Preparation method of three-dimensional electrode slice based on aqueous adhesive

A water-based binder, three-dimensional electrode technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of high price of foamed graphite mesh, insufficient ductility, and the bonding firmness needs to be further improved. Effects of improving electron conductivity and improving discharge rate characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

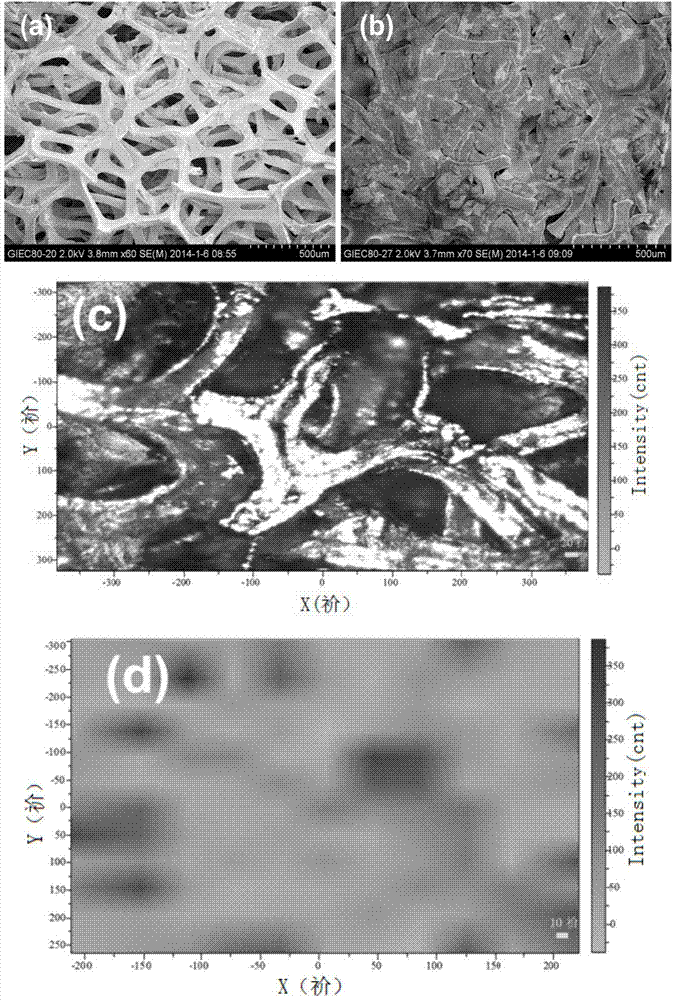

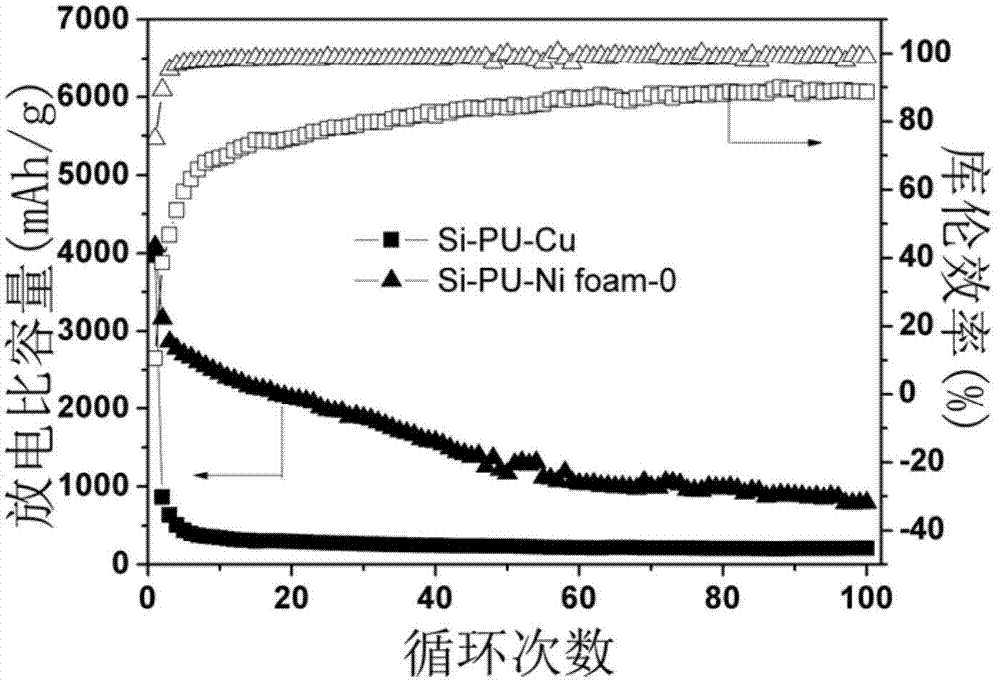

[0035] Embodiment 1: An embodiment of the preparation method of the three-dimensional electrode pole piece based on the aqueous binder of the present invention

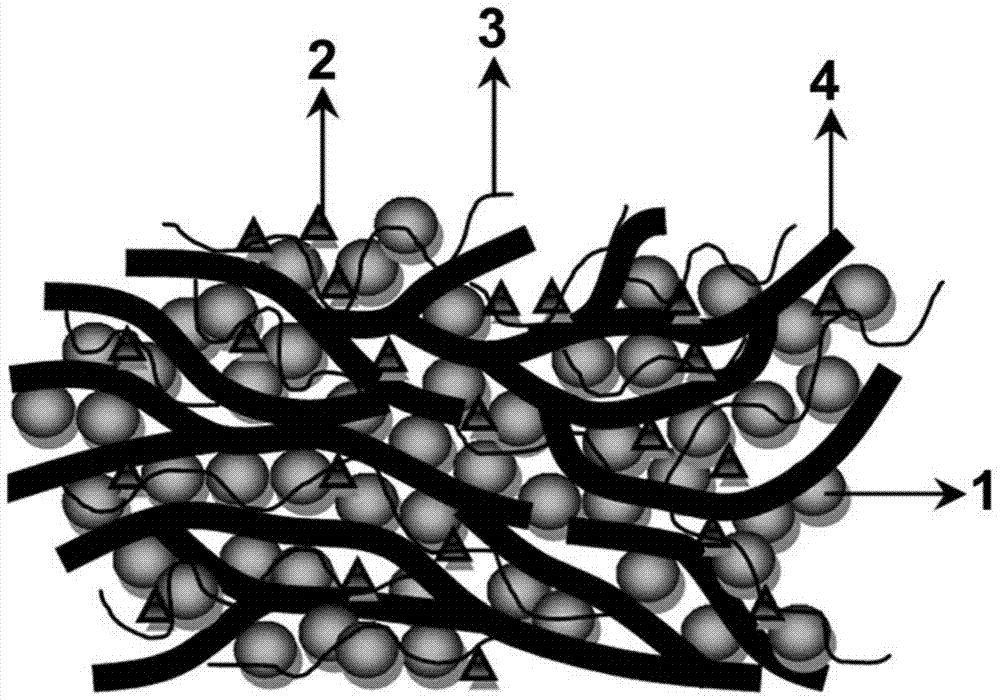

[0036] A water-soluble polyurethane (PU) solution with a concentration of 3.8 wt.% is used as a binder, elemental silicon powder is used as the negative electrode active material, acetylene black is used as a conductive agent, and three-dimensional porous nickel foam is used as a collector to prepare a three-dimensional silicon negative electrode. Experimental steps:

[0037] Fabrication of a three-dimensional silicon negative electrode piece: mixing the negative electrode active material, the binder, and the conductive agent to obtain a mixture, where the weight percentage of the negative electrode active material is 70% based on the total weight of the mixture The weight percentage of the binder is 10%, and the weight percentage of the conductive agent is 20%; the resulting mixture is adjusted to a negative electrode slu...

Embodiment 2

[0041] Embodiment 2: An embodiment of the preparation method of the three-dimensional electrode pole piece based on the aqueous binder of the present invention

[0042] A 2wt.% sodium carboxymethylcellulose (CMC) aqueous solution was used as a binder, acetylene black was used as a conductive agent, elemental silicon powder was used as the negative electrode active material, and three-dimensional porous nickel foam was used as a collector to prepare a three-dimensional silicon negative electrode. Film, experimental steps:

[0043] Fabrication of the three-dimensional silicon negative electrode piece: mixing the negative electrode active material, the binder, and the conductive agent to obtain a mixture, wherein the weight percentage of the negative electrode active material is 90% based on the total weight of the mixture The weight percentage of the binder is 1%, and the weight percentage of the conductive agent is 9%; the resulting mixture is adjusted into a negative electrode slur...

Embodiment 3

[0047] Embodiment 3: An embodiment of the preparation method of the three-dimensional electrode pole piece based on the aqueous binder of the present invention

[0048] A three-dimensional silicon anode electrode piece prepared with a 5wt.% aqueous solution of carboxylated chitosan (C-CTS) as a binder, acetylene black as a conductive agent, and three-dimensional porous nickel foam as a current collector. Experimental steps:

[0049] Fabrication of three-dimensional silicon negative pole piece: mixing the above negative active material, the above binder and the above conductive agent to obtain a mixture, wherein based on the total weight of the mixture, the weight percentage of the negative active material is 80% , The weight percentage of the binder is 5%, and the weight percentage of the conductive agent is 15%; the resulting mixture is adjusted into a negative electrode slurry with a viscosity of 3000 cps with water as a solvent, and a 1.0mm thick three-dimensional The porous nic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com