Viscoelastic solution containing trimeric anionic surfactant component and preparation method thereof

A surfactant and polyanion technology, which is applied in the preparation of organic compounds, oxygen-containing compounds, chemical instruments and methods, etc., can solve the problems of high surfactant concentration and difficult post-processing, and achieve the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: the synthesis of α-bromotetradecanoic acid methyl ester. Add tetradecanoic acid (150g, 0.6568mol) into a 500ml three-necked flask, melt at 65°C, slowly add thionyl chloride (106.6g, 0.821mol) dropwise under stirring, raise the temperature to 90°C after the dropwise addition, add A little elemental iodine was used as an initiator, and liquid bromine (131.2g, 0.821mol) dried by concentrated sulfuric acid was slowly added dropwise, stirred and refluxed for 12 hours, and the temperature was lowered to 65°C, and anhydrous methanol (52.6g, 1.64mol) was added dropwise with stirring. mol), reflux for 2-4 hours after the addition. After cooling, wash with water 3-4 times, then wash the organic layer with 50 ml of saturated sodium sulfite solution until neutral, and finally wash with water 3-4 times. The organic layer was dried overnight by adding anhydrous magnesium sulfate. After filtration, the crude product was distilled under reduced pressure to obtain α-brom...

Embodiment 2

[0016] Embodiment 2: the synthesis of anionic trimeric surfactant. Add phloroglucinol (2g, 0.016mol)\activated molecular sieve-treated N,N-dimethylformamide (30ml) into a 250ml three-necked flask, and nitrogen atmosphere prevents phenol oxidation. Add anhydrous potassium carbonate (18g, 0.13mol) and N,N-dimethylformamide (20ml), heat up to 60°C, add α-bromotetradecanoic acid methyl ester (17.8g, 0.056) in one go (dissolved In N,N-dimethylformamide), after 4h, the temperature was raised to 85°C, and the reaction was carried out for 24 hours. After cooling, a yellow filtrate was obtained by suction filtration, and N,N-dimethylformamide in the filtrate was removed under reduced pressure. Transfer the filtrate to a separatory funnel, first add 30ml of petroleum ether, and then add 50ml of ice water each time to extract the organic layer for 3-4 times. Add anhydrous magnesium sulfate to dry, remove petroleum ether under reduced pressure after filtration, and separate by column ch...

