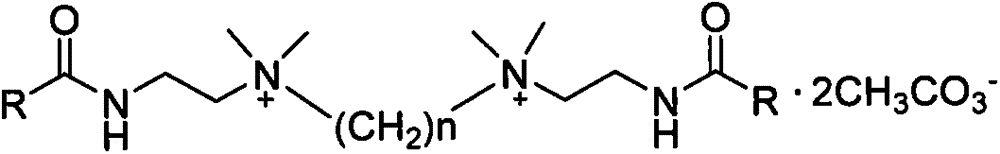

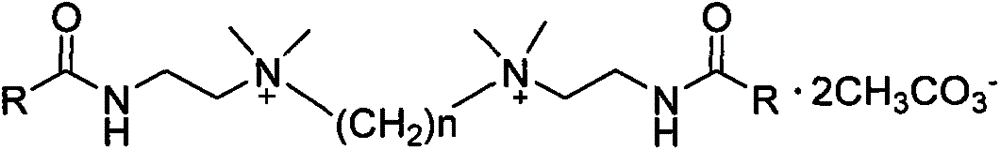

Preparation method of quaternary ammonium salt Gemini surfactant containing alkyl amide ethyl

A surfactant and alkyl amide technology, which is applied in the field of organic compound synthesis, can solve the problems of product residue, unfavorable environmental protection, single counter ion, etc., and achieve the effect that the product surface activity does not pollute the environment and the product surface activity is excellent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

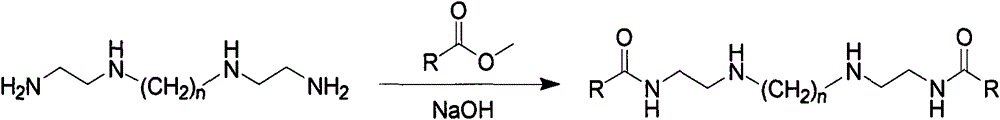

[0016] (1) Preparation of N,N'-bis(2-laurylamide ethyl)-ethylenediamine

[0017] Add 0.1mol triethylenetetramine, 0.2mol methyl laurate, 0.005mol sodium hydroxide and 30mL toluene into a 250mL round bottom flask, stir and heat to 135℃, react at a constant temperature for 20h, and remove the solvent by rotary evaporation. The volume ratio is Recrystallize 1:1 ether and absolute ethanol to obtain N,N'-bis(2-laurylamide ethyl)-ethylenediamine.

[0018] (2) Preparation of N,N'-dimethyl-bis(2-laurylamide ethyl)-ethylenediamine

[0019] Add 0.1mol N,N'-bis(2-laurylamide ethyl)-ethylenediamine and 30mL isopropanol into a 250mL round bottom flask, slowly add 0.5mol formic acid dropwise while stirring, and then slowly dropwise add 0.4mol formaldehyde The aqueous solution was heated to 98°C and reacted at a constant temperature for 20 hours, and then 5% NaOH solution was added dropwise to adjust the pH to 10-12. A white solid was precipitated, filtered and dried to obtain N,N'-dimethyl-bis( ...

Embodiment 2

[0023] (1) Preparation of N,N'-bis(2-myristylamide ethyl)-propanediamine

[0024] Add 0.1mol N,N′-bis(2-aminoethyl)-1,3-propanediamine, 0.22mol methyl myristate, 0.005mol sodium hydroxide and 30mL toluene into a 250mL round bottom flask, and react at a constant temperature After 20 hours, the solvent was removed by rotary evaporation, and recrystallized with ether and absolute ethanol in a volume ratio of 1:1 to obtain N,N'-bis(2-myristylamide ethyl)-propylene diamine.

[0025] (2) Preparation of N,N'-dimethyl-bis(2-myristylamide ethyl)-propanediamine

[0026] Add 0.1mol N,N'-bis(2-myristylamide ethyl)-propanediamine and 35mL isopropanol to a 250mL round bottom flask, slowly add 0.5mol formic acid dropwise while stirring, and then slowly dropwise add 0.4mol The aqueous formaldehyde solution was heated to 98°C and reacted at a constant temperature for 20 hours, and then 5% NaOH solution was added dropwise to adjust the pH value to 10-12. A white solid was precipitated, filtered and d...

Embodiment 3

[0030] (1) Preparation of N,N'-bis-(2-palmitylamide ethyl)-ethylenediamine

[0031] Add 0.1mol triethylenetetramine, 0.2mol methyl palmitate, 0.005mol sodium hydroxide and 40mL toluene into a 250mL round bottom flask, stir and heat to 135℃, react at a constant temperature for 20h, and remove the solvent by rotary evaporation. The volume ratio is 1:1 ether and absolute ethanol are recrystallized to obtain N,N'-bis(2-palmitylamide ethyl)-ethylenediamine.

[0032] (2) Preparation of N,N'-dimethyl-bis(2-palmitylamide ethyl)-ethylenediamine

[0033] Add 0.1mol N,N'-bis(2-palmitylamideethyl)-ethylenediamine and 40mL isopropanol to a 250mL round bottom flask, slowly add 0.5mol formic acid dropwise while stirring, and then slowly dropwise add 0.4mol formaldehyde The aqueous solution was heated to 98°C and reacted at a constant temperature for 20 hours, and then 5% NaOH solution was added dropwise to adjust the pH to 10-12. A white solid was precipitated, filtered and dried to obtain N,N'-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com