Multi-layer three-dimensional fiber composite GRC hollow insulation board and preparation method thereof

A fiber composite and thermal insulation board technology, which is applied in covering/lining, construction, building construction, etc., can solve the problems of substandard performance such as durability and fire prevention, increased structural load due to its own weight, and low strength that affects safety in use, etc., to achieve The effects of overcoming poor bonding force, improving molding efficiency, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

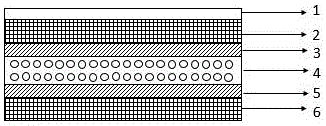

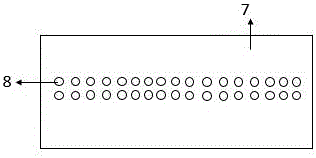

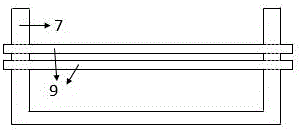

Method used

Image

Examples

Embodiment example 1

[0059] (1) Open two-thirds of the mold with multiple rows of holes;

[0060] (2) Mix 30kg (30%) of cement, 0.5kg (0.5%) of powdered pigment, 32kg (32%) of sand, 2kg (2%) of ceramic debris, 8kg (8%) of dispersible latex powder, and 0.5 kg of PP fiber kg (0.5%), water reducing agent naphthalenesulfonic acid formaldehyde condensate 1kg (1%), early strength agent sulfonate 0.5kg (0.5%), antifreeze agent calcium chloride 0.5kg (0.5%), water 25kg (25 %), mix and stir evenly to make decorative layer mortar;

[0061] (3) Make the decorative layer mortar in the mold by spraying, let it cure naturally for 10 minutes, and then place the three-dimensional fiber on the decorative surface layer;

[0062] (4) Mix cement 25kg (25%), sand 35kg (35%), redispersible latex powder 8kg (8%), alkali-resistant glass fiber 4kg (4%), carbon fiber 1kg (1%), water reducer naphthalene Sulfonic acid formaldehyde condensate 1kg (1%), early strength agent sulfonate 0.5kg (0.5%), antifreeze agent calcium chlo...

Embodiment example 2

[0071] (1) Open two-thirds of the mold with multiple rows of holes;

[0072] (2) Mix 50kg (50%) of cement, 1kg (1%) of liquid pigment, 18kg (18%) of fine stones, 2kg (2%) of glass debris, 5kg (5%) of polypropylene emulsion, and 1kg (1% of PVA fiber) ), water reducing agent sulfonated melamine formaldehyde condensate 1.5kg (1.5%), early strength agent nitrite 0.5kg (0.5%), antifreeze agent potassium carbonate 0.5kg (0.5%), retarder wood calcium 0.5kg ( 0.5%), water 20kg (20%) mixed, and stirred evenly to make decorative layer mortar;

[0073] (3) Make the decorative layer mortar in the mold by brushing, let it cure naturally for 60 minutes, and then place the three-dimensional fiber on the decorative surface layer;

[0074] (4) Put 50kg (50%) of cement, 38.5kg (38.5%) of sand, 3kg (3%) of polypropylene emulsion, 1kg (1%) of alkali-resistant glass fiber, 0.5kg (0.5%) of fly ash, and 7kg of water ( 7%), mix and stir evenly to make structural layer mortar;

[0075] (5) Quantita...

Embodiment example 3

[0083] (1) Open two-thirds of the mold with multiple rows of holes;

[0084] (2) Put 25kg (25%) of cement, 5kg (5%) of powdered pigment, 55kg (55%) of sand, 5kg (5%) of metal debris, 2kg (2%) of styrene-acrylic emulsion, and water-reducing agent polycarboxylate Mix 0.5kg (0.5%) of acid superplasticizer, 0.5kg (0.5%) of triethanolamine (0.5%) of early strength agent, 0.5kg (0.5%) of antifreeze sodium nitrite, and 6.5kg (6.5%) of water, and make decoration after stirring evenly layer of mortar;

[0085] (3) Make the decorative layer mortar in the mould, using laying and vibrating method, and let it cure naturally for 10-60 minutes, and then place the three-dimensional fiber on the decorative surface layer;

[0086] (4) Mix cement 40kg (40%), sand 20kg (20%), styrene-acrylic emulsion 5kg (5%), alkali-resistant glass fiber 3kg (3%), PVA fiber 1kg (1%), water reducer polycarboxylate Acid superplasticizer 0.5kg (0.5%), early strength agent triethanolamine 0.3kg (0.3%), antifreeze ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com