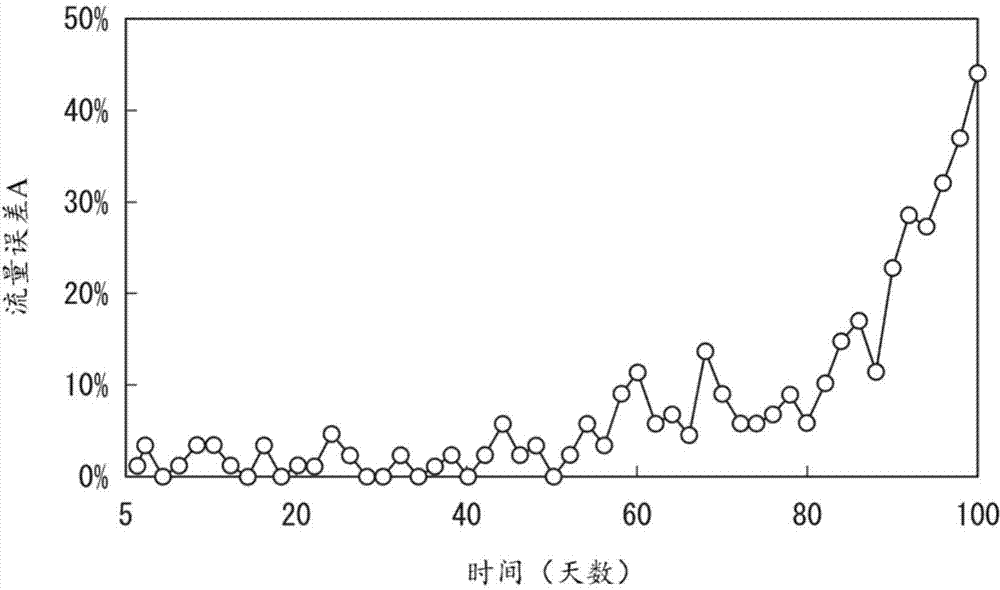

[0175] · Table 2 shows when the flow measurement value V of the mass flow controller 11 3 During the correction process, when the flow rate of the controller is displayed as 10.0L / min, the actual flow of nitrogen gas is 13.0L / min.

[0176] "Once" described in Table 2 is the number of times of combinati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap