Heat-conducting and insulated composite material based on carbon nanotubes and preparation method for composite material

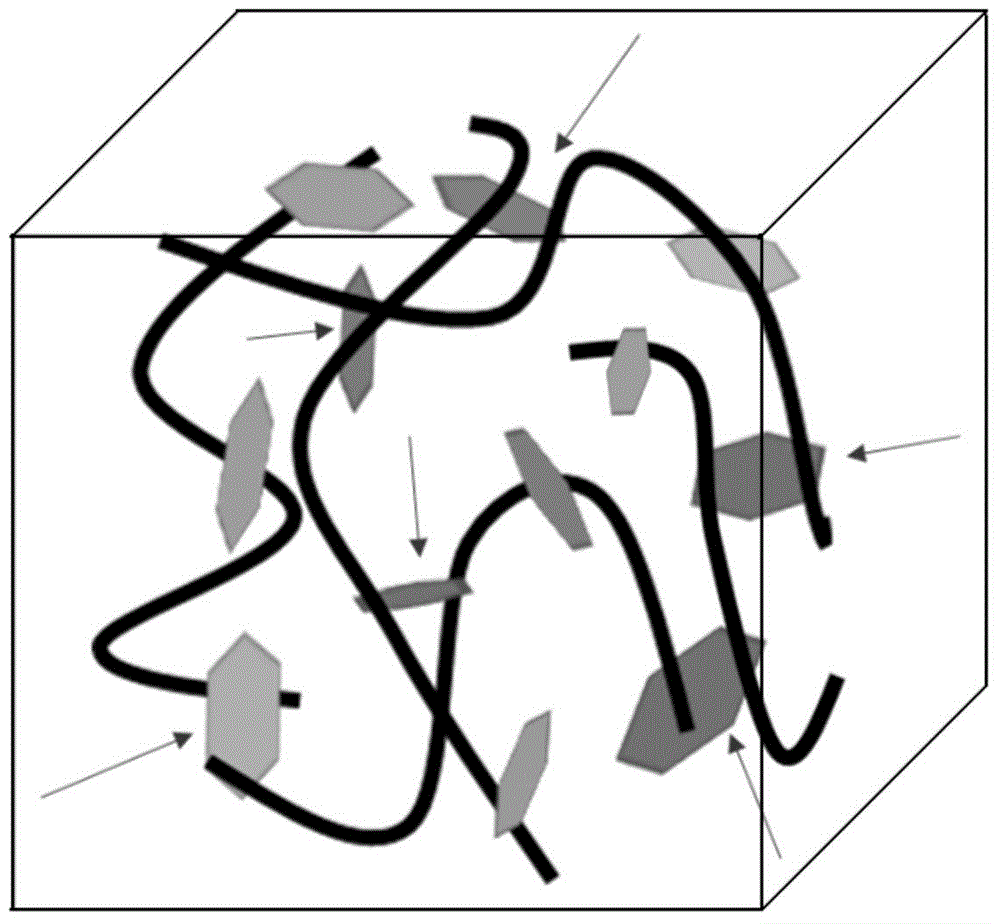

A technology of carbon nanotubes and composite materials, which is applied in the field of thermally conductive and insulating composite materials based on carbon nanotubes and its preparation, which can solve the problems of poor fluidity, decreased mechanical properties, and inability to transfer composite materials, and achieve good insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The thermally conductive and insulating composite material based on carbon nanotubes consists of the following components in parts by weight: 100 parts of polypropylene, 25 parts of boron nitride, 4.5 parts of multi-walled carbon nanotubes after treatment, 1 part of silicon-oxygen coupling agent, 0.3 parts of phenolic 1010, 2.5 parts of paraffin.

[0033] The preparation method of the above-mentioned thermally conductive and insulating composite material based on carbon nanotubes is as follows:

[0034] First dry polypropylene and boron nitride at 80°C, and then take the proportioned amount of each component and pass it through a twin-screw extruder at the temperature of each section at 160, 180, 195, 200, 200, 210 and 200°C Extrude and granulate, dry at 70-90°C, and then shape and prepare samples.

[0035] The thermal conductivity of the above-mentioned carbon nanotube-based thermally conductive and insulating composite material tested after sample preparation is 0.48...

