Solvothermal synthetic method of TiO2 hollow-structure submicron spheres

A technology of hollow structure and synthesis method, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

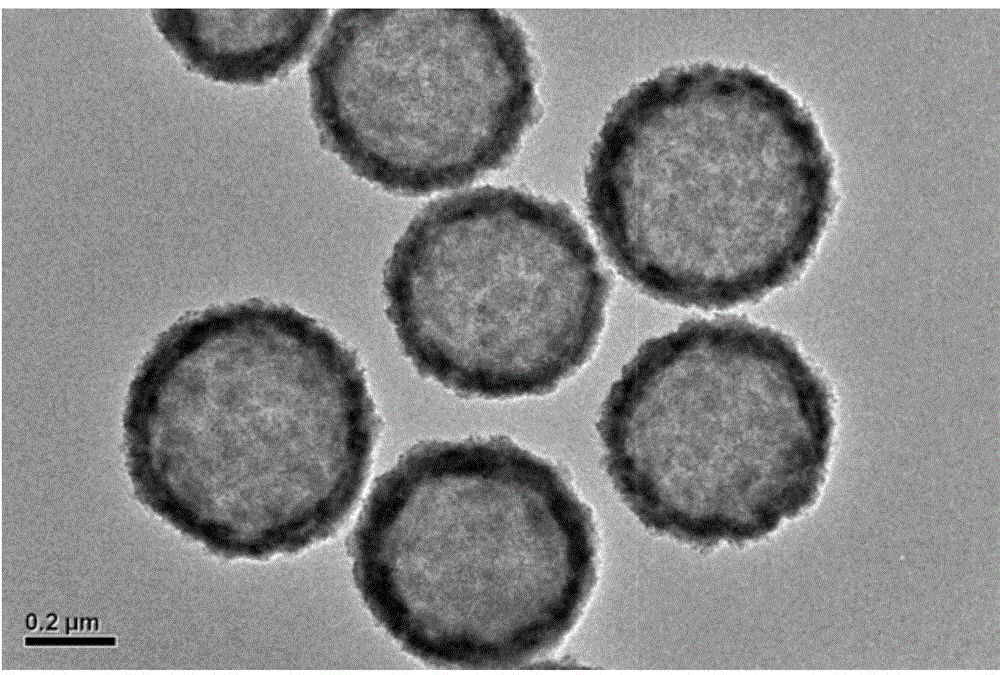

[0019] Mix acetylacetone and ethylene glycol dimethyl ether at a volume ratio of 1:4 to form a mixed solvent. After stirring evenly, add 2ml of tetra-n-butyl titanate (TBT), then fully stir and transfer the mixed solution to the reaction kettle, 200 °C for 12 hours. After natural cooling, TiO was obtained by centrifugation, washing and drying. 2 Hollow structure submicron spheres ( figure 1 ), the microsphere diameter is 450-550 nm.

Embodiment 2

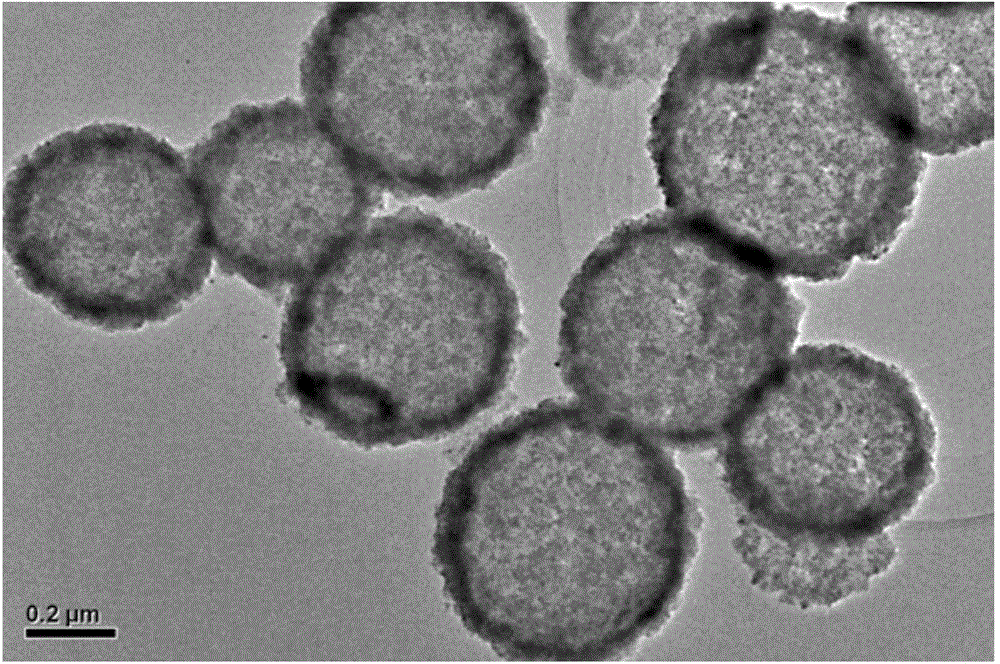

[0021] Mix acetylacetone and ethylene glycol dimethyl ether at a volume ratio of 1:4 to form a mixed solvent. After stirring evenly, add 2ml of tetra-n-butyl titanate (TBT), then fully stir and transfer the mixed solution to the reaction kettle, 200 °C for 24 hours. After natural cooling, TiO was obtained by centrifugation, washing and drying. 2 Hollow structure submicron spheres ( figure 2 ), the diameter of microspheres is 500-600 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com