Bismuth oxyfluoride photocatalyst and preparing method of bismuth oxyfluoride photocatalyst

A photocatalyst, bismuth oxyfluoride technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc. The effect of good shape, high catalytic activity and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Bi 7 O 5 F 11 Preparation of Bismuth Oxyfluoride Photocatalyst

[0031] (1) Preparation of glacial acetic acid solution: add 30ml of glacial acetic acid to 30ml of water, that is, mix glacial acetic acid and water at a volume ratio of 1:1, and stir;

[0032] (2) Dissolving in a water bath: take 30ml of glacial acetic acid solution, add 0.4851g (1mmol) of bismuth nitrate pentahydrate and 0.0840g (2mmol) of sodium fluoride, stir in a constant temperature water bath at 80°C for 30 minutes, and dissolve the bismuth nitrate and sodium fluoride to obtain mixture;

[0033] (3) Hydrothermal reaction: Add the above mixed solution into the polytetrafluoroethylene lining, conduct a hydrothermal reaction at a constant temperature of 150°C for 10.5 hours, centrifuge at 3000 rpm for 3 minutes, wash with distilled water and absolute ethanol in turn, and dry at 60°C for 4 hours , that is Bi 7 o 5 f 11 Bismuth oxyfluoride photocatalyst.

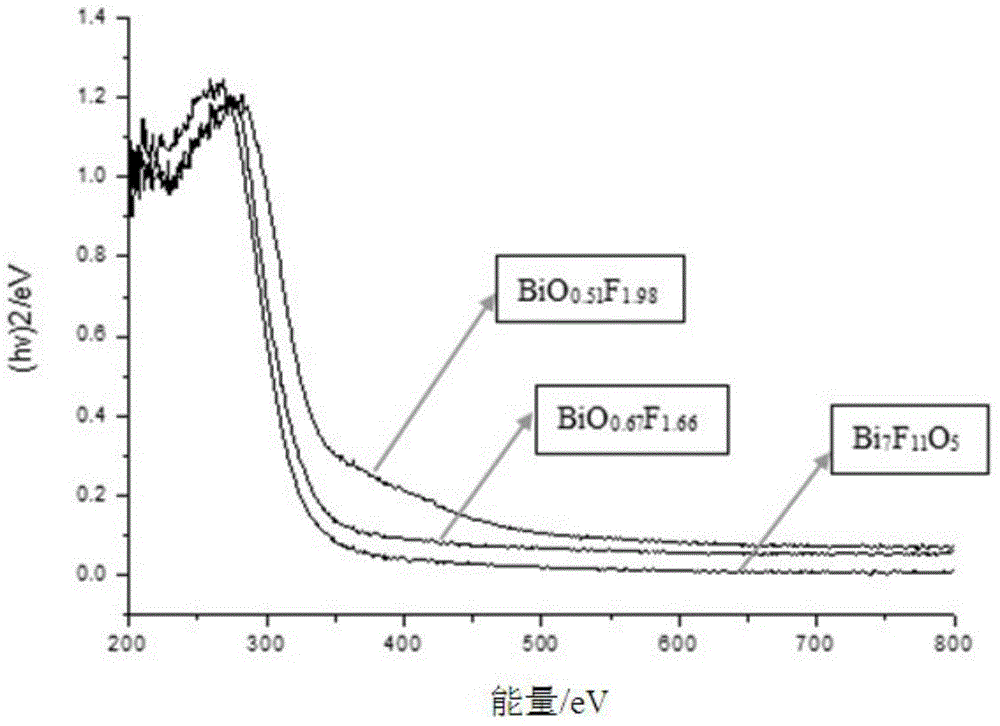

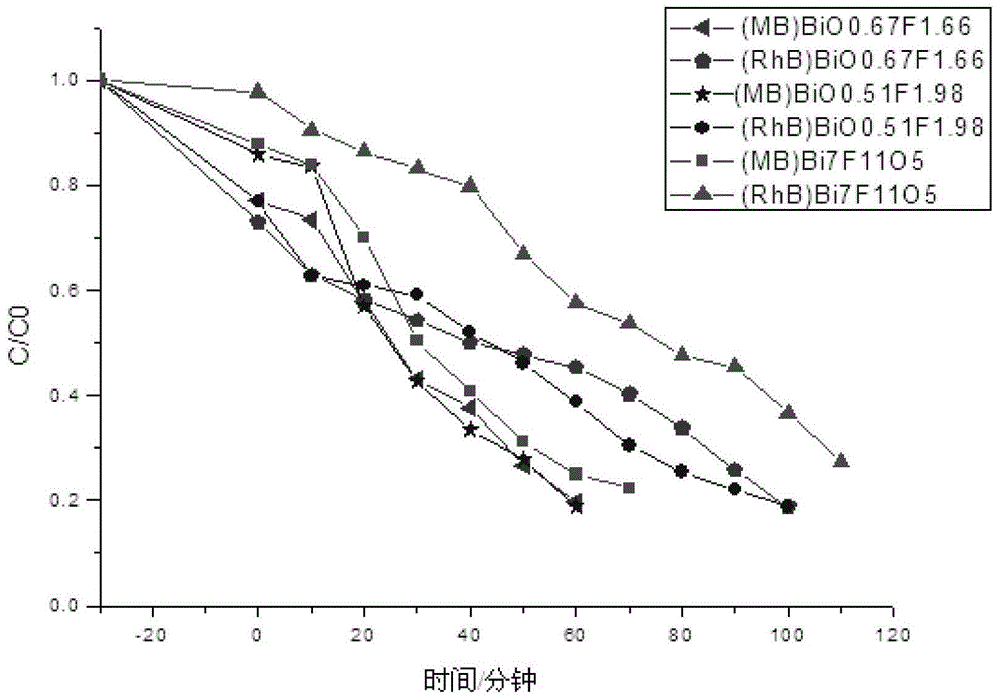

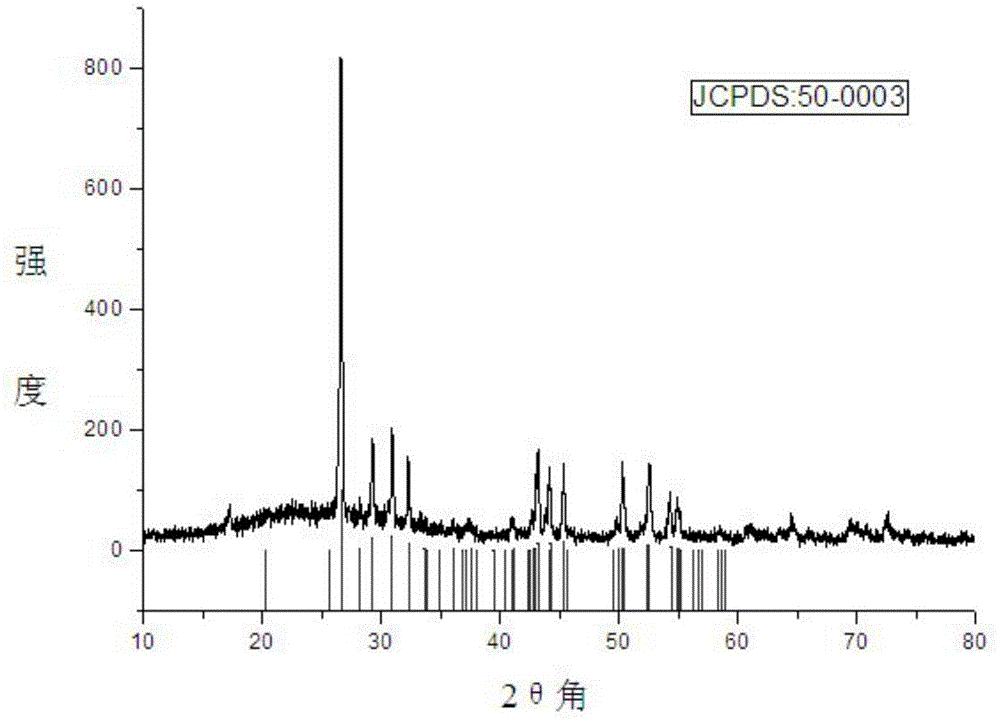

[0034] Depend on ...

Embodiment 2

[0035] Example 2: BiO 0.51 F 1.98 Preparation of Bismuth Oxyfluoride Photocatalyst

[0036] (1) Preparation of glacial acetic acid solution: add 30ml of glacial acetic acid to 30ml of water, that is, mix glacial acetic acid and water at a volume ratio of 1:1, and stir;

