Method for preparing structural type wave-absorbing material

A wave-absorbing material and structure-type technology, which is applied in the field of preparing structure-type wave-absorbing materials, achieves the effect of wide wave-absorbing frequency band, low equipment requirements, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

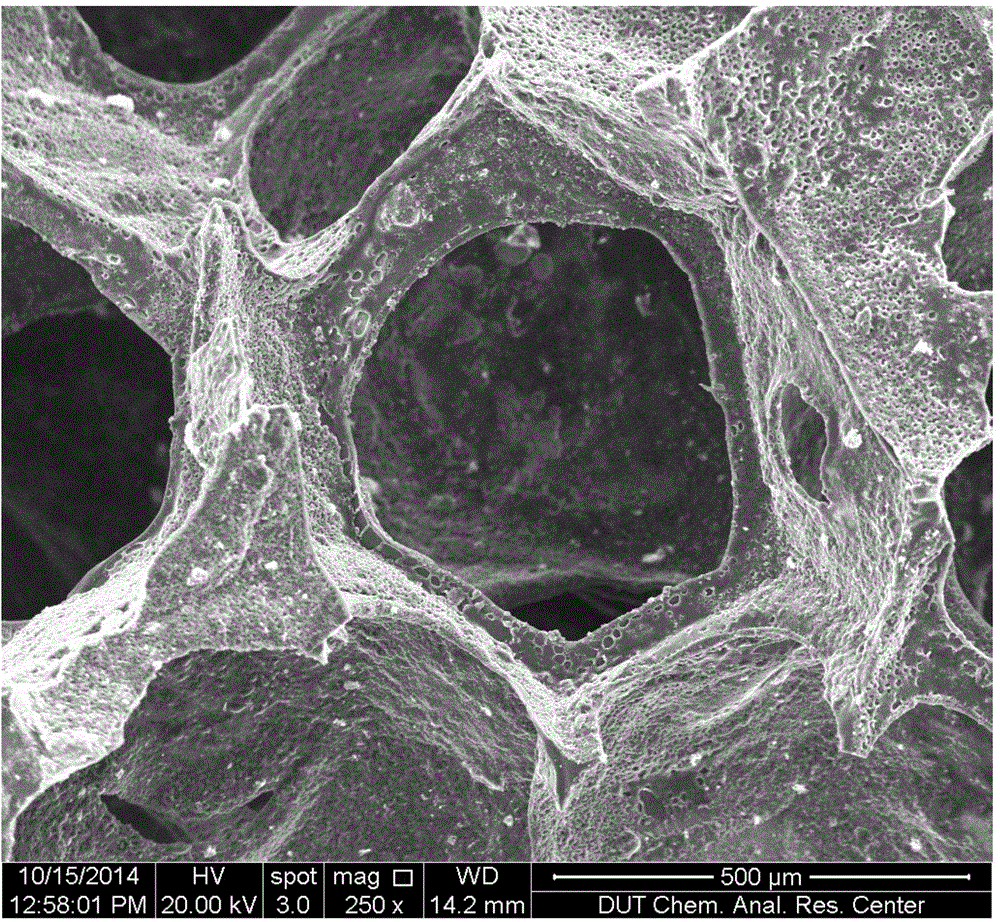

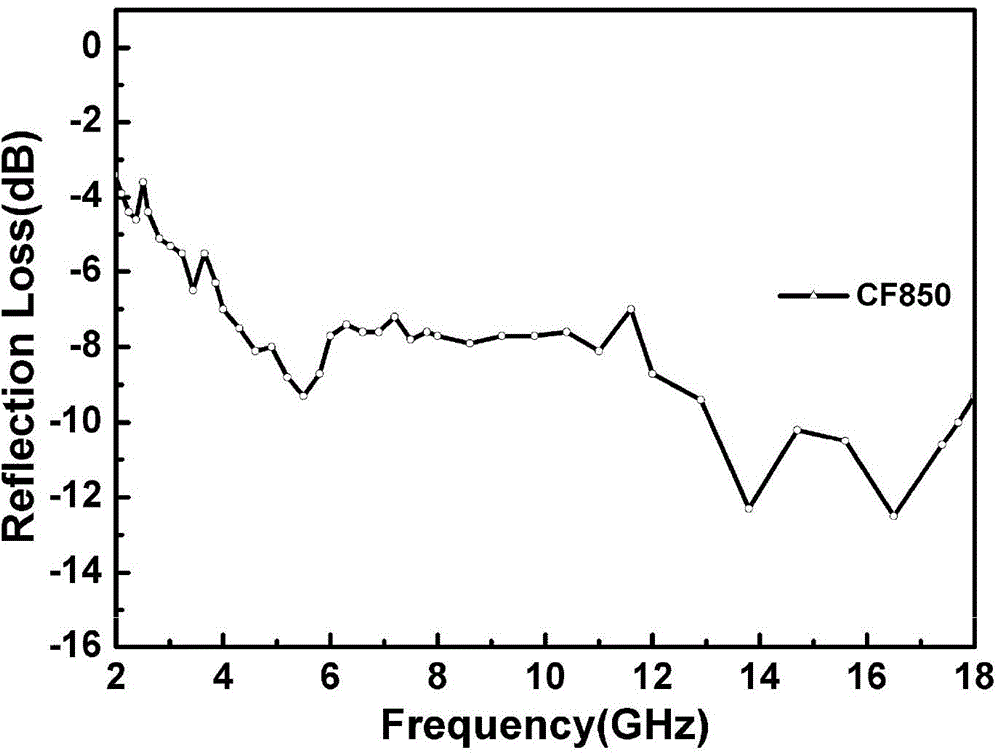

[0018] Weigh 100g of coal liquefaction residue, 10g of nickel nitrate, 4g of iodine and 300g of tetrahydrofuran in a beaker, and stir for 10 minutes; soak a 30cm×15cm×10cm polyurethane foam in the solution and take it out, use filter paper to repeatedly squeeze, and then squeeze The polyurethane foam with the solution was dried in the air for 15 minutes; the dried polyurethane foam was placed in a muffle furnace for oxidative curing, the temperature was raised from room temperature to 300 °C at a rate of 1 °C / min, kept at a constant temperature for 60 min, and cooled naturally to room temperature; in addition, during the oxidation curing process, it is necessary to add high-temperature resistant and low-density thin plates on both sides of the polyurethane foam for fixing to prevent the polyurethane foam from bending; then cut the polyurethane foam after oxidation and curing into 15cm×22cm Carry out heating and carbonization treatment in a muffle furnace. Under the protection o...

Embodiment 2

[0020]Weigh 80g of coal liquefaction residue, 5g of ferric acetate, 2g of bromine and 250g of tetrahydrofuran in a beaker, and stir for 15 minutes; soak 30cm×15cm×0.8cm polyurethane foam in the solution and take it out, use filter paper to repeatedly squeeze, and then squeeze Finally, the polyurethane foam