Treating method for complex copper-molybdenum deposit

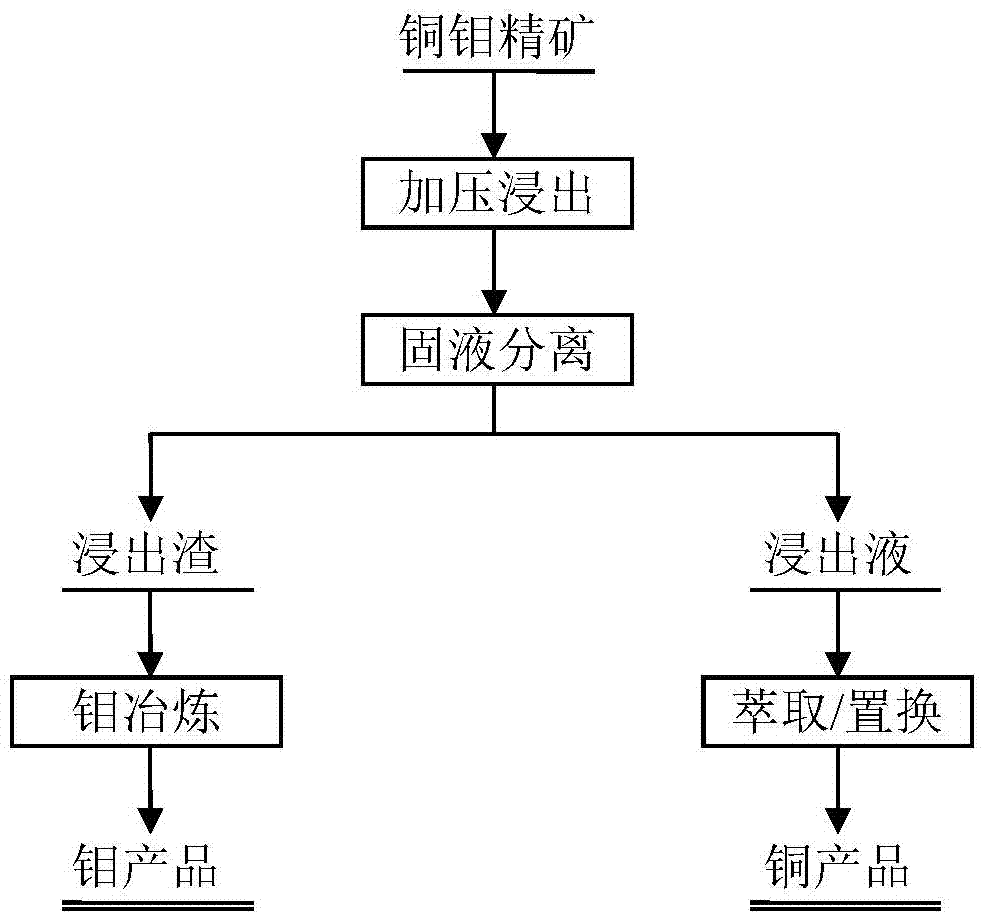

A processing method and technology for copper-molybdenum ore, which are applied in the field of complex copper-molybdenum ore processing, can solve the problems of increased smelting cost, high production cost, large alkali consumption, etc., and can solve the problem of comprehensive recovery, facilitate production and operation, and simplify the process. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Get 100g of copper-molybdenum mixed ore, the main components are 10.63% copper, 30.16% molybdenum, 11.63% iron, and 35.4% sulfur, 90% of which are finely ground to below 300 mesh, add 500ml of dilute sulfuric acid with a concentration of 100g / L for slurrying, Add 0.2g lignin, carry out pressurized oxidation leaching at 150°C, feed oxygen during the process, control the oxygen partial pressure to 5 atm, and react for 2 hours.

[0032] After the reaction is finished, copper, iron, etc. are leached into the solution, the leaching rate of copper, iron, etc. reaches more than 85%, and the slag contains more than 45% molybdenum. Iron powder is added to the filtrate to replace copper, and the purity of the sponge copper is 89.35%. Copper leaching slag is pressurized to oxidize molybdenum at 150-220°C, and the conversion rate of molybdenum can reach more than 98%.

Embodiment 2

[0034] Add 100g of copper-molybdenum ore to 500ml of dilute sulfuric acid with a concentration of 25g / L, add 5g of coal powder, the copper-molybdenum ore contains 8.35% copper and 35.67% molybdenum, control the reaction temperature at 150°C, oxygen partial pressure at 5atm, and leaching time for 3h.

[0035] After the reaction is completed, the copper leaching rate is above 90%, the iron part is precipitated into the leaching slag, and the molybdenum leaching rate is lower than 2%.

[0036] The above solution is extracted to extract copper, and the extraction rate of copper is over 98%. The molybdenum is leached from the leaching slag through pressure oxidation, and the conversion rate of molybdenum is over 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com