Embodiment 2

[0037] The thermally conductive and insulating composite material based on carbon nanotubes consists of the following components in parts by weight: 100 parts of polypropylene, 40 parts of boron nitride, 3.5 parts of treated carbon nanotubes, 1.5 parts of silicon-oxygen coupling agent, phenols 0.4 parts of 1010, 3.5 parts of paraffin.

[0038] The preparation method of the above-mentioned carbon nanotube-based thermally conductive and insulating composite material is the same as that in Example 1.

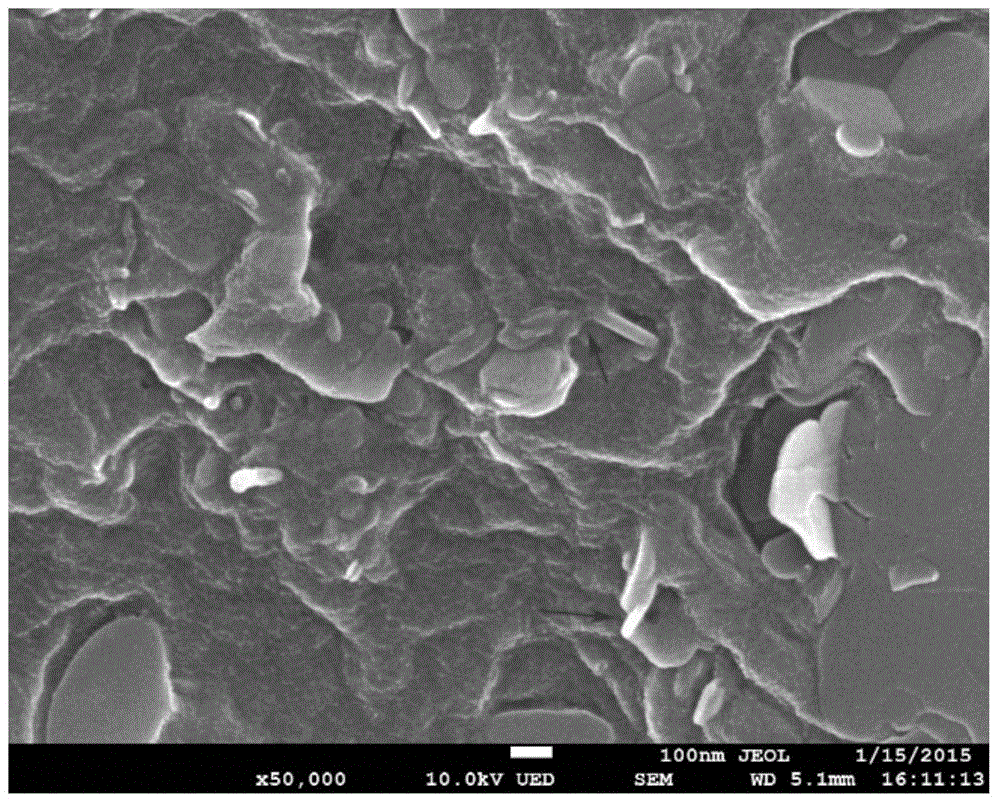

[0039] The scanning electron microscope image of the thermally conductive and insulating composite material based on carbon nanotubes obtained in this embodiment is as follows figure 2As shown, due to the size distribution of the blended boron nitride in a certain range under the shear force, the boron nitride is uniformly dispersed in the matrix; in the scanning electron microscope image, the carbon nanotube conjugate system contains more electrons, and during the irradiation pro...

Embodiment 3

[0041] The thermally conductive and insulating composite material based on carbon nanotubes consists of the following components in parts by weight: 100 parts of polyphenylene sulfide, 45 parts of boron nitride, 3 parts of treated carbon nanotubes, and 1.5 parts of titanate coupling agent , 0.4 parts of phosphite ester 168, 3.5 parts of fatty acid lubricant.

[0042] The preparation method of the above-mentioned thermally conductive and insulating composite material based on carbon nanotubes is as follows:

[0043] First, dry polyphenylene sulfide and boron nitride at 90°C, and then take the proportioned amount of each component and pass it through a twin-screw extruder at the temperature of each section at 150, 300, 300, 290, 300 and 310°C Extrude and granulate, dry at 80-100°C, and then shape and prepare samples.

[0044] The thermal conductivity of the above-mentioned carbon nanotube-based thermally conductive and insulating composite material tested after sample preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com