with the solution was dried in the air for 25 minutes; the dried polyurethane foam was placed in a muffle furnace for oxidative curing. Cool to room temperature; in addition, during the oxidation curing process, it is necessary to add high-temperature resistant and low-density thin plates on both sides of the polyurethane foam for fixing to prevent the polyurethane foam from bending; then cut the polyurethane foam after oxidation and curing into 10cm×20cm Carry out heating and carbonization treatment in a muffle furnace. Under the protection of argon, the temperature is raised from room temperature to 800 °C at a heating rate of 1 °C / min, kept at a constant temperature for 30...

Embodiment 3

[0022] Weigh 10g of coal liquefaction residue, 0.25g of zinc nitrate, 1g of iodine, and 50g of tetrahydrofuran in a beaker, and stir for 5 minutes; soak 3cm×15cm×1.5cm polyurethane foam in the solution and take it out. After pressing, the polyurethane foam with the solution was dried in the air for 10 minutes; the dried polyurethane foam was placed in a muffle furnace for oxidative curing, and the temperature was raised from room temperature to 250 °C at a rate of 5.0 °C / min, and kept at a constant temperature for 30 min. Naturally cool to room temperature; in addition, during the oxidation curing process, it is necessary to add high-temperature resistant, low-density thin plates on both sides of the polyurethane foam for fixing to prevent the polyurethane foam from bending; then cut the polyurethane foam after oxidation and curing into 15cm×22cm Put it in a muffle furnace for heating and carbonization treatment. Under the protection of argon, the temperature is raised from roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com