Method for preparing nanometer ZnS/cellulose complex film with photocatalytic activity

A photocatalytic activity, cellulose technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, chemical/physical processes, etc., can solve problems such as easy agglomeration and poor stability of inorganic nano-ZnS particles , to achieve the effect of improving catalytic activity, simple equipment, low consumption of chemical raw materials and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of Cellulose Membrane

[0034] One of the 2g cotton pulp cellulose, wood pulp cellulose or straw pulp cellulose after pulverization is added to the NMMO solvent and 0.02g ascorbic acid (mass approx. 1% of the element weight) in a beaker, prepare a casting solution with a cellulose content of about 6%, and stir evenly; after swelling for 2 hours, put it in a vacuum drying oven at 110°C to dissolve completely, and wait until the solution is amber and uniform When the solution is transparent, place it at 80°C for vacuum defoaming for 4 hours, and scrape the film; then, treat it with a coagulation bath (about 25°C deionized water) and a water bath (about 25°C deionized water) to obtain wet pure cotton pulp fibers plain film.

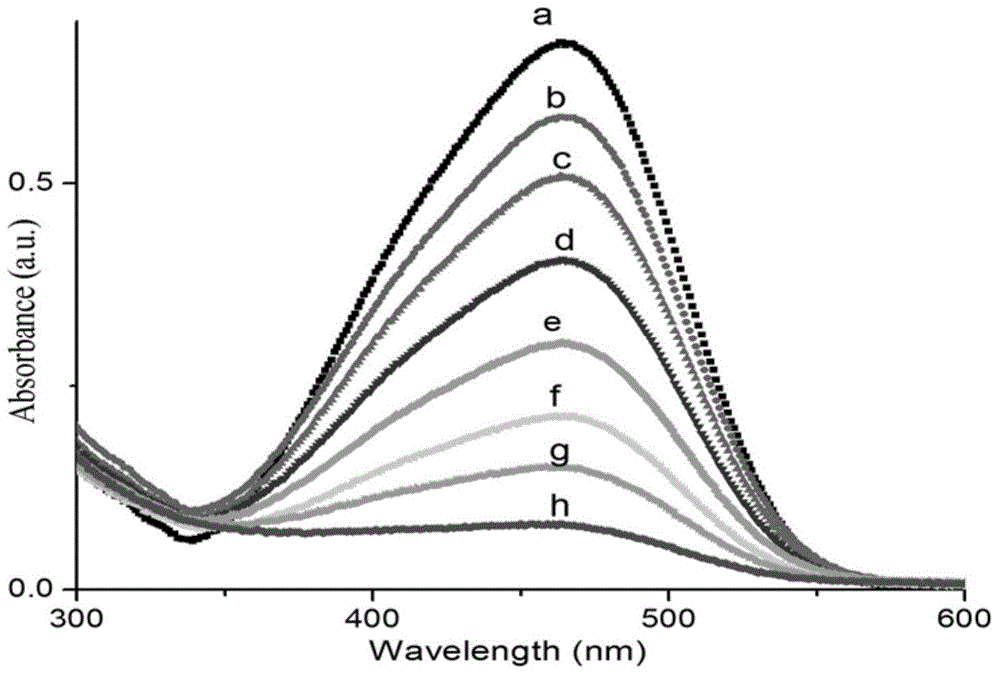

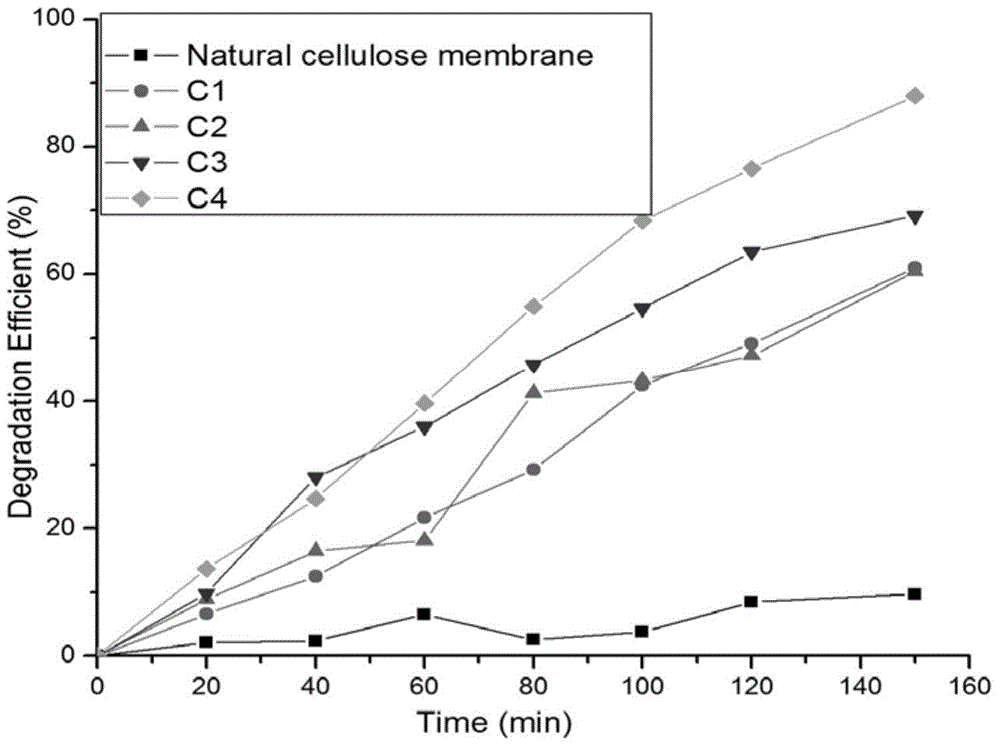

[0035] 2. Preparation of nano-ZnS / cellulose composite membrane material with photocatalytic activity

[0036] Cut the above wet film into a film with a size of 10cm×15cm, soak it in 0.1M zinc sulfate precursor solution, react for 5h, ...

Embodiment 2

[0038] 1. Preparation of Cellulose Membrane

[0039] The preparation of the cellulose film was the same as in Example 1.

[0040] 2. Preparation of nano-ZnS / cellulose composite membrane material with photocatalytic activity

[0041] Cut the above wet film into a film with a size of 10cm×15cm, soak it in 0.1M zinc sulfate precursor solution, react for 5h, take it out and rinse it with deionized water; then put it into 0.1M sodium sulfide After reacting for 5 hours in the precursor solution, take it out and rinse it with deionized water. The above process is a cycle, and then the second cycle of impregnation experiment is carried out. After the impregnation is completed, the sample film is naturally dried at room temperature to obtain a nano-ZnS / cellulose composite membrane material with photocatalytic activity that is impregnated twice.

Embodiment 3

[0043] 1. Preparation of Cellulose Membrane

[0044] The preparation method of the cellulose film is the same as that of Example 1.

[0045] 2. Preparation of nano-ZnS / cellulose composite membrane material with photocatalytic activity

[0046]Cut the above wet film into a film with a size of 10cm×15cm, soak it in 0.1M zinc sulfate precursor solution, react for 5h, take it out and rinse it with deionized water; then put it into 0.1M sodium sulfide After reacting for 5 hours in the precursor solution, take it out and rinse it with deionized water. The above process is a cycle, and then repeat the impregnation experiment twice. After the impregnation is completed, the sample film is naturally dