Method for utilizing plasma spray scalded wear-resistant coating

A wear-resistant coating and plasma technology, applied in the field of metal material preparation, can solve the problems of affecting the protective effect of the matrix material, easy to fall off, plastic deformation, etc., achieve easy distribution and coating area, reduce the difference in alloy shrinkage ratio, The effect of improving binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The first step: raw material preparation

[0033] Powder raw materials are Fe, Ti, W, B 4 C, C, WC powder, powder particle size: Fe, Ti, W powder particle size is 61-74μm, WC, B 4 The particle size of C powder is 44-53μm, and the proportion of raw materials according to mass percentages are: 50% Fe, 15% Ti, 10% W, 10% B 4 C, 5% C, 10% WC. Put the reaction raw materials into the mixer and ball mill for 4 hours, and take them out for later use.

[0034] Step 2: Pretreatment of the workpiece surface

[0035] The purpose of the surface pretreatment of the workpiece is mainly to improve the bonding strength between the coating and the substrate. It is divided into two steps: cleaning and sandblasting: first use acetone or gasoline to completely remove the oil on the surface of the workpiece, and then sandblast the surface, remove rust and remove Oxide skin makes the surface silvery gray.

[0036] Step 3: Preparation process of wear-resistant boss (coating)

[0037] Place the workpie...

Embodiment 2

[0041] In addition to step (1), the powder raw material ratio according to mass percentages are: 80% Fe, 10% Ti, 5% W, 2% B 4 C, 3% WC, C is zero, and the main technical parameters of plasma spraying in the preparation process of step (3) wear-resistant boss (coating) are set as: current 100A, voltage 30V, gas Ar+N 2 Total air volume 6L / min, N 2 The air volume is 10%, and the powder feeding volume: 50g / min. Except for the parameter changes in the above two steps, the other processes and parameters are the same as the first embodiment.

[0042] The height of the finally obtained wear-resistant boss is 5mm, the average diameter of the boss is about 10mm, the scaly hardened area formed by the boss accounts for 80% of the surface area of the whole workpiece, and the surface hardness of the boss can reach HRC58-60.

Embodiment 3

[0044] In addition to step (1), the proportion of powder raw materials according to mass percentages are: 65% Fe, 12% Ti, 8% W, 6% B 4 In addition to C, 4% C, and 5% WC, the main technical parameters of plasma spraying in the preparation process of step (3) wear-resistant boss (coating) are set as follows: current 150A, voltage 40V, Ar+N 2 Total air volume: 4.5L / min, N 2 The air volume is 20%, and the powder feeding volume is 30 g / min. Except for the parameter changes in the above two steps, the other processes and parameters are the same as in the first embodiment.

[0045] The final height of the wear-resistant boss is 4mm, the average diameter of the boss is about 13mm, the scaly hardened area formed by the boss accounts for 65% of the total surface area of the workpiece, and the surface hardness of the boss can reach HRC60-62.

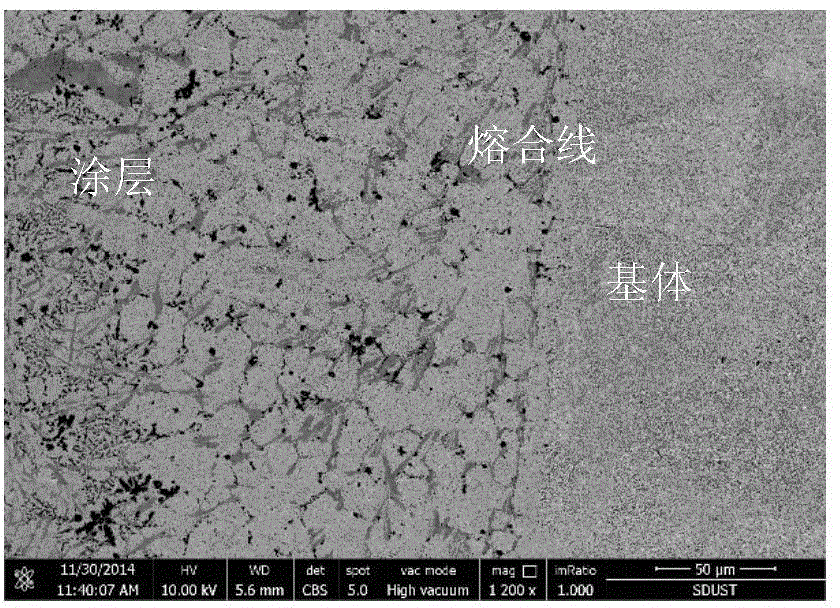

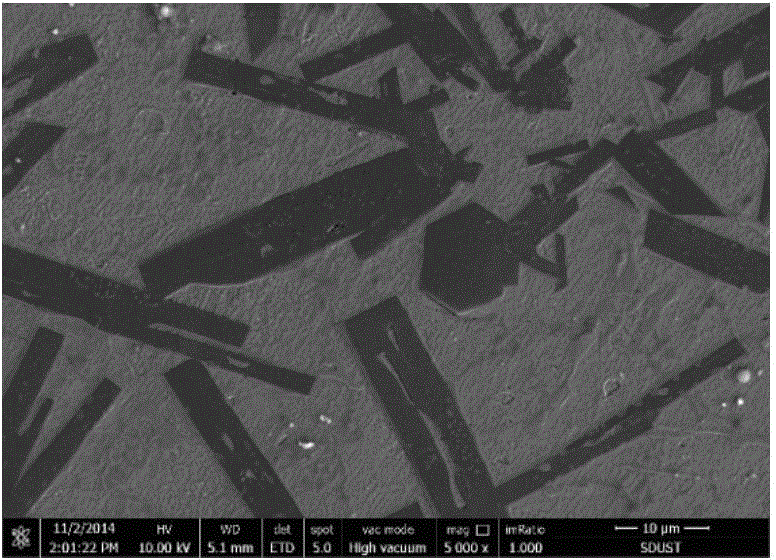

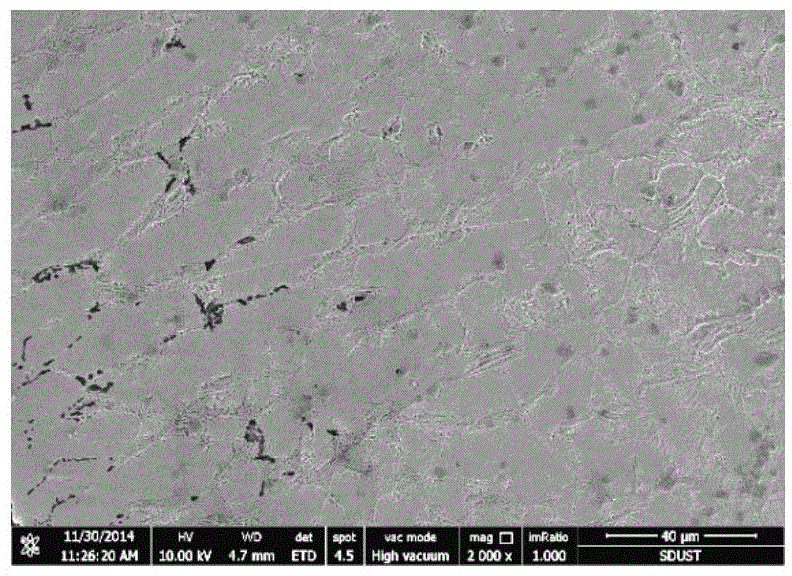

[0046] From the coating structure of the present invention figure 1 It can be seen that there is a rapid melting transition zone between the cermet coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com