Preparation method of porous SiO2 coated nano TiO2 particles

A nano-particle technology, which is applied in the field of preparation of porous SiO2-coated nano-TiO2 particles, can solve the problems of difficult reaction activity factor, lower reaction efficiency, and influence on photocatalytic reaction rate, and achieve low cost, simple process, and adjustable pore size. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

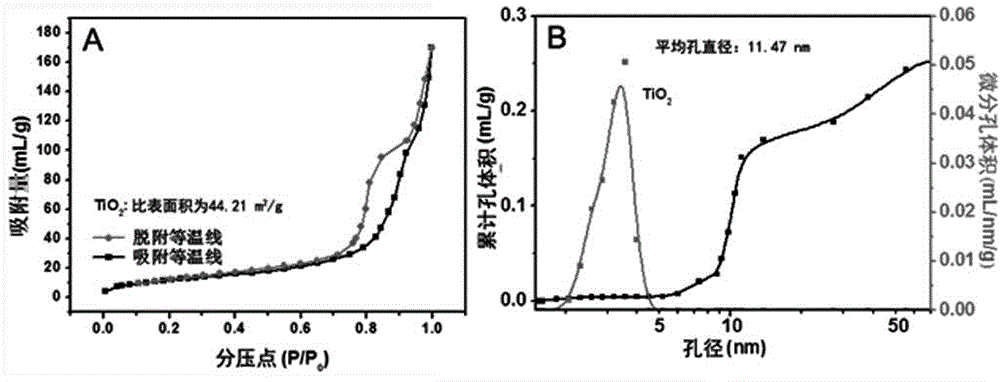

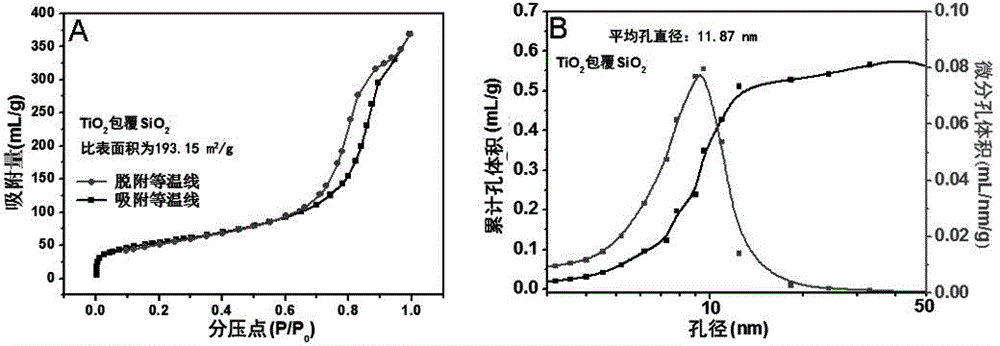

[0024] 2.0g TiO 2 1.5g of polyvinylpyrrolidone was added to 200mL of ethanol, then stirred at room temperature for 10min at a speed of 500r / min, then 1.5g of sodium polystyrene sulfonate was added, and stirred at room temperature for 10min; then 1.0g of normal Slowly add the mixed solution of butyl silicate and 1.5g methyl orthosilicate into the mixed solution, mechanically stir at room temperature at a speed of 500r / min for 10min, then raise the temperature to 60°C and continue stirring for 60min to fully react. After the reaction, cool at room temperature and filter, dry the obtained solid product and then calcinate at 600°C for 3 hours to obtain mesoporous SiO 2 Coated Nano TiO 2 composite particles.

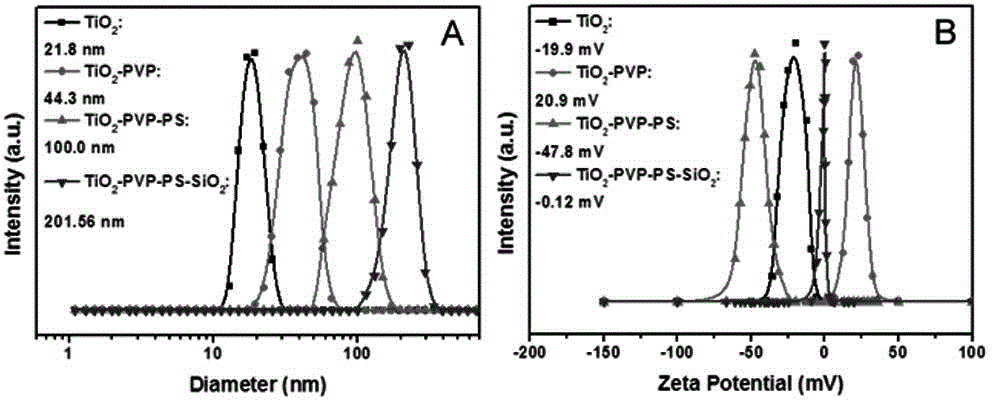

[0025] Depend on figure 1 It can be seen that A is the particle size distribution map, B is the Zeta potential map of the particle surface, and TiO 2 The average particle size of the nanoparticles was 21.8 nm, and the Zeta potential was -19.9 mV. After electrostatic adso...

Embodiment 2

[0030] 2.0g TiO 2 1.5g of polyvinylpyrrolidone was added to 200mL of water and ethanol mixed solution (volume ratio: 1:1), mechanically stirred at room temperature, the speed was 1000r / min, and the time was 10min; 2.0g of ethyl orthosilicate The ester was slowly added into the mixed solution, mechanically stirred at a speed of 200r / min at room temperature for 10min, and then the temperature was raised to 70°C and continued to stir for 30min to fully react. After the reaction, cool at room temperature and filter, dry the solid product and then calcinate at 650°C for 2 hours to obtain mesoporous SiO 2 Coated Nano TiO 2 composite particles.

Embodiment 3

[0032] 2.0g TiO 2 1.5g of polyvinylpyrrolidone was added to 200mL of glycerol, mechanically stirred at room temperature, the rotating speed was 500r / min, and the time was 20min; then 1.5g of sodium dodecylsulfonate was added, and stirring was continued for 10min at room temperature ; Slowly add 2.5g butyl orthosilicate into the mixed solution, stir mechanically at room temperature at a speed of 500r / min for 10min, then raise the temperature to 60°C and continue stirring for 60min to fully react. After the reaction, cool at room temperature and filter, dry the obtained solid product and then calcinate at 500°C for 3.5h to obtain mesoporous SiO 2 Coated Nano TiO 2 composite particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com