Method for growth and preparation of III-nitride Schottky barrier diode

A Schottky potential, nitride technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as reducing the performance of Schottky diodes, achieve simple structure, low reverse leakage current, and improve resistance The effect of pressure characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

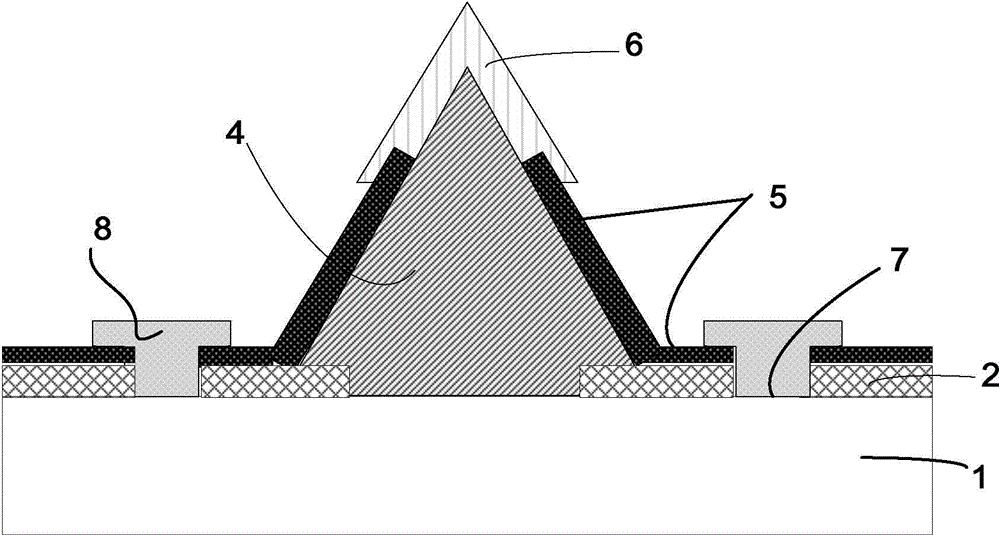

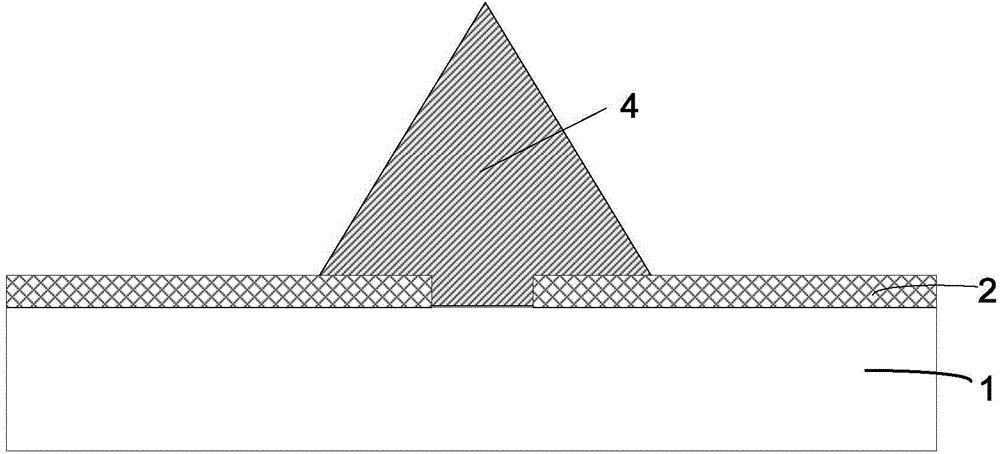

[0036] attached figure 1It is a schematic diagram of the design of Embodiment 1, which combines vertical and horizontal conductive structures. The basic structure includes: substrate 1 , mask layer 2 , selective growth window 3 , epitaxially grown III-nitride three-dimensional structure 4 , barrier layer 5 , Schottky contact layer 6 , and ohmic contact layer 7 . Combine below Figure 2a -2e describes the manufacturing process of embodiment 1 in detail.

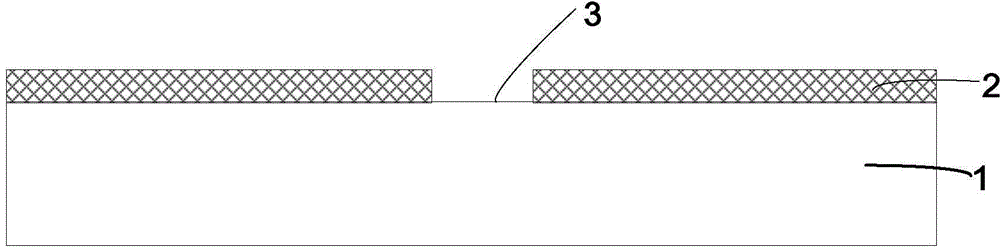

[0037] see Figure 2a , provide an underlying substrate 1, the material of the underlying substrate 1 can be Si, GaN, ZnO, AlN, AlGaN, Al 2 o 3 , diamond, SiC and other bulk materials, and a composite substrate material formed of a single-layer or multi-layer III-nitride material or ZnO material grown on the above-mentioned bulk material substrate can also be selected. A mask layer 2 is then deposited on the substrate 1 . The material of the mask layer 2 can be selected from high-resistance materials such as SiO2, SiN, A...

Embodiment 2

[0044] as attached Figure 6 As shown, it is a cross-sectional view of another III-nitride Schottky barrier diode combining vertical and lateral conductive structures of the present invention. The structure in this embodiment is basically the same as that in Embodiment 1, except that the metal layer of the Schottky contact layer 6 extends to the top of the entire three-dimensional structure 4 and overlaps with the barrier layer 5 . The advantage of embodiment 2 compared with embodiment 1 is that embodiment 2 has a field plate structure, which effectively avoids the edge effect of current and is conducive to conduction of a larger forward current. FIG. 7 is a perspective view of a group-III nitride Schottky barrier diode with a hexagonal pyramid structure prepared based on Example 2. FIG.

Embodiment 3

[0046] as attached Figure 8 Shown is Embodiment 3 of the present invention, a cross-sectional view of a group-III nitride Schottky barrier diode with a vertical conduction structure. The structure in this embodiment is basically the same as that in Embodiment 1, except that the ohmic contact layer 8 is located on the back of the substrate 1 and forms a good ohmic contact with the substrate 1 . Embodiment 3 does not need to etch the through-hole structure 7, the process is relatively simple, and the Schottky contact layer and the ohmic contact layer of the structure are located on the upper and lower surfaces of the device, so that the device has vertical conduction characteristics and avoids current edge collection effect, it is convenient to realize parallel packaging of multiple devices. Accompanying drawing 9 is the perspective view of a group-III nitride Schottky barrier diode with a strip-shaped three-dimensional structure prepared based on Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com