A preparation method of modified carbon nanotubes for proton exchange membrane

A proton exchange membrane and modified carbon technology, applied in the direction of carbon nanotubes, nanocarbon, nanotechnology, etc., can solve the problems of insufficient uniformity of the proton exchange membrane, reduce the proton conductivity of the membrane, reduce the alcohol resistance of the membrane, and achieve methanol Improvement of permeability, reduction of methanol permeability, and improvement of proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

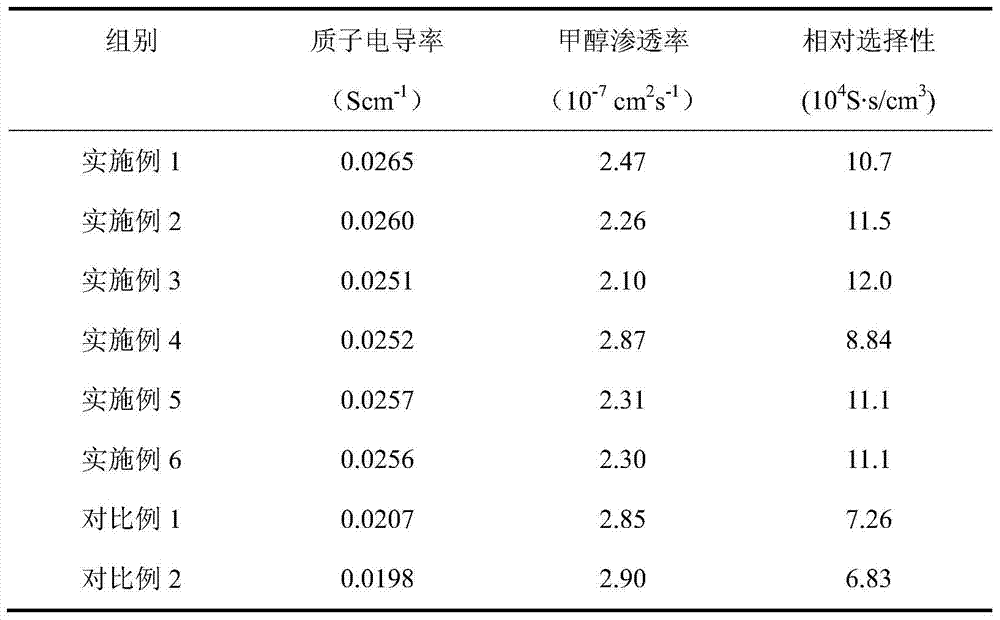

Examples

Embodiment 1

[0027] (1) prepare the ethanol solution of dopamine hydrochloride, wherein the concentration of dopamine hydrochloride is 4.0mg / mL, continuously feed nitrogen, and slowly add dropwise ammonia water (NH 3 Content 28wt%), add 1,3-propyl sultone according to the ratio of 4.0mg / mL to ethanol, reflux reaction at 50°C for 18h, then filter to obtain white powder, wash with ethanol for 3 times and dry to obtain sulfonate acidified dopamine;

[0028] (2) Dissolve tris(hydroxymethyl)aminomethane hydrochloride in deionized water to a concentration of 1.5 mg / mL, adjust the pH to 8.0 to obtain a buffer, disperse carbon nanotubes in the buffer, and add sulfonated dopamine , wherein the ratio of carbon nanotubes to buffer is 20 mg / mL, the ratio of sulfonated dopamine to buffer is 10 mg / mL, after reacting at room temperature for 48 hours, centrifuge to remove the lower precipitate and dry to obtain modified carbon nanotubes.

[0029] Disperse the above-mentioned modified carbon nanotubes eve...

Embodiment 2

[0031] (1) prepare the ethanol solution of dopamine hydrochloride, wherein the concentration of dopamine hydrochloride is 6.0mg / mL, continuously feed nitrogen, slowly add dropwise the ammoniacal liquor (NH 3 Content 25wt%), add 1,3-propyl sultone according to the ratio of 5.0mg / mL to ethanol, reflux reaction at 40°C for 24h, then filter to obtain white powder, wash with ethanol for 5 times and dry to obtain sulfonate acidified dopamine;

[0032] (2) Dissolve tris(hydroxymethyl)aminomethane hydrochloride in deionized water to a concentration of 1.0 mg / mL, adjust the pH to 11.0 to obtain a buffer, disperse carbon nanotubes into the buffer, and add sulfonated dopamine , wherein the ratio of carbon nanotubes to buffer is 30 mg / mL, the ratio of sulfonated dopamine to buffer is 6 mg / mL, after reacting at room temperature for 36 hours, centrifuge to remove the lower precipitate and dry to obtain modified carbon nanotubes.

[0033] The film-forming process of the proton exchange memb...

Embodiment 3

[0035] (1) Prepare the ethanol solution of dopamine hydrochloride, wherein the concentration of dopamine hydrochloride is 8.0mg / mL, continuously feed argon gas, slowly add dropwise ammonia water (NH 3 content 25wt%), add 1,3-propyl sultone according to the ratio of ethanol to 6.0mg / mL, reflux reaction at 60°C for 18h, then filter to obtain white powder, wash with ethanol for 4 times and dry to obtain sulfonate acidified dopamine;

[0036] (2) Dissolve tris(hydroxymethyl)aminomethane hydrochloride in deionized water to a concentration of 2.0 mg / mL, adjust the pH to 9.0 to obtain a buffer solution, disperse carbon nanotubes in the buffer solution, and add sulfonated dopamine , wherein the ratio of carbon nanotubes to buffer is 10 mg / mL, the ratio of sulfonated dopamine to buffer is 2 mg / mL, after reacting at room temperature for 24 hours, centrifuge to remove the lower precipitate and dry to obtain modified carbon nanotubes.

[0037] The film-forming process of the proton excha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com