[0037] (2) Dissolving in a water bath: take 30ml of glacial acetic acid solution, add 0.4851g (1mmol) of bismuth nitrate pentahydrate and 0.0840g (2mmol) of sodium fluoride, stir in a constant temperature water bath at 80°C for 30 minutes, and dissolve the bismuth nitrate and sodium fluoride to obtain mixture;

[0038] (3) Hydrothermal reaction: Add the above mixed solution into the polytetrafluoroethylene lining, conduct a hydrothermal reaction at a constant temperature of 150°C for 11.5 hours, centrifuge at 3000 rpm for 3 minutes, wash with distilled water and absolute ethanol in turn, and dry at 60°C for 4 hours , namely BiO 0.51 f 1.98 Bismuth oxyfluoride photocatalyst.

[0039] Depend on ...

Embodiment 3

[0040] Example 3: BiO 0.67 F 1.66 Preparation of Bismuth Oxyfluoride Photocatalyst

[0041] (1) Preparation of glacial acetic acid solution: add 30ml of glacial acetic acid to 30ml of water, that is, mix glacial acetic acid and water at a volume ratio of 1:1, and stir;

[0042] (2) Dissolving in a water bath: take 30ml of glacial acetic acid solution, add 0.4851g (1mmol) of bismuth nitrate pentahydrate and 0.0840g (2mmol) of sodium fluoride, stir in a constant temperature water bath at 80°C for 30 minutes, and dissolve the bismuth nitrate and sodium fluoride to obtain mixture;

[0043] (3) Hydrothermal reaction: Add the above mixed solution into the polytetrafluoroethylene lining, conduct a hydrothermal reaction at a constant temperature of 150°C for 12.5 hours, centrifuge at 3000 rpm for 3 minutes, wash with distilled water and absolute ethanol in turn, and dry at 60°C for 4 hours , namely BiO 0.67 f 1.66 Bismuth oxyfluoride photocatalyst.

[0044] Depend on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com