Preparation method and application of high-density RGD peptide modified material

A modified material and high-density technology, applied in the field of biomedicine, can solve the problems of inability to maintain cell activity, large cell damage, weak binding ability, etc., and achieve the effect of preserving integrity and activity, not easy to fall off, and strong adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

[0032] A preparation method of a high-density RGD peptide modified material, comprising the following steps:

[0033] (1) Preparation of initiator

[0034] Disperse 1 g of amino microspheres (30 μm) in 30 mL of toluene, sonicate for 10 minutes, add a catalytic amount (0.08 g) of 4-dimethylaminopyridine, slowly add 1.25 mL of triethylamine and 0.75 mL of 2-bromo For isobutyryl bromide, continue to stir for 2 hours in an ice bath, heat up to room temperature and stir for 12 hours to fully react, filter with sand core funnel, wash with toluene, acetone, and methanol in sequence, and dry under vacuum at 60°C for 12 hours. Prepare the initiator;

[0035] The reaction scheme is as follows:

[0036]

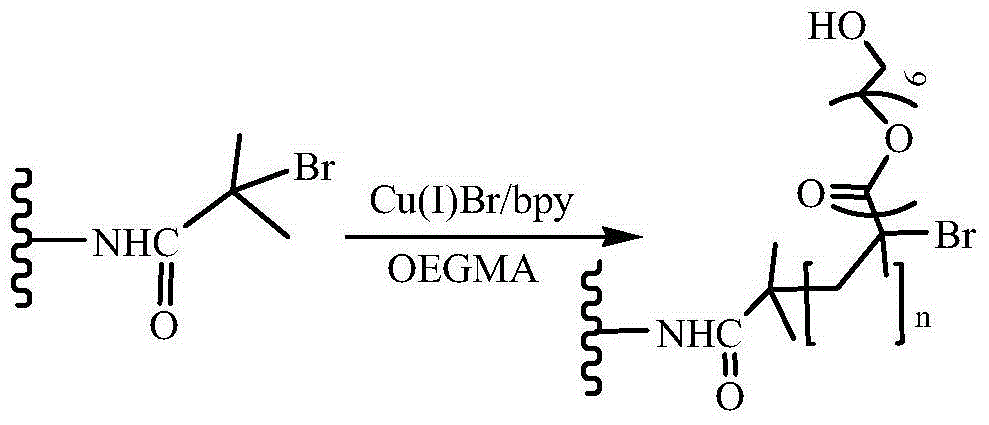

[0037] (2) Synthesis of polymer brushes

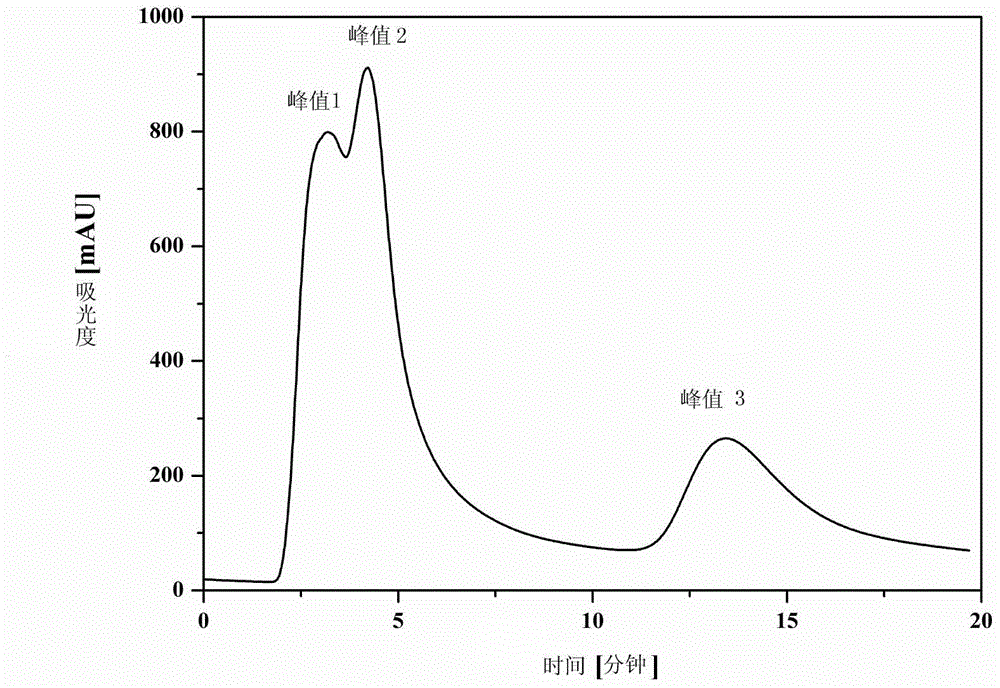

[0038] Add the initiator amino microspheres obtained in step (1) into a mixture containing polyethylene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com