Embodiment 3

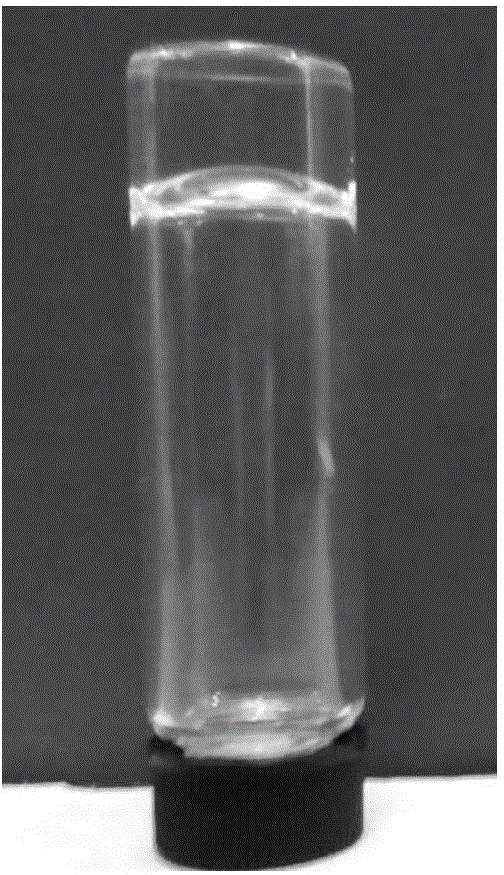

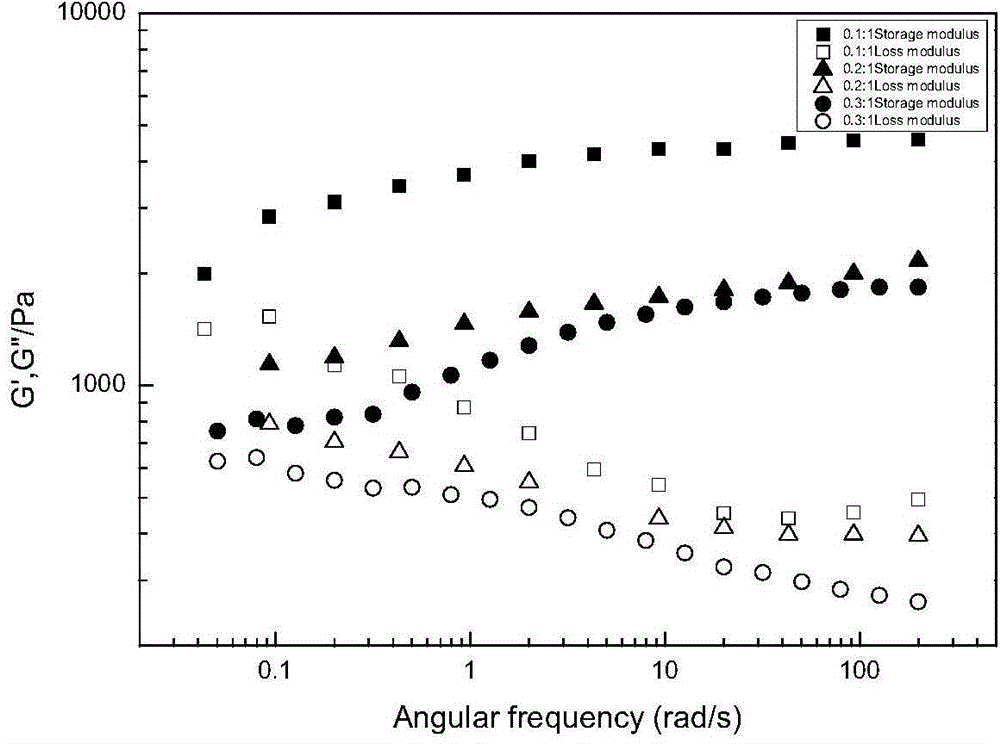

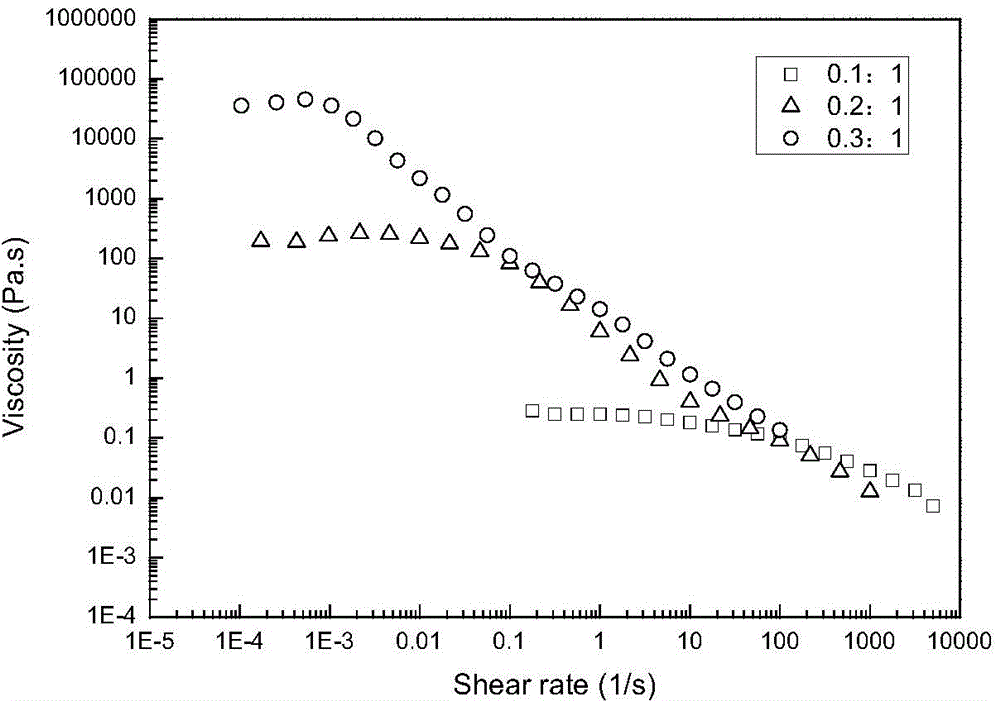

[0017] Embodiment 3: the preparation of viscoelastic surfactant solution. Prepare 3ml of trimeric surfactant solution of 50mmol / L, add appropriate amount of cationic surfactant solid to it respectively, make the molar ratio of anionic surfactant and cationic surfactant reach 1:0.1, 1:0.2 and 1 respectively :0.3, a series of viscoelastic surfactant solutions are obtained after dissolving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com