Preparation method for black bamboo salt

A technology of purple bamboo salt and bamboo salt, applied in the field of bamboo salt processing, can solve problems such as inability to purify harmful substances in bamboo salt, and achieve the effects of reduced yield and easy boiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

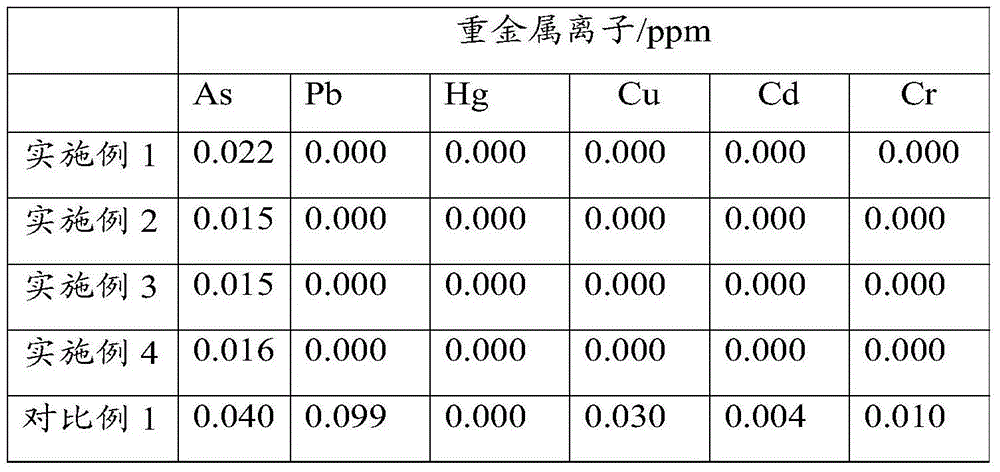

Examples

Embodiment 1

[0029] Take the steel bamboo and cut it into single-section bamboo tubes, wash them with clean water, put salt into the cut bamboo tubes after drying, and fill the salt up to 1 cm from the top of the bamboo tube wall. Apply the prepared yellow mud evenly to the top of the bamboo tube, and seal the yellow mud layer with a thickness of one centimeter. Sealed bamboo tubes are arranged in the kiln in a cross pattern to ensure full combustion in the kiln. When the temperature in the kiln reaches 300°C, maintain this temperature and continue firing for 2.5 hours. Then raise the temperature in the kiln to 500°C and keep firing at this temperature for 2 hours. Then the temperature in the kiln was raised to 800°C again, and the firing was maintained at this temperature for 1 hour. Finally, the temperature in the kiln was increased to 1200°C, and firing continued at this temperature for 1 hour.

[0030] After firing, the kiln switch is turned on, and the fired liquid salt flows into ...

Embodiment 2

[0032] Take the bamboo with a growth period of 3 years, cut it into a single-section bamboo tube, wash it with clean water, put salt into the cut bamboo tube after drying, and fill it up to 1 cm from the top of the bamboo tube wall.

[0033] Take the loess and yellow mud 10 meters deep underground, and apply it evenly to the top of the bamboo tube, and seal the yellow mud layer with a thickness of one centimeter. The sealed bamboo tubes are arranged in a crosswise arrangement in the capacitor corundum kiln, and the heating rate is set to 300°C / h to gradually increase the temperature in the kiln, and the ventilation and oxygen flow are opened during the firing process. When the temperature in the kiln reaches 320°C, maintain this temperature and continue firing for 2 hours. Then raise the temperature inside the kiln to 530°C, and keep firing at this temperature for 1 hour. Then the temperature in the kiln was raised to 850°C again, and the firing was maintained at this tempera...

Embodiment 3

[0036] Take the bamboo with a growth period of 3 years, remove the bamboo leaves and branches, and cut them into single-section bamboo tubes. The length of the unified bamboo tube is 30-40 cm, and the length is less than 30 cm or higher than 40 cm. Wash the selected bamboo tubes with clean water, dry them, and put salt into the cut bamboo tubes, filling the salt up to 1 cm from the top of the bamboo tube wall.

[0037]Take the loess and yellow mud 10 meters deep underground, and apply it evenly to the top of the bamboo tube, and seal the yellow mud layer with a thickness of one centimeter. The sealed bamboo tubes are arranged in a crosswise arrangement in the capacitor corundum kiln, and the heating rate is set to 500°C / h to gradually increase the temperature in the kiln, and the ventilation and oxygen flow are turned on during the firing process. When the temperature in the kiln reaches 300°C, maintain this temperature and continue firing for 2 hours. Then raise the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com