Wastewater advanced treatment equipment and method for catalytic ozonation membrane reactor

A membrane reactor and advanced treatment technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult recovery of ozone catalyst and low efficiency of ozone aeration mass transfer. , to achieve the effect of advanced treatment, improved ozone oxidation capacity and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] Taking the secondary biochemical process external discharge of saline waste water of a refining and chemical company as the test object, the example of applying the present invention for advanced treatment further illustrates the present invention.

[0042] The water quality of the wastewater discharged by the enterprise after the secondary biochemical treatment process is: chemical oxygen demand 80-120mg / L, pH 6-9, ammonia nitrogen 7-12mg / L, conductivity 3-4mS / cm.

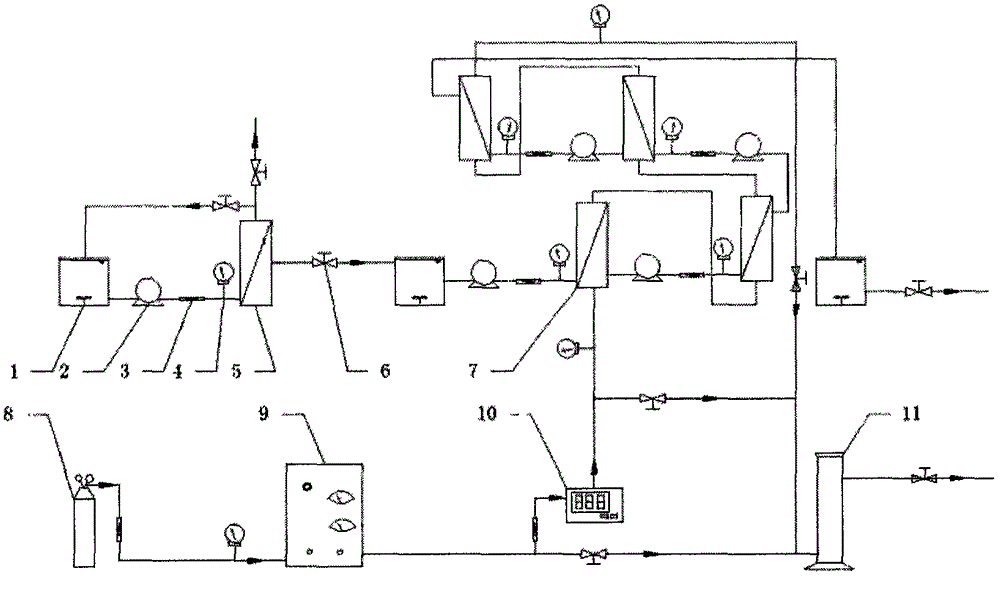

[0043] like figure 1 As shown in the technological process, the above-mentioned waste water to be treated is 1m 3 The / h flow is introduced into the raw water tank, pressurized to 2 atm by the pump 2, and then enters the pre-filter 5 filled with quartz sand. The chemical oxygen demand of the product water is 75-110mg / L.

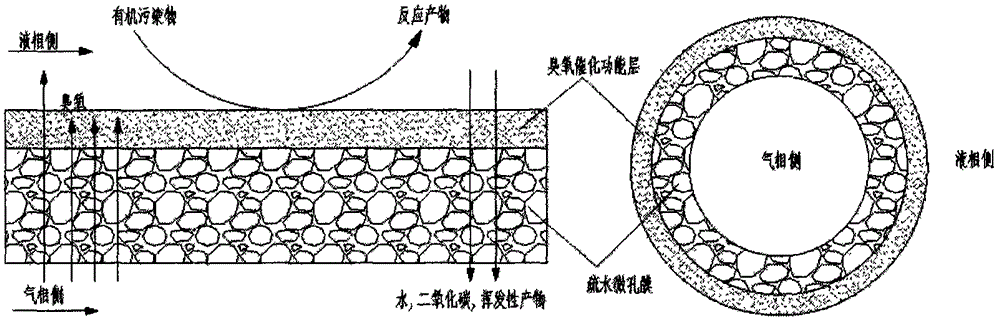

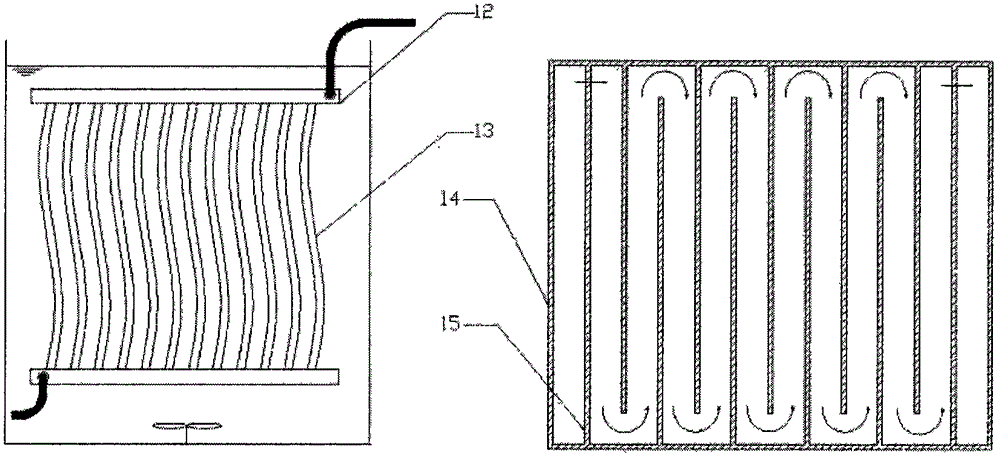

[0044] The above-mentioned produced water is introduced into one side of catalytic ozone membrane reactor 7, and for each membrane reactor, the waste water flow rate is 125L / h. There are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com