Method for preparing ZnO/I-doped ZnO core/shell structure nanowire array

A nanowire array and shell structure technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of unfavorable electron transport at grain boundaries, increase the absorption range, reduce recombination, and improve adsorption volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Prepare ZnO / I doped ZnO core / shell structure nanowire array according to the following steps:

[0026] Step (1): Spin-coat an ethanol solution containing 0.3M ethanolamine and 0.3M zinc acetate on the cleaned FTO conductive glass substrate, dry the film obtained by spin coating, and place it in a 500 o Annealed in the muffle furnace of C for 30 minutes, obtained the conductive glass with ZnO seed layer;

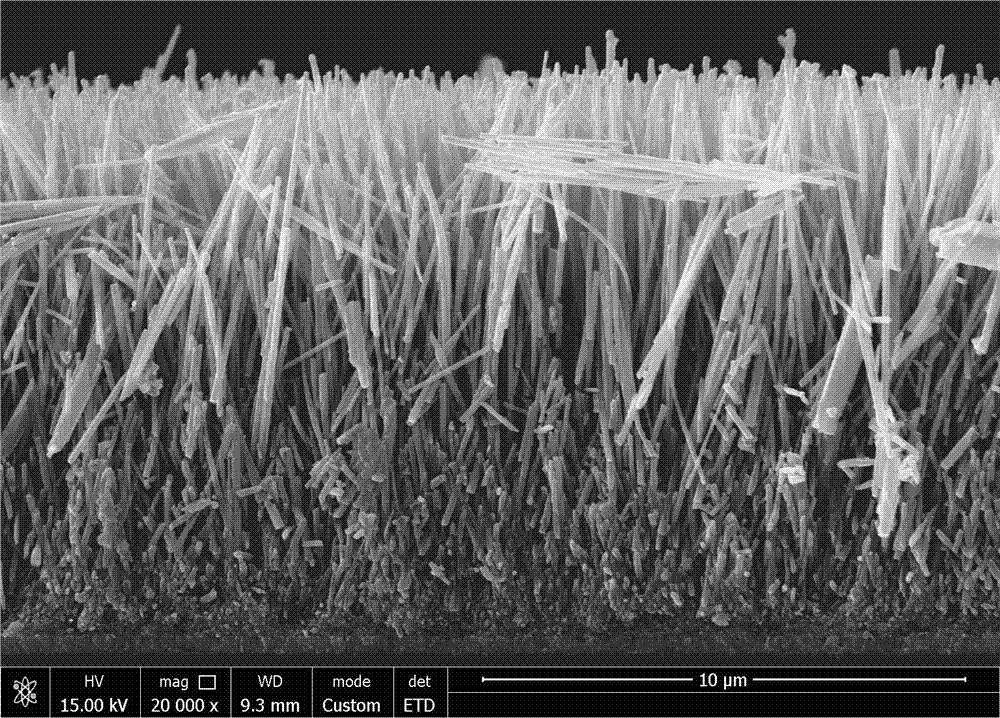

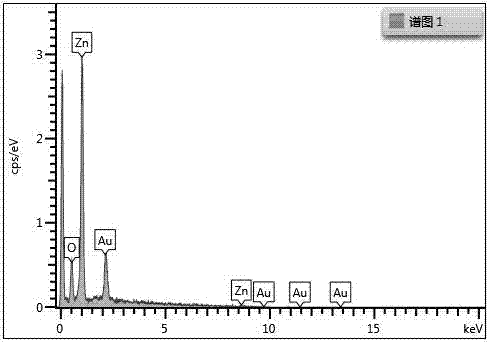

[0027] Step (2): Put the conductive glass with the seed layer prepared in the previous step into an aqueous solution consisting of 25mM zinc nitrate hexahydrate, 12.5mM hexamethylenetetramine, 1.2mM polyethyleneimine and 1.2mL ammonia water, at 88 o Hydrothermal growth under C conditions for 8 hours; the scanning electron microscope image of the ZnO nanowire array prepared in this step is as follows figure 1 As shown, its EDX spectrum is as figure 2 It can be seen from the two figures that the prepared product is an ordered nanowire array, which is ma...

Embodiment 2

[0029] Embodiment 2: Prepare ZnO / I doped ZnO core / shell structure nanowire array according to the following steps:

[0030] Step (1): Spin-coat an ethanol solution containing 0.45M ethanolamine and 0.45M zinc acetate on the cleaned FTO conductive glass substrate, dry the film obtained by spin coating, and place it in a 500 o Annealed in the muffle furnace of C for 45 minutes, obtained the conductive glass with ZnO seed layer;

[0031] Step (2): Put the conductive glass with the seed layer prepared in the previous step into an aqueous solution consisting of 50mM zinc nitrate hexahydrate, 25mM hexamethylenetetramine, 1.35mM polyethyleneimine and 1.35mL ammonia water. 88 o 11.5 hours of hydrothermal growth under C conditions;

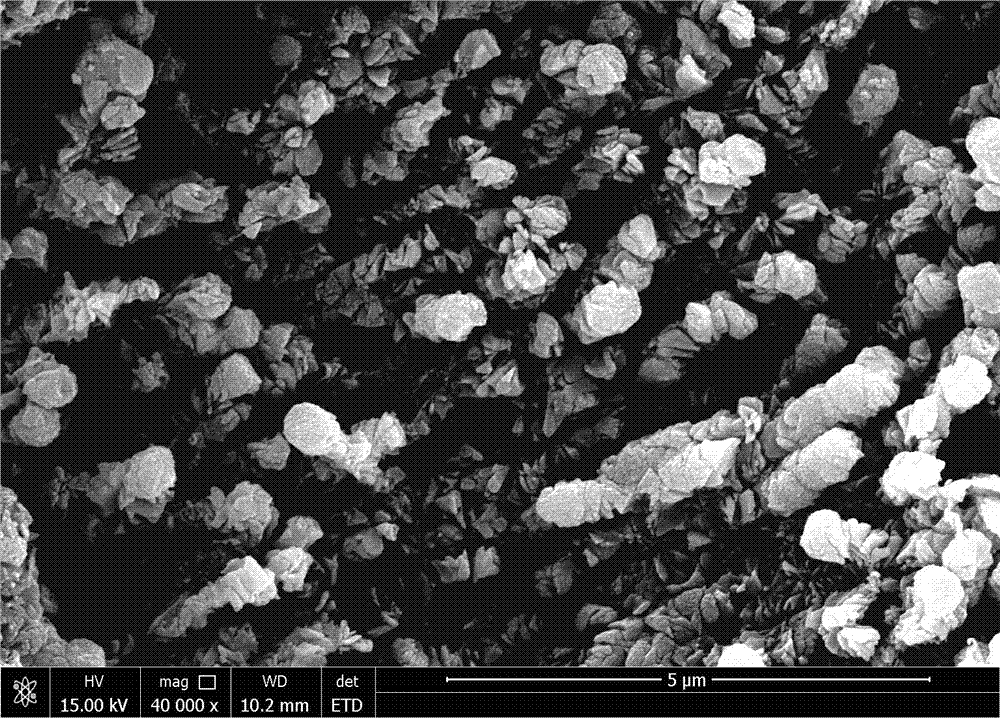

[0032] Step (3): Put the substrate with ZnO nanowires on the surface in a solution containing 0.0024M iodic acid, 0.06M zinc acetate and 0.03M hexamethylenetetramine in a blast drying oven at 62 o Heating in C environment for 13.5 hours, ZnO / I doped ZnO...

Embodiment 3

[0033] Embodiment 3: Prepare ZnO / I doped ZnO core / shell structure nanowire array according to the following steps:

[0034] Step (1): Spin-coat an ethanol solution containing 0.6M ethanolamine and 0.6M zinc acetate on the cleaned FTO conductive glass substrate, dry the film obtained by spin coating, and place it in a 500 o Annealed in the muffle furnace of C for 60 minutes to obtain a conductive glass with a ZnO seed layer;

[0035] Step (2): Put the conductive glass with the seed layer prepared in the previous step into an aqueous solution consisting of 75mM zinc nitrate hexahydrate, 37.5mM hexamethylenetetramine, 1.5mM polyethyleneimine and 1.5mL ammonia water, at 88 o Hydrothermal growth under C conditions for 15 hours;

[0036] Step (3): Put the substrate with ZnO nanowires on the surface in a solution containing 0.0036M iodic acid, 0.06M zinc acetate and 0.03M hexamethylenetetramine in a blast drying oven at 62 o C environment was heated for 15 hours to obtain a ZnO / I ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com