Method for preparing high-purity 4-hydroxyethyl piperazine ethane sulfonic acid

A technology of hydroxyethylpiperazine ethanesulfonic acid and hydroxyethylpiperazine is applied in the field of preparation of high-purity 4-hydroxyethylpiperazine ethanesulfonic acid, and can solve environmental pollution, consumption of large acids and bases, and high cost problem, to achieve the effect of simple operation process, low purification cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

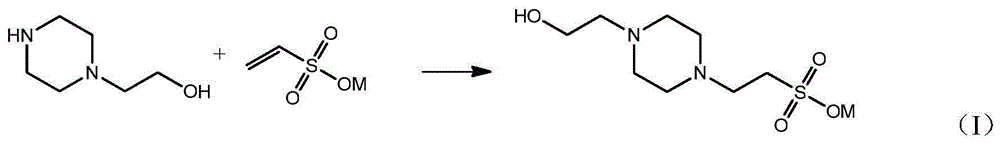

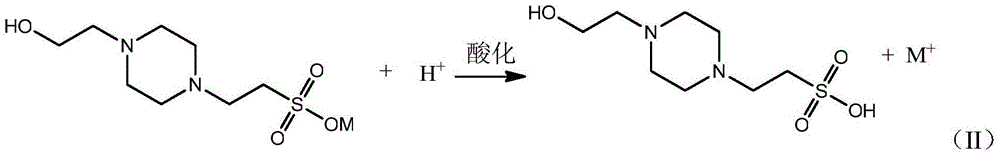

Method used

Image

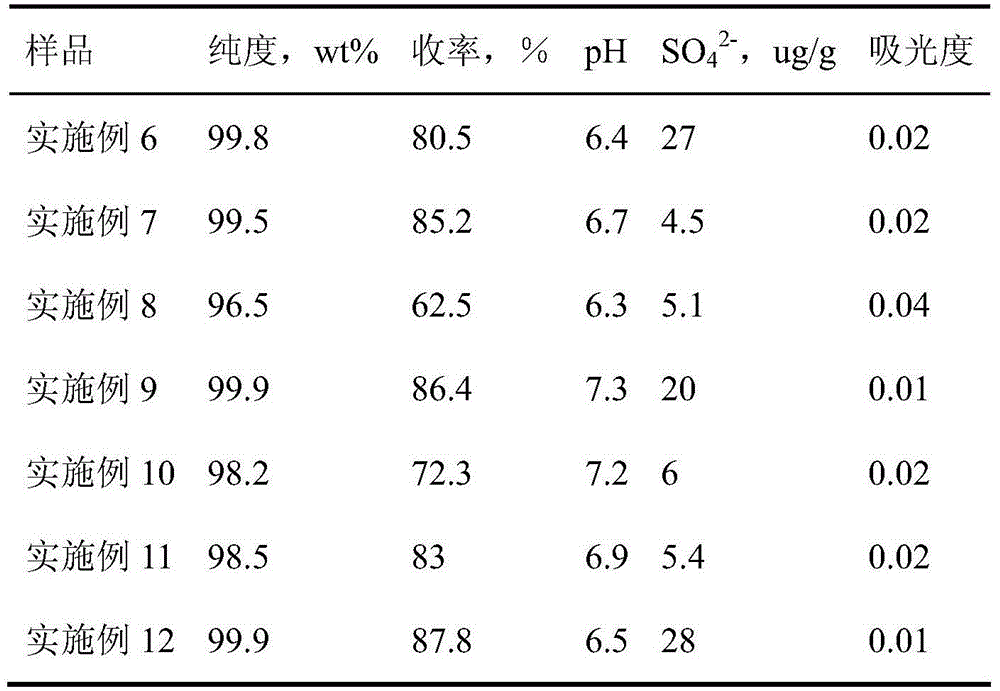

Examples

Embodiment 1

[0048] Add 131.5g N-hydroxyethylpiperazine (purity: 99%, about 1mol) and 30% (mass concentration) sodium vinylsulfonate aqueous solution (containing 1.05mol sodium vinylsulfonate) into 1000mL four Addition reaction was carried out under sufficient stirring; first reacted at 60°C for 1.0 hour, then gradually heated to boiling reflux (about 100-120°C, depending on the composition of the reaction solution), and continued to react for 2.0 hours; then , cooling to obtain a reaction mother liquor containing 4-hydroxyethylpiperazine sodium ethanesulfonate. Through high-performance liquid chromatography analysis, the calculated yield of sodium 4-hydroxyethylpiperazineethanesulfonate was 95.2%.

Embodiment 2

[0050] Add 1 mol N-hydroxyethylpiperazine and 35% (mass concentration) sodium vinyl sulfonate aqueous solution (containing 1.15 mol sodium vinyl sulfonate) into a 1000 mL four-necked flask with a reflux tube, and add them under sufficient stirring. reaction; first react at 50°C for 2.0 hours, then gradually increase the temperature to boil and reflux, and continue to react for 3.0 hours; then, cool down to obtain a reaction mother liquor containing sodium 4-hydroxyethylpiperazineethanesulfonate. Through high performance liquid chromatography analysis, the calculated yield of sodium 4-hydroxyethylpiperazineethanesulfonate was 96.4%.

Embodiment 3

[0052] Add 1mol N-hydroxyethylpiperazine and 30% (mass concentration) vinylsulfonic acid aqueous solution (containing 1.00mol vinylsulfonic acid) into a 1000mL four-necked flask with a reflux tube, and then slowly dropwise add Aqueous sodium hydroxide solution (mass concentration is 30%, containing 1.1mol sodium hydroxide); then react at 40°C for 2.0 hours, then gradually heat up and boil to reflux, and continue to react for 1.5 hours; then, cool down to obtain 4-hydroxyethyl Reaction mother liquor of sodium piperazine ethanesulfonate. Through high-performance liquid chromatography analysis, the calculated yield of sodium 4-hydroxyethylpiperazineethanesulfonate was 87.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com