Modified PEEK-based self-lubricating three-layer composite material and forming method thereof

A composite material and molding method technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of overall performance decline, high melt viscosity, poor mutual bonding force, etc., to improve the overall performance, Improved consistency and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A modified PEEK-based self-lubricating three-layer composite material and a molding method thereof, comprising the following steps:

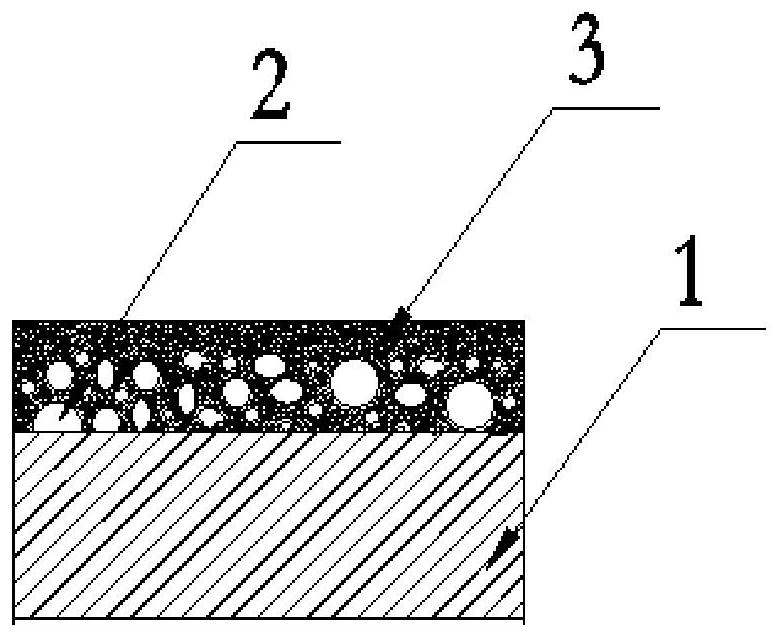

[0053] (1) Prepare the substrate: Sinter the spherical porous copper powder layer 2 on the metal substrate 1 to prepare a bimetallic spherical powder board.

[0054] (2) Preparation of plastic clay:

[0055] a. Ingredients: Measure PEEK resin, additives, and plastic clay forming agent as raw materials for later use.

[0056] Wherein, the particle size of the PEEK resin is 200 mesh. The additive is powder additive, the lubricant is graphite, and the reinforcing agent is PPTA. The plastic clay forming agent is polytetrafluoroethylene emulsion, and the solid content of the polytetrafluoroethylene emulsion is 60±2%.

[0057] b. Powder mixing: Mix and stir the above-mentioned PEEK resin, graphite, and PPTA for 3 times at a stirring speed of 200r / min, and each stirring time is 5 seconds, so that it becomes a uniformly mixed powder mixture. ...

Embodiment 2

[0069] A modified PEEK-based self-lubricating three-layer composite material and a molding method thereof, comprising the following steps:

[0070] (1) Prepare the substrate: Sinter the spherical porous copper powder layer 2 on the metal substrate 1 to prepare a bimetallic spherical powder board.

[0071] (2) Preparation of plastic clay:

[0072] a. Ingredients: Measure PEEK resin, additives, and plastic clay forming agent as raw materials for later use.

[0073] Wherein, the particle size of the PEEK resin is 500 mesh. The additives include powder additives and liquid additives, molybdenum disulfide is selected as the powder additive for the lubricant, and PAI dispersion liquid with a concentration of 20% is selected as the liquid additive for the reinforcing agent. The plastic clay forming agent is polytetrafluoroethylene emulsion, and the solid content of the polytetrafluoroethylene emulsion is 60±2%.

[0074] b. Powder mixing: Mix and stir the above-mentioned PEEK resin...

Embodiment 3

[0086] A modified PEEK-based self-lubricating three-layer composite material and a molding method thereof, comprising the following steps:

[0087] (1) Prepare the substrate: Sinter the spherical porous copper powder layer 2 on the metal substrate 1 to prepare a bimetallic spherical powder board.

[0088] (2) Preparation of plastic clay:

[0089] a. Ingredients: Measure PEEK resin, additives, and plastic clay forming agent as raw materials for later use.

[0090] Wherein, the particle size of the PEEK resin is 300 mesh. The additive is powder additive, the lubricant is polytetrafluoroethylene powder, and the reinforcing agent is PPS. The plastic clay forming agent is polytetrafluoroethylene emulsion, and the solid content of the polytetrafluoroethylene emulsion is 60±2%.

[0091] b. Powder mixing: Mix and stir the above-mentioned PEEK resin, graphite, and PPS 4 times at a stirring speed of 300r / min, and each stirring time is 7 seconds, so that it becomes a uniformly mixed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com