Ship exhaust gas mixed type desulfurization device and working method thereof

A desulfurization device, exhaust gas desulfurization technology, applied in the direction of separation methods, steam engine devices, chemical instruments and methods, etc., can solve the problems of unable to meet the heating heat of the main engine of the ship, corrosion of heat exchangers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

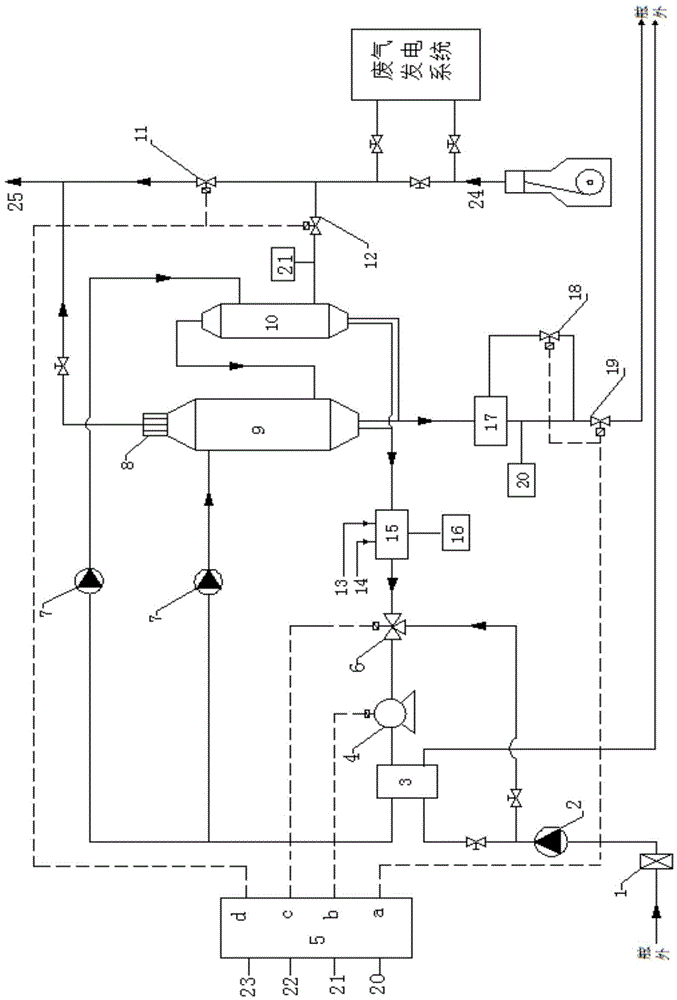

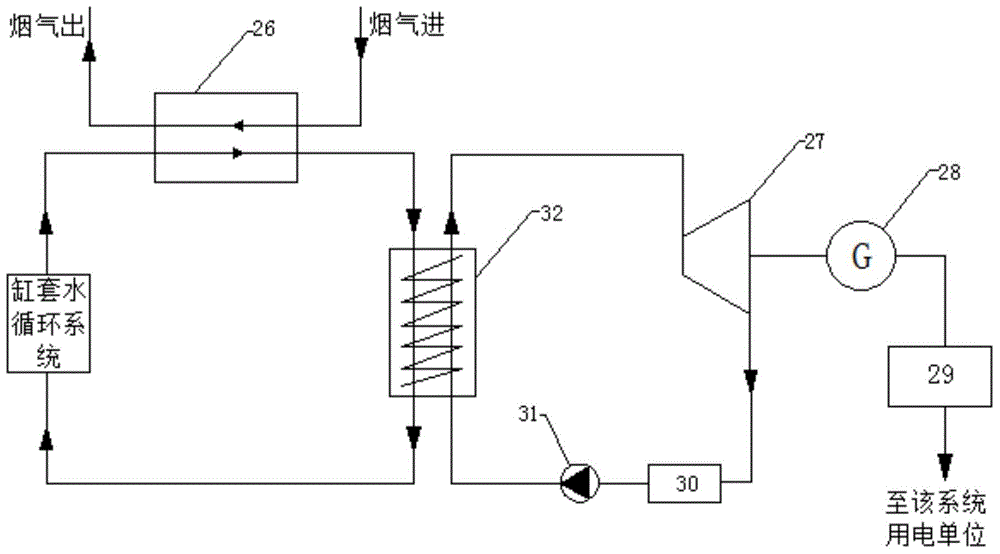

[0030]The present invention will be further described below in conjunction with the accompanying drawings. like Figure 1-2 As shown, a ship exhaust gas hybrid desulfurization device includes an exhaust gas power generation system, an exhaust gas desulfurization system, an exhaust gas discharge system, and an automatic monitoring and control system; the exhaust gas power generation system includes a jacket water heat exchanger 26, an evaporator 32, Expander 27, condenser 30, working medium pump 31, generator 28 and power storage device 29; the jacket water heat exchanger 26 is provided with a flue gas inlet and a flue gas outlet; the jacket water exchanger The left end of the heater 26 is connected to the outlet of the jacket water circulation system, and the right end is connected to the high-temperature side inlet of the evaporator 32. The high-temperature side outlet of the evaporator 32 is connected to the jacket water circulation system inlet to form a high-temperature si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com