Preparation method of high-whiteness light-resistance rutile type titanium dioxide substrate

A titanium dioxide and rutile-type technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of increasing the production cost of titanium dioxide, not being able to improve light resistance, and limited commercial value, so as to eliminate the problem of yellow phase and improve whiteness , the effective effect of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

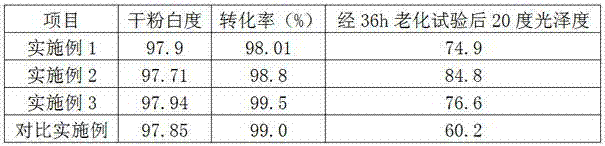

Examples

preparation example Construction

[0030] The preparation method of the high whiteness and light fastness rutile titanium dioxide base material of the present invention comprises the following steps:

[0031] (1) Preparation of metatitanic acid: acidolysis of ilmenite and sulfuric acid to obtain titanyl sulfate, which is then precipitated, crystallized, and hydrolyzed to generate metatitanic acid;

[0032] (2) One-time water washing of metatitanic acid: Wash metatitanic acid with deionized water at a temperature of 50-80°C to remove metal impurities;

[0033] (3) Preparation of metatitanic acid slurry: add water to the washed metatitanic acid to make a slurry, and the concentration of the slurry is 300-350g / L;

[0034] (4) Bleaching metatitanic acid slurry: add sulfuric acid to the metatitanic acid slurry to make the sulfuric acid concentration of the slurry 60-90g / L, and add 5wt% calcined rutile titanium dioxide seeds to the slurry at the same time and 0.2wt% Ti 3+ solution, the weight percent metering basis...

Embodiment 1

[0040] (1) Preparation of metatitanic acid slurry: take the washed metatitanic acid, add enough deionized water, and prepare the slurry with a total mass of 2000g, TiO 2 Content is 25% metatitanic acid slurry;

[0041] (2) Bleaching of metatitanic acid: Slowly add 90g of concentrated sulfuric acid and stir, then heat the system to 60°C in a water bath;

[0042] (3) Add 5.0% calcined seed crystals, that is, add 238.1g calcined seed crystals with a mass fraction of 10.5%, stir for 30min and add 14g Ti with a mass fraction of 5.15% 3+ solution, then continue to stir for 90min;

[0043] (4) Wash the bleached metatitanic acid with deionized water at a temperature of 50-80°C, and then make a pulp to make a 300g / L metatitanic acid slurry and conduct quantitative analysis on the slurry, and the ferrous ion content is less than 20ppm ;

[0044] (5) 7.80g of KOH with a mass fraction of 17.31% (after adding KOH 2 O mass fraction is 0.27%), 4.20g mass fraction is 23.86% H 3 PO 4 (Af...

Embodiment 2

[0047] (1) Preparation of metatitanic acid slurry: take the washed metatitanic acid, add enough deionized water, and prepare a metatitanic acid slurry with a total mass of 2000g and a TiO2 content of 25%;

[0048] (2) Bleaching of metatitanic acid: Slowly add 90g of concentrated sulfuric acid and stir, then heat the system to 60°C in a water bath;

[0049] (3) Add 5.0% calcined seed crystals, that is, add 238.1g calcined seed crystals with a mass fraction of 10.5%, stir for 30min and add 14g Ti with a mass fraction of 5.15% 3+ solution, then continue to stir for 90min;

[0050] (4) Wash the bleached metatitanic acid with deionized water at a temperature of 50-80°C, and then make a pulp to make a 300g / L metatitanic acid slurry and conduct quantitative analysis on the slurry, and the ferrous ion content is less than 20ppm ;

[0051] (5) 7.80g of KOH with a mass fraction of 17.31% (after adding KOH 2 O mass fraction is 0.27%), 4.20g mass fraction is 23.86% H 3 PO 4 (After ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com