Recycling system and recycling process for recycling salt from desulfurization waste water

A desulfurization wastewater and recycling system technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, alkali metal chloride, etc., can solve problems such as affecting salt purity, and achieve the effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

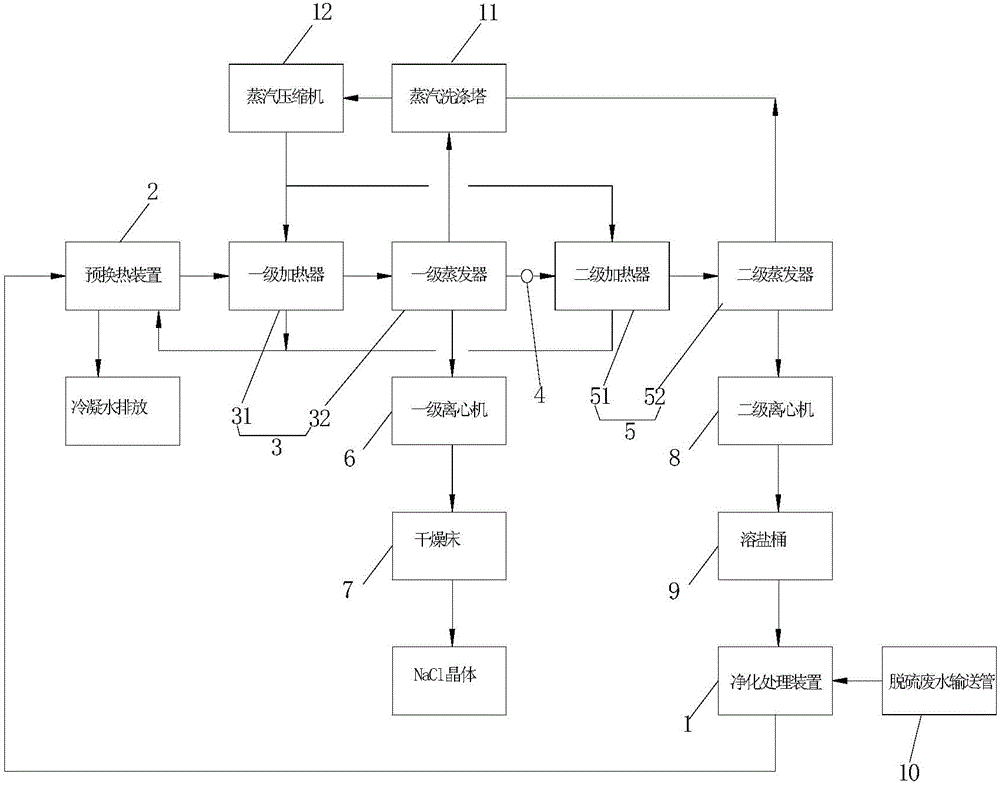

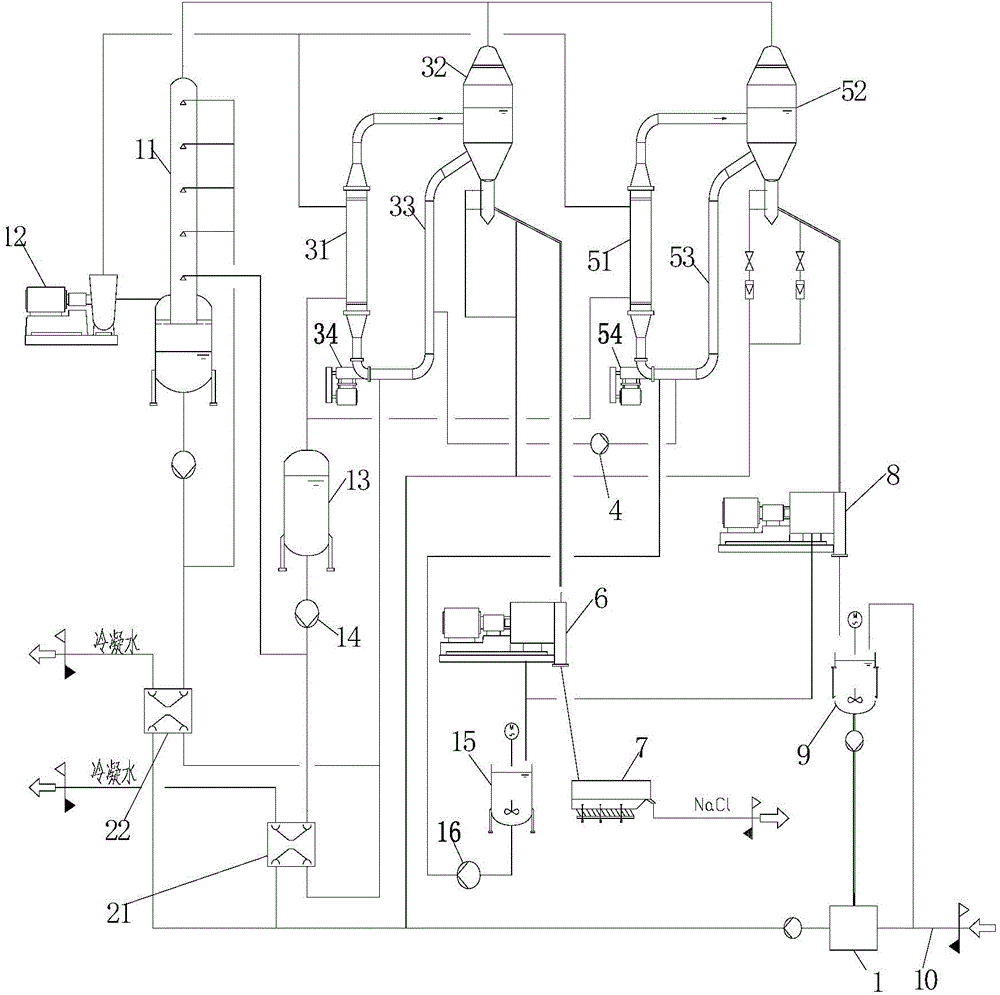

[0033] refer to Figure 1-2 , a recovery system for recovering salt from desulfurization wastewater described in this embodiment includes a purification treatment device 1, a pre-heat exchange device 2, a primary evaporative crystallization device 3, a primary transfer pump 4, and a secondary evaporative crystallization device 5. The first-stage centrifuge 6, the drying bed 7, the second-stage centrifuge 8 and the salt-dissolving barrel 9; the purification treatment device 1 is a demineralized water device.

[0034] One of the water inlets of the purification treatment device 1 is connected to the desulfurization waste water conveying pipe 10, and the water outlet of the purification treatment device 1 is connected to the preheat exchange device 2 and the primary evaporative crystallization device 3 through pipes in turn; the primary evaporative crystallization The primary concentrated brine output port of the device 3 is connected to the secondary evaporative crystallization ...

Embodiment 1

[0060] Example 1: Evaporation at 50°C

[0061] The solubility components of sodium chloride-sodium sulfate-water are shown in Table 3:

[0062] Table 3 Solubility of sodium chloride-sodium sulfate-water at 50℃

[0063]

[0064]

[0065] According to the mutual solubility relationship between sodium chloride and sodium sulfate at 50 °C, the first-stage evaporation should control the sodium sulfate component to be less than 5.3%, and the sodium chloride component to be greater than 24.2%, so that sodium chloride crystals can be precipitated, while Sodium sulfate did not precipitate. That is, the primary evaporation is:

[0066] M (Na2SO4) / (M 总 -M 蒸发 )*100%<5.3%;

[0067] M 蒸发 总 -M (Na2SO4) *100% / 5.3%;

[0068] M 蒸发 <15943.2-317.3*100% / 5.3%Kg / h;

[0069] i.e. M 蒸发 <9956.4Kg / h;

[0070] At this moment, the sodium chloride component content is: M(NaCl) / (M total-M evaporation)*100%=2900 / (15943.2-9956.4)*100%=48.44%;

[0071] When the solubility of sodium chlorid...

Embodiment 2

[0078] Example 2: Evaporation at 75°C

[0079] The solubility components of sodium chloride-sodium sulfate-water are shown in Table 4:

[0080] Table 4 Solubility of sodium chloride-sodium sulfate-water at 75℃

[0081]

[0082] According to the mutual solubility relationship between sodium chloride and sodium sulfate at 75 °C, the first-stage evaporation should control the sodium sulfate component to be less than 4.95%, and the sodium chloride component to be greater than 25.25%, so that pure sodium chloride crystals can be precipitated. The sodium sulfate did not precipitate. That is, the primary evaporation is:

[0083] M (Na2SO4) / (M 总 -M 蒸发 )*100%<4.95%;

[0084] M 蒸发 总 -M (Na2SO4) *100% / 4.95%;

[0085] M 蒸发 <15943.2-317.3*100% / 4.95%Kg / h;

[0086] i.e. M 蒸发 <9533.1Kg / h;

[0087] At this time, the sodium chloride component content is:

[0088] M (NaCl) / (M 总 -M 蒸发 )*100%=2900 / (15943.2-9533.1)*100%=45.24%;

[0089] When the solubility of sodium chloride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com