Copper indium gallium selenide film solar battery and preparation method thereof

A technology of solar cells and copper indium gallium selenide, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high cost, poor uniformity in large areas, and high cost, so as to reduce preparation costs, improve safety, and accelerate industrial applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

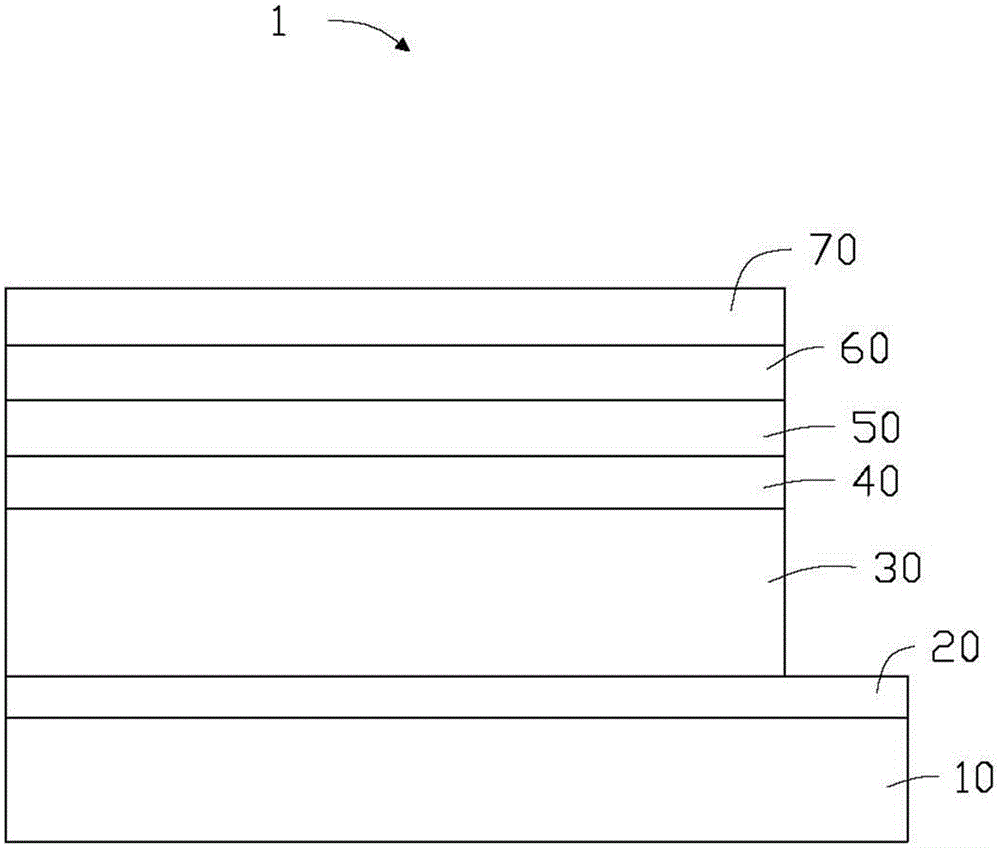

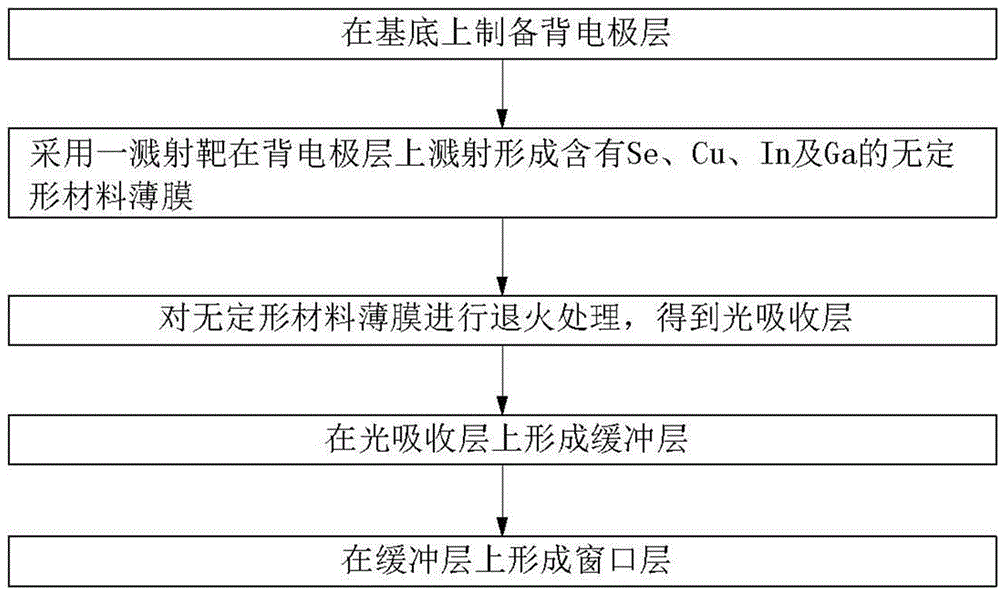

[0042] see figure 2 , the embodiment of the present invention provides a method for preparing the copper indium gallium selenide thin film solar cell 1, comprising the following steps:

[0043] 1) preparing the back electrode layer 20 on the substrate 10;

[0044] 2) using a sputtering target to sputter on the back electrode layer 20 to form an amorphous material film containing Se, Cu, In and Ga; and

[0045] 3) Annealing the amorphous material film, the annealing atmosphere is at least one of vacuum, rare gas (preferably argon) and nitrogen, the annealing temperature is 300 ° C ~ 600 ° C, and the heating rate is 1°C / min~100°C / min, the annealing time is 0.1 hour~3 hours, to obtain the light absorbing layer 30;

[0046] 4) forming a buffer layer 40 on the light absorbing layer 30; and

[0047] 5) Forming the window layer 50 on the buffer layer 40 .

[0048] Specifically, in the step 1), the back electrode layer 20 can be prepared on the surface of the substrate 10 by phys...

Embodiment 1

[0079] Embodiment 1: sputtering target and preparation method thereof

Embodiment 1-1

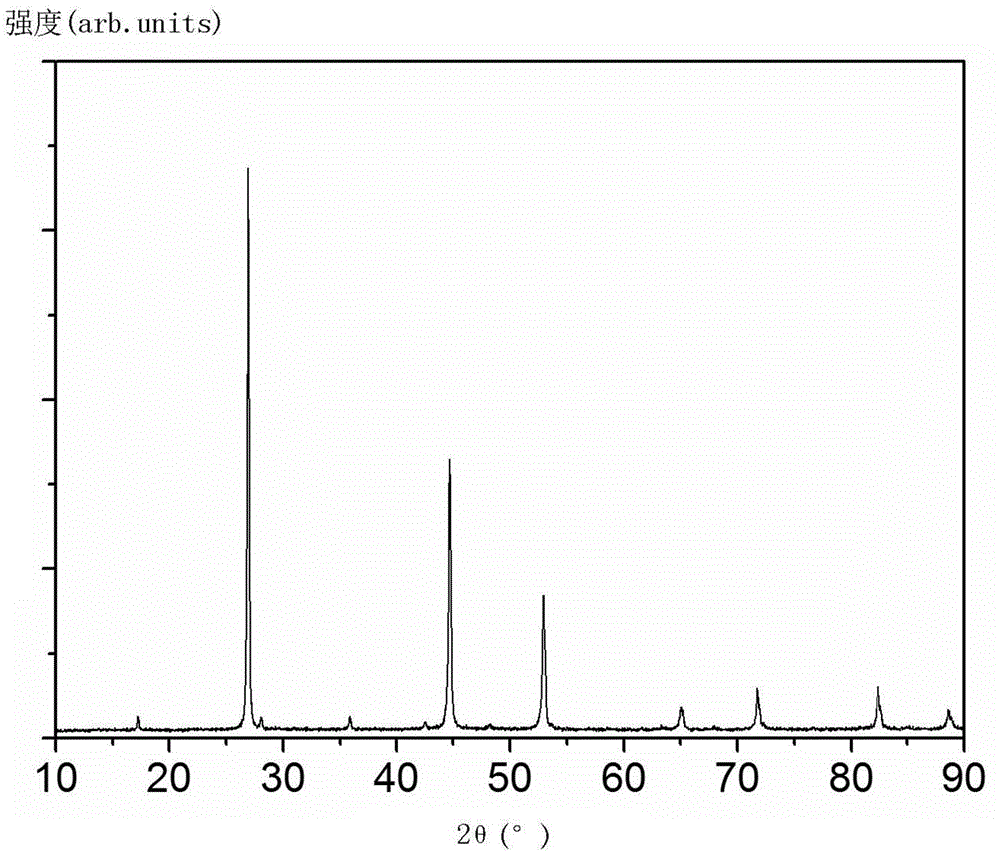

[0081] Weigh 290 g of CIGS powder, 50 g of elemental Se powder, 50 g of elemental Se powder, and 1800 g, put into a ball mill jar and mix. The ball milling medium is absolute ethanol, the ball milling speed is 300 rpm, and the ball milling time is 8 h. After ball milling, dry to obtain mixed powder. The target was prepared by atmospheric pressure sintering, the mixed powder was put into a press, and pressed in a mold with a pressure of 100 MPa and a holding time of 15 min. After demoulding, it was put into a sintering furnace, and sintered in a high-purity argon atmosphere with a sintering temperature of 600 oC, a heating rate of 10 oC / min, and a sintering time of 5 h. After sintering, the furnace was cooled to room temperature for sampling. The target has no defects such as cracks and cracks, the compactness rate reaches 95.7%, and the molar percentage of Se in the target is 55%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com