Propylene epoxide production wastewater treatment method

A technology for the production of wastewater and propylene oxide, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of poor treatment effect, immature treatment process, and high treatment cost , to achieve the effect of improving the treatment effect, ensuring stable and up-to-standard discharge, and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

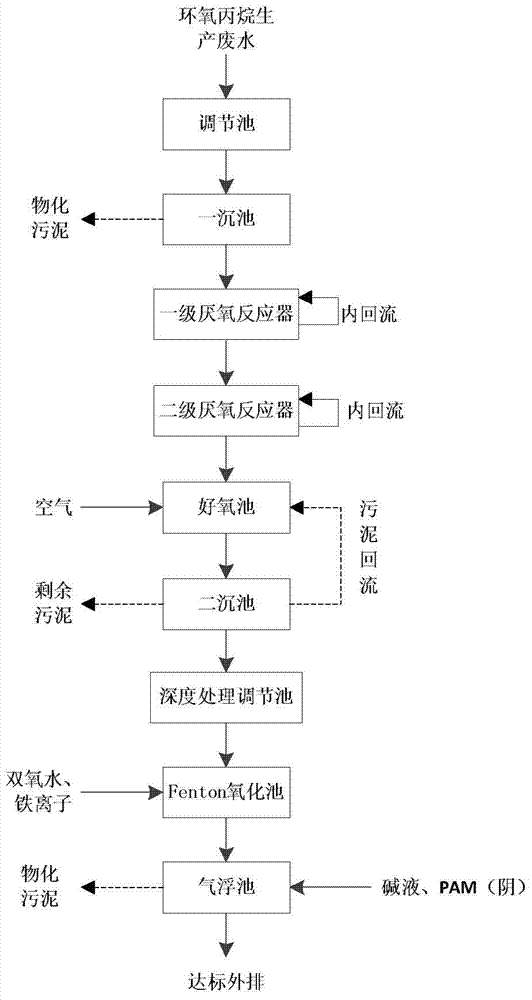

[0038] Such as figure 1 Shown, the production wastewater of a certain production propylene oxide enterprise in Jiangsu, the raw water COD concentration is about 12000mg / L, and the salinity concentration is about 7000mg / L, adopts a kind of processing method of propylene oxide production wastewater of the present invention to process it, The design processing capacity is 2000t / d, and the steps are:

[0039] (a) Homogenization: Pump the propylene oxide production wastewater to the adjustment tank for adjustment and homogenization to reduce the concentration of suspended solids in the wastewater. In the adjustment tank, the temperature of the wastewater is controlled at 30-35 ° C. The adjustment tank adopts a push-flow type The submersible mixer adjusts the water quality, and the hydraulic retention time is 48h;

[0040] (b) Sedimentation: Introduce the adjusted waste water in step (a) into a circular radial flow type primary settling tank with a diameter of 14m for precipitation...

Embodiment 2

[0050] Such as figure 1 Shown, the production wastewater of a certain production propylene oxide enterprise in Jiangsu, the raw water COD concentration is about 10000mg / L, and the salinity concentration is about 8000mg / L, adopts a kind of processing method of propylene oxide production wastewater of the present invention to process it, The design processing capacity is 1000t / d, and the steps are:

[0051] (a) Homogenization: Pump the propylene oxide production wastewater to the adjustment tank for adjustment and homogenization to reduce the concentration of suspended solids in the wastewater. The temperature of the wastewater is controlled at 30-35°C. The adjustment tank uses a push-flow submersible mixer to control the water quality. Adjustment, the hydraulic retention time in the adjustment pool is 48h;

[0052] (b) Sedimentation: Introduce the adjusted waste water in step (a) into two vertical-flow primary sedimentation tanks with a size of 6×6m for precipitation, and the ...

Embodiment 3

[0062] Such as figure 1 Shown, the production wastewater of a certain production propylene oxide enterprise in Jiangsu, the raw water COD concentration is about 8000mg / L, and the salinity concentration is about 7000mg / L, adopts a kind of processing method of propylene oxide production wastewater of the present invention to process it, The design processing capacity is 1000t / d, and the steps are:

[0063] (a) Homogenization: Pump the propylene oxide production wastewater to the adjustment tank for adjustment and homogenization to reduce the concentration of suspended solids in the wastewater. The temperature of the wastewater is controlled at 30-35°C. The adjustment tank uses a push-flow submersible mixer to control the water quality. Adjustment, the hydraulic retention time in the adjustment pool is 36h;

[0064] (b) Sedimentation: Introduce the adjusted waste water in step (a) into two vertical-flow primary sedimentation tanks with a size of 6×6m for precipitation, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com