System for performing power generation by utilizing liquid thermoelectric effect

A technology of thermoelectric power generation and liquid, which is applied in the direction of generators, generators/motors, and electrical components that convert kinetic energy into electrical energy. It can solve the problems of no electrical energy output and the inability to form net charges, and achieve improved efficiency, simple structure, and reduced The effect of flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

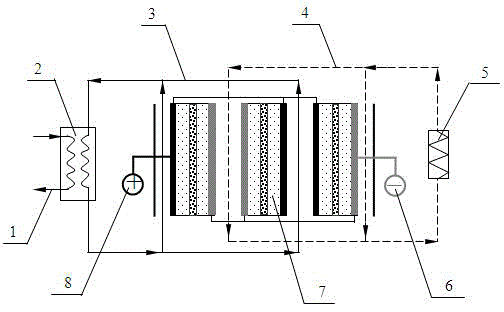

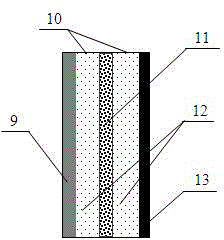

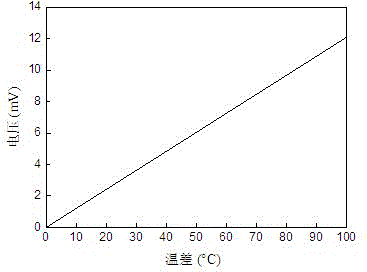

[0034] see figure 1 , using a single liquid thermoelectric power generation unit, the ion exchange membrane described in the power generation unit is an alumina nanoporous membrane with a diameter of 25 mm, a pore diameter of 100 nm, a height of 60 μm, and a porosity of about 60%. The negative pole of the power generation unit is a silver electrode, and the power generation unit The positive pole is a silver chloride electrode, and the electrolyte solution is 10 -4 mol / L sodium chloride solution, the working medium of the low-temperature circulation loop is a mixture of ice and water, and the working medium of the high-temperature circulation loop is water. The hot circulating water flows through the positive electrode (silver chloride electrode) side of the power generation unit, and the cold ice water flows through the negative electrode (silver electrode) side of the power generation unit. The structural characteristics of other parts are the same as figure 1 same. Since ...

Embodiment 2

[0036] see figure 1 , using a single liquid thermoelectric power generation unit, the ion exchange membrane described in the power generation unit is an anodized aluminum nanoporous membrane with a diameter of 25mm, a pore diameter of 100nm, a height of 60μm, and a porosity of about 60%. The electrode is a standard silver-chloride Silver electrode pair, electrolyte solution is 10 -2 mol / L potassium chloride solution, the working fluid of the low-temperature circulation loop is ice-water mixture, and the working medium of the high-temperature circulation loop is hot water at 60 ° C. The structural characteristics of other parts are the same as figure 1 same. After the system works stably, it is detected that its output current is 27.8μA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com