Calcium carbide furnace tail gas dry dedusting, waste heat recovery and synthesis gas production device

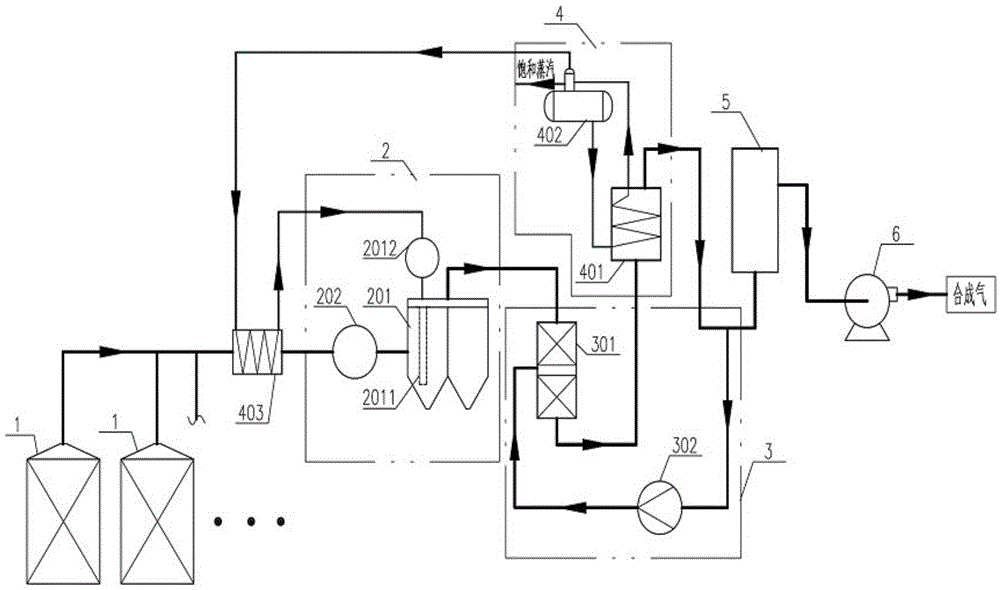

A technology for recovering exhaust gas and waste heat from a calcium carbide furnace, which is applied to combined devices, furnaces, waste heat treatment, etc., can solve the problems of high water and energy consumption, difficult sewage, and difficulty in ensuring the stable operation of the system and meeting the purification requirements. The effect of advanced technology, high temperature calcium carbide furnace tail gas energy and resource recovery efficiency maximization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0053] A 200,000-ton / year calcium carbide production line in a certain factory is equipped with two 48,000KVA sealed calcium carbide furnaces, and the total normal flow rate of the calcium carbide furnace tail gas is 11,000Nm 3 / h, the temperature is normally 400-600°C, and the exhaust gas composition and dust characteristics are shown in Table 1, Table 2, and Table 3:

[0054] Table 1. Composition of calcium carbide furnace exhaust gas

[0055] name

CO

H 2

CO 2

N 2

O 2

other

dust

Content (V%)

70~90

2~6

1~3

2~5

0.2~1

~1

120g / Nm 3

[0056] Table 2. Composition of dust carried by the tail gas of calcium carbide furnace

[0057] Dust composition

CaO

C

SiO 2

Fe 2 o 3

Al 2 o 3

other

Percentage (W%)

37.2

34.1

15.8

0.96

7.1

~4.84

[0058] Table 3. Particle size distribution of dust carried by calcium carbide furnace ta...

specific Embodiment 2

[0067] A 200,000-ton / year calcium carbide production line in a certain factory is equipped with a complete set of equipment for regenerative calcium carbide production. This device produces H 2 ≈8700Nm 3 / h, the matching of the closed calcium carbide furnace is similar to that of Example 1, and the output and composition properties of the calcium carbide tail gas are also similar to those of Example 1. In this example, the ratio of CO gas recovered from the calcium carbide furnace tail gas and the ratio of by-product hydrogen to carry out methanation reaction The production of LNG is 22,000 tons / year.

[0068] The production scheme of this example is similar to that of Example 1, the difference is that this example does not have a calcium carbide tail gas composition reforming system 3 after the high-temperature calcium carbide tail gas dedusting system, and all effective CO gases pass through the high-temperature calcium carbide tail gas waste heat recovery system 4 and low-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com