Improved seed crude enzyme solution extracting method

A technology of seed crude enzyme and extraction method, which is applied in the preparation of test samples and the measurement of color/spectral properties, etc. Improved repeatability and cost savings of assays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

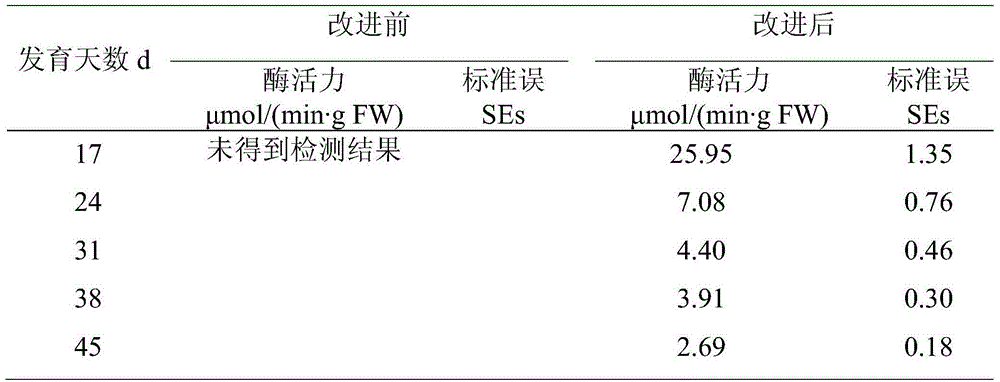

[0027] Example 1. Improved glutamate synthase activity assay method

[0028] Preparation of modified glutamic acid synthetase extract (50mM phosphate buffer solution with pH=7.2, 5% v / v glycerol, 2% w / v polyvinylpyrrolidone): measure the original extract solution with 50mM phosphate buffer solution with pH=7.2 Liquid 95ml, glycerin 5ml and 0.2g polyvinylpyrrolidone are mixed evenly. The above extract was stored at 4°C; glycerol was the volume percentage concentration, and polyvinylpyrrolidone was the mass concentration (that is, 2 g of polyvinylpyrrolidone was added to 1 L of the improved extract).

[0029] Sampling: Select cotton plants with consistent growth, when 50% of the 1st and 2nd fruiting nodes of cotton 6-8 fruiting branches bloom, put a sign to mark the white flowers on the 1st and 2nd fruiting nodes of the cotton middle fruiting branches. 10 days, 17 days, 24 days, 31 days, 38 days, 45 days after flowering, 6-8 cotton bolls with consistent growth and development w...

Embodiment 2

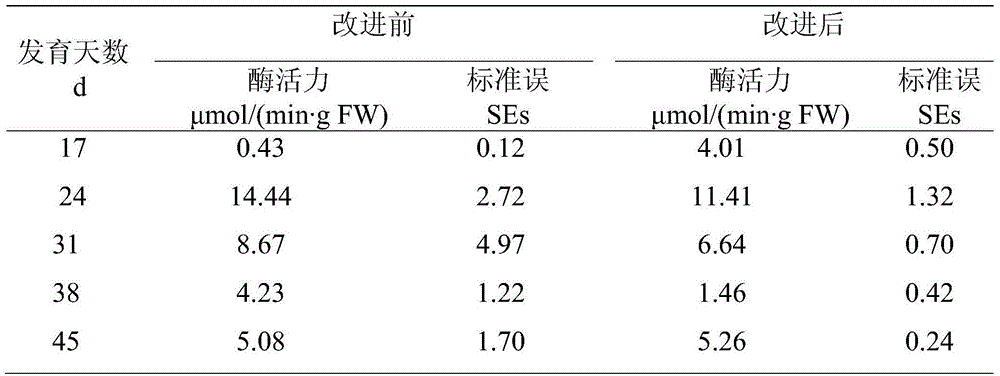

[0040] Embodiment 2. The assay method of improved phosphoenolpyruvate carboxylase enzyme activity

[0041] Prepare phosphoenolpyruvate carboxylase modified extract (300mM sucrose, 50mM pH=7.0Hepes-Tris, 8mM EDTA, 2mM PMSF, 4mM DTT, 5% v / v glycerol, 2% w / v polyethylene Pyrrolidone): Measure 95ml of the original extract (300mM sucrose, 50mM pH=7.0Hepes-Tris, 8mM EDTA, 2mM PMSF, 4mM DTT), 5ml of glycerin and 0.2g of polyvinylpyrrolidone and mix well. The above extract was stored at 4°C; glycerol was the volume percentage concentration, and polyvinylpyrrolidone was the mass concentration (that is, 2 g of polyvinylpyrrolidone was added to 1 L of the improved extract).

[0042]Sampling: Select cotton plants with consistent growth, when 50% of the 1st and 2nd fruiting nodes of cotton 6-8 fruiting branches bloom, put a sign to mark the white flowers on the 1st and 2nd fruiting nodes of the cotton middle fruiting branches. 10 days, 17 days, 24 days, 31 days, 38 days, 45 days after flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com