Preparation method of multifunctional group bionic mussel adhesive protein polymer

A technology of mussel adhesion protein and polymer, which is applied in the direction of coating, etc., can solve the problems of poor physical adhesion strength, high price, and large difference at the interface, and achieve the effect of enhancing adhesion strength and improving adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

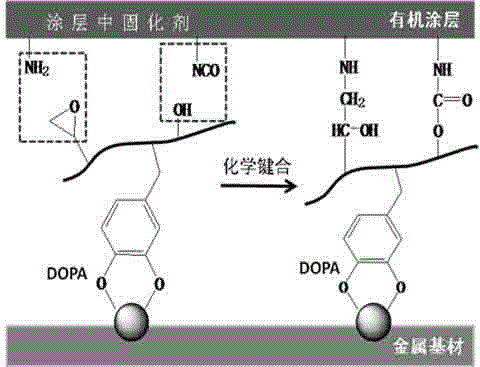

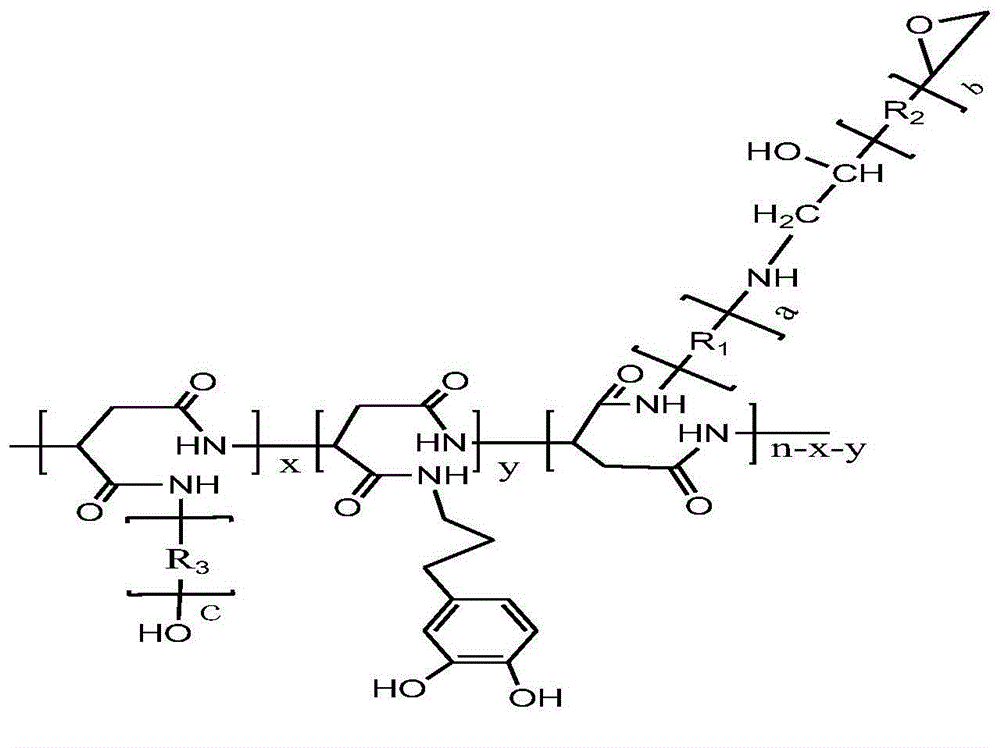

[0034] The invention relates to a method for preparing a multifunctional biomimetic mussel adhesion protein polymer. The prepared biomimetic mussel adhesion protein polymer PHEA-DOPA-EP has catechol, hydroxyl and epoxy multifunctional groups.

[0035] to combine Figure 1-2 , four reaction processes of the present invention are as follows:

[0036]

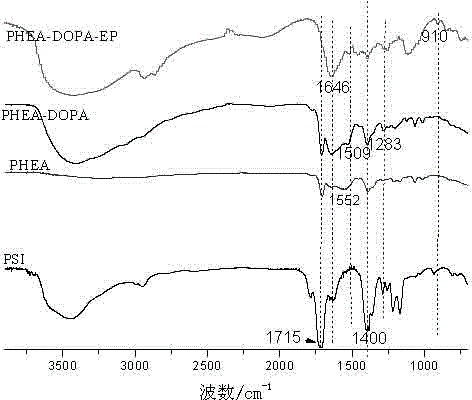

[0037] In the infrared spectrum of synthetically prepared polysuccinimide, 1715cm -1 ,1400cm -1 It is the characteristic peak of imide five-membered ring.

[0038] After preparing PHEA by ring-opening synthesis of alkanolamine EA, there is an extra 1646cm -1 (Amide I belt), 1552cm -1 (amide II band) peak, simultaneously 1715cm -1 、1400cm -1 The peak still exists and its intensity weakens, indicating that EA has been successfully grafted to the resin structure.

[0039] After connecting DOPA on PHEA, it can be at 1646cm -1 (broad peak), 1552cm -1 、1509cm -1 The place shows the introduction of benzene ring, 1283cm -1 、...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com