Lead manganate antimonate doped niobium nickel-lead zirconate titanate piezoelectric ceramic

A technology of lead manganese antimonate and lead zirconate titanate, which is applied in the field of piezoelectric ceramic materials, can solve the problems of limited material performance parameters and inability to be suitable, and achieve the effect of improving machining performance, piezoelectric coefficient and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

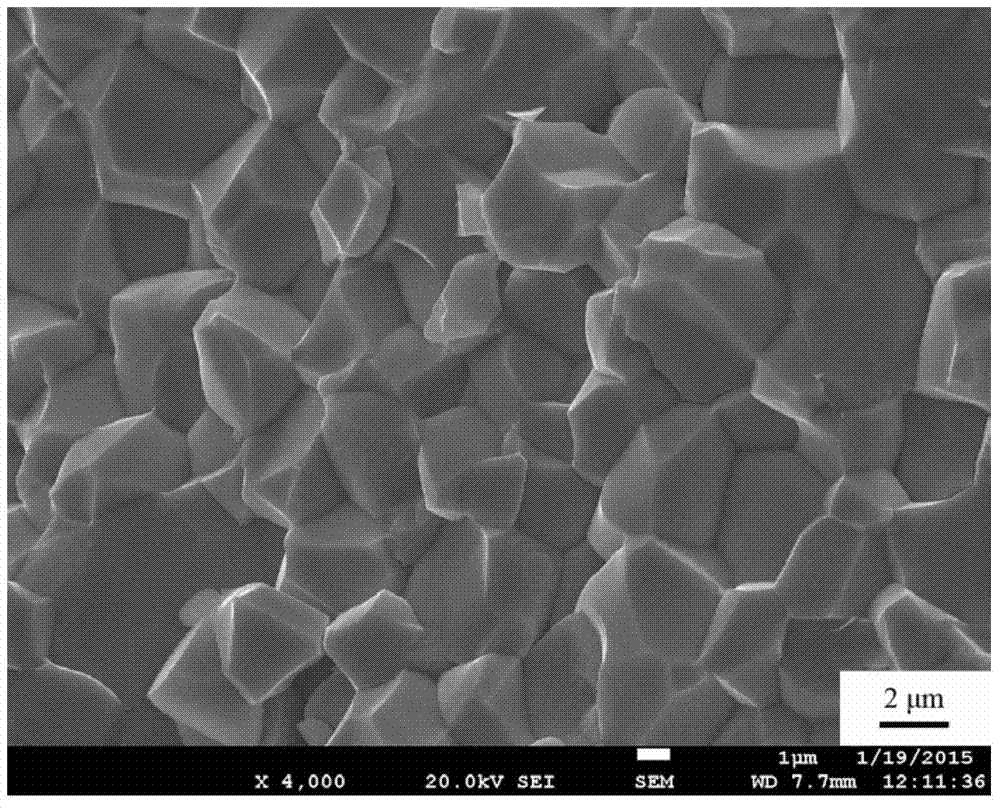

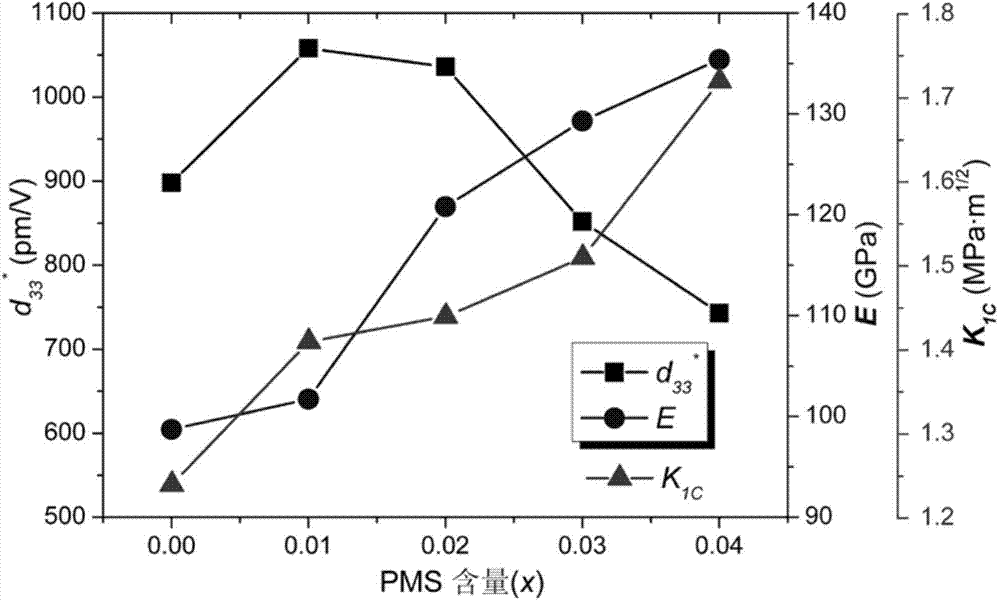

[0025] The present invention analyzes pure grade Pb 3 o 4 , ZrO 2 、TiO 2 , MnO 2 , Sb 2 o 3 , NiO, Nb 2 o 5 As the raw material, according to the chemical formula (1-x)Pb(Ni 1 / 3 Nb 2 / 3 ) 0.5 Zr y Ti 0.5-y o 3 -xPbMn 1 / 3 Sb 2 / 3 o 3 (where y=0.14, x=0.01, Pb 3 o 4Excessive 1.8wt%) weighed the raw materials, put them into a ball mill jar, and used absolute ethanol as the medium. After ball milling for 24 hours, the obtained slurry was put into an oven for drying, passed through a 40-mesh sieve, and pre-fired at 860° C. for 2 hours. The powder obtained by pre-calcination is crushed, ball milled, dried and passed through a 120-mesh sieve, then a certain amount of 3wt% PVA aqueous solution is added to granulate, molded, stayed at 600°C for 2h to debinding, and then sintered at 1250°C for 2h. figure 2 The scanning electron microscope image of the cross-section of the ceramic obtained by sintering shows that the interface is dense, the porosity is low, the grain siz...

Embodiment 2

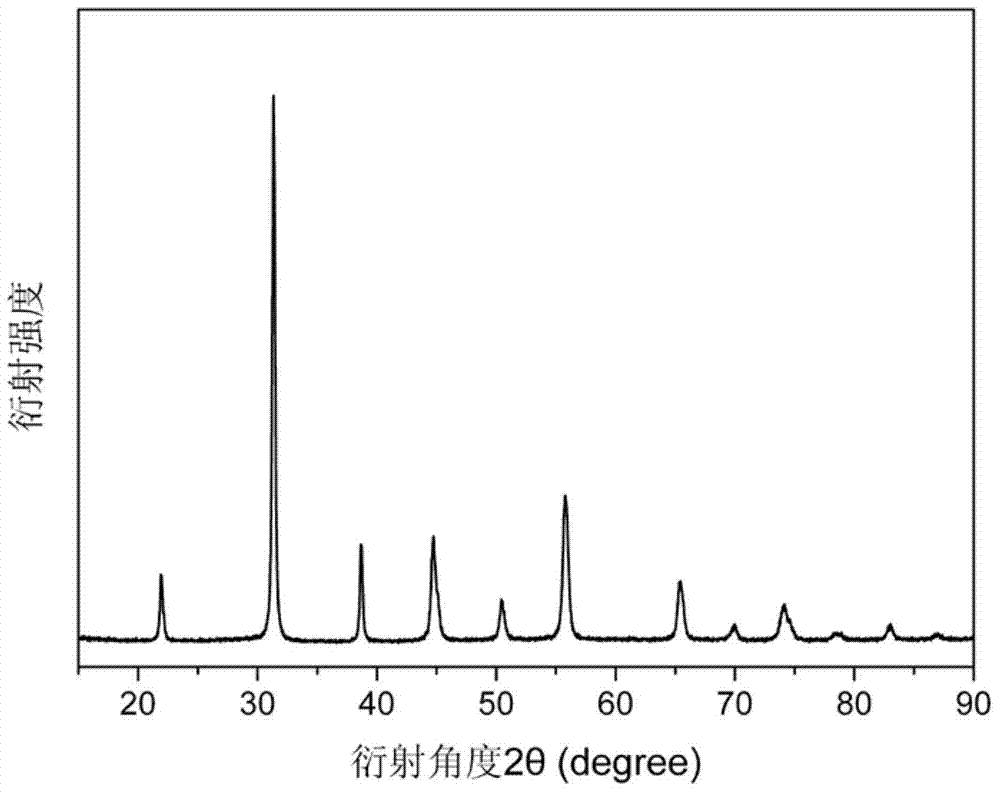

[0027] The present invention analyzes pure grade Pb 3 o 4 , ZrO 2 、TiO 2 , MnO 2 , Sb 2 o 3 , NiO, Nb 2 o 5 As the raw material, according to the chemical formula (1-x)Pb(Ni 1 / 3 Nb 2 / 3 ) 0.5 Zr y Ti 0.5-y o 3 -xPbMn 1 / 3 Sb 2 / 3 o 3 (where y=0.14, x=0.02, Pb 3 o 4 Excessive 1.8wt%) weighed the raw materials, put them into a ball mill jar, and used absolute ethanol as the medium. After ball milling for 24 hours, the obtained slurry was put into an oven for drying, passed through a 40-mesh sieve, and pre-fired at 860° C. for 2 hours. The powder obtained by pre-calcination is crushed, ball milled, dried and passed through a 120-mesh sieve, then a certain amount of 3wt% PVA aqueous solution is added to granulate, molded, stayed at 600°C for 2h to debinding, and then sintered at 1250°C for 2h. figure 1 The XRD pattern of the ceramic obtained by sintering shows that the ceramic shows a pure perovskite structure without pyrochlore impurity phase. Polish the fired pie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com