Preparation method of organic optoelectronic device cathode interface layer based on conjugated polyelectrolyte and application thereof

A technology of conjugated polyelectrolyte and cathode interface layer, which is applied in the fields of electrical solid device, semiconductor/solid state device manufacturing, electrical components, etc., can solve the problems of low efficiency of organic solar cell devices, unsuitable cathode interface layer, etc. The assembly process, experimental conditions are easy to control, and the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

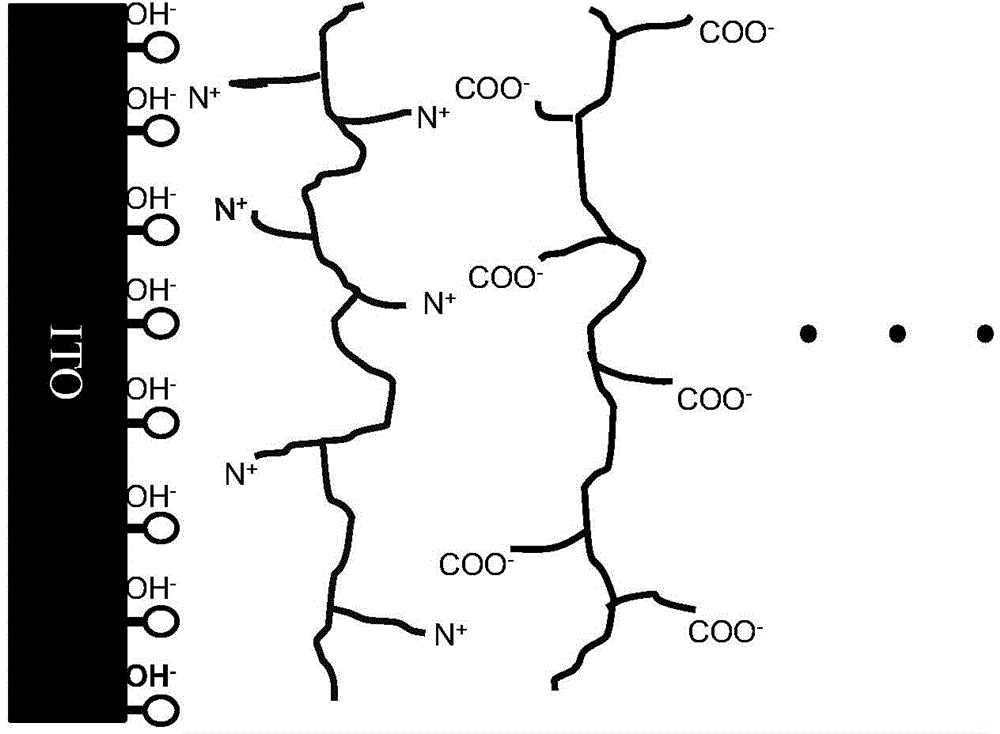

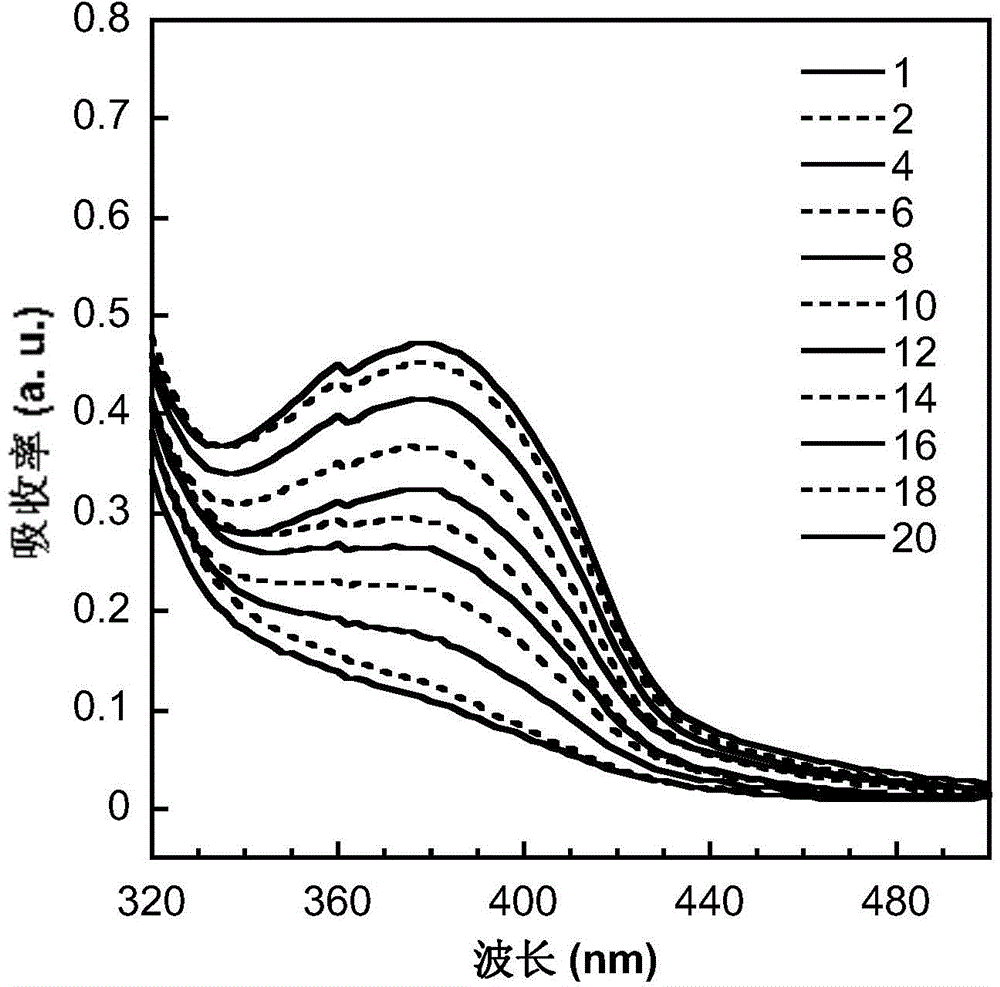

[0037] The preparation process of the cathode interface layer of the organic photoelectric device based on the conjugated polyelectrolyte in this embodiment is as follows:

[0038] Synthesis of cationic conjugated polyelectrolyte PFNBr: 0.5 mmol 2,7-dibromo-9,9-bis(3'-(N,N-dimethylamino)propyl)fluorene, 0.5 mmol 2,7-bis(4, 4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)-9,9-dioctylfluorene, 10mg catalyst Pd(PPh 3 ) 4 , three drops of methyl trioctyl ammonium chloride was added to 3mL of toluene and 2mL of 2mol / L Na 2 CO 3 in the mixed solution. The mixture was refluxed for 3 days under the protection of argon. After the reaction dropped to room temperature, the reaction liquid was settled with 200 mL of methanol, and the obtained precipitate was filtered with acetone for 24 hours to remove the monomer and the catalyst. Then 100 mg of the product was dissolved in 40 mL of tetrahydrofuran, 2 g of bromoethane and 10 mL of DMSO were added, and the reaction was carried out at 50° C...

Embodiment 2

[0051] The preparation process of the cathode interface layer of the organic photoelectric device based on the conjugated polyelectrolyte in this embodiment is as follows:

[0052] Synthesis of cationic conjugated polyelectrolyte PFNI: 0.5 mmol 2,7-dibromo-9,9-bis(3'-(N,N-dimethylamino)propyl)fluorene, 0.5 mmol 2,7-bis(4, 4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)-9,9-dioctylfluorene, 10mg catalyst Pd(PPh 3 ) 4 , three drops of methyl trioctyl ammonium chloride was added to 3mL toluene and 2Ml 2mol / L Na 2 CO 3 in the mixed solution. The mixture was refluxed for 3 days under the protection of argon. After the reaction dropped to room temperature, the reaction liquid was settled with 200 mL of methanol, and the obtained precipitate was filtered with acetone for 24 hours to remove the monomer and the catalyst. Then 100 mg of the product was dissolved in 40 mL of tetrahydrofuran, 2.6 g of iodomethane and 10 mL of DMSO were added, and the reaction was carried out at 50° C. for...

Embodiment 3

[0063] The preparation process of the cathode interface layer of the organic photoelectric device based on the conjugated polyelectrolyte in this embodiment is as follows:

[0064] Synthesis of cationic conjugated polyelectrolyte PCNBr: 0.5mmol 9-(N,N-dimethyl-3'-amino-propyl)-2,7-dibromocarbazole, 0.5mmol 2,7-bis(4,4 ,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)-N-9-heptadecylcarbazole, 12mg catalyst Pd(PPh 3 ) 4 , three drops of methyl trioctylammonium chloride were added to 10mL of toluene and 2mL of 2mol / L K 2 CO 3 in the mixed solution. The mixture was refluxed for 24 hours under the protection of argon. After the reaction dropped to room temperature, the reaction solution was settled with 250 mL of methanol, and the obtained precipitate was filtered with toluene solvent, then settled with methanol, washed with acetone, and dried. 100 mg of the product was dissolved in 40 mL of tetrahydrofuran, 2 g of bromoethane and 10 mL of DMSO were added, and the reaction was carried...

PUM

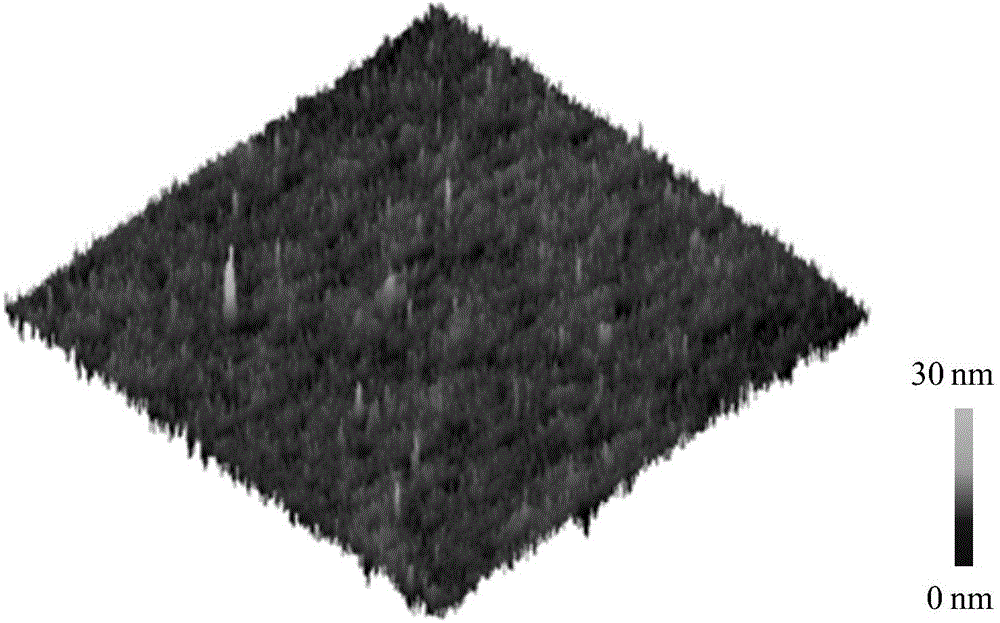

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com