Compound chitin -potassium titanate crystal whisker membrane and preparation method thereof

A technology of potassium titanate whiskers and chitin whiskers, which is applied in the field of chitin-potassium titanate composite whisker films and its preparation, can solve the problem of not finding composite films made of chitin whiskers and potassium titanate whiskers Relevant research and other issues, to achieve excellent antibacterial, wide source, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

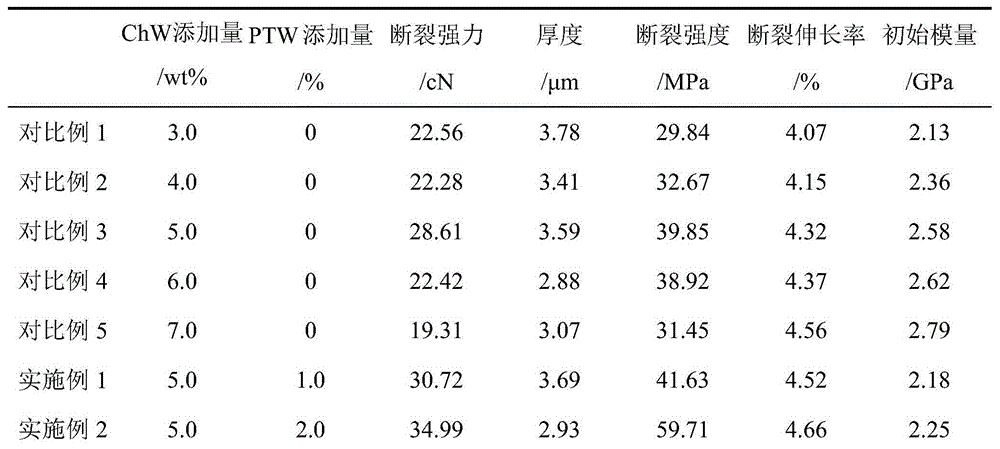

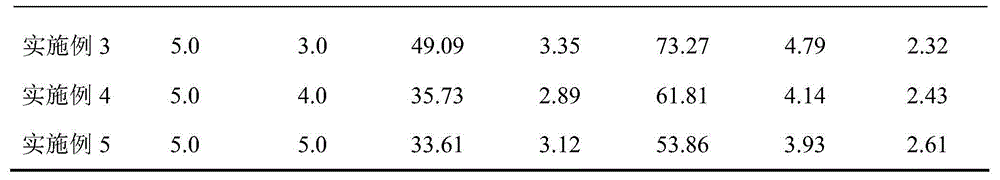

Embodiment 1

[0048] Preparation of chitin-potassium titanate composite whisker film:

[0049] Take a beaker filled with 90mL of cold water at 20°C, slowly add 10mL of 15% polyvinyl alcohol into it and stir, after fully swelling, dispersing and volatile substances escape, transfer the 30mL solution in the beaker to the In a four-neck flask containing 10 g of potassium hexatitanate whiskers, the temperature of the water bath was gradually raised to 80°C, stirred for 30 minutes, transferred to a watch glass to dry, dried at 80°C for 3 hours, and cooled to room temperature to obtain polyvinyl alcohol modified Potassium hexatitanate whisker products.

[0050] Weigh 5.0g of chitin whiskers, add it to 95mL of 88% formic acid solution, ultrasonicate for 30min, disperse evenly, seal it, place it in -10℃ for 24h, take it out, and thaw it at room temperature; and perform another freeze-thaw operation , and then get chitin whisker colloid viscous liquid. The viscous solution was placed in a dialysis...

Embodiment 2

[0052] Preparation of chitin-potassium titanate composite whisker film:

[0053] Take a beaker containing 90mL of cold water at 22°C, slowly add 10mL of 15% PDMC into it and stir, after fully swelling, dispersing and volatile substances escape, transfer the solution in the 30mL beaker to a container containing 10g of six In a four-necked flask containing potassium titanate whiskers, the water bath was gradually heated to 85°C, stirred for 40 minutes, then transferred to a watch glass to dry, dried at 85°C for 2 hours, and cooled to room temperature to obtain PDMC-modified hexatitanic acid Potassium whisker products.

[0054] Weigh 5.0g of chitin whiskers, add it to 95mL of 88% formic acid solution, sonicate for 20min, disperse evenly, seal it, place it in -20℃ for 20h, take it out, and thaw it at room temperature; and perform another freeze-thaw operation , and then get chitin whisker colloid viscous liquid. The viscous solution was placed in a dialysis bag, and dialyzed wit...

Embodiment 3

[0056] Preparation of chitin-potassium titanate composite whisker film:

[0057] Take a beaker containing 90mL of cold water at 25°C, slowly add 12mL of 15% polyvinyl alcohol into it and stir, after fully swelling, dispersing and volatile substances escape, transfer the solution in the 30mL beaker to a container with In a four-necked flask containing 10 g of potassium hexatitanate whiskers, the temperature of the water bath was gradually raised to 82°C, stirred for 30 minutes, transferred to a watch glass to dry, dried at 75°C for 4 hours, and cooled to room temperature to obtain polyvinyl alcohol modified Potassium hexatitanate whisker products.

[0058] Weigh 5.0g of chitin whiskers, add them to 95mL of 88% formic acid solution, ultrasonicate for 40min, disperse evenly, seal, place in -15°C for 26h, take out, and thaw at room temperature; times, and then obtain chitin whisker colloid viscous liquid. The viscous solution was placed in a dialysis bag, and dialyzed with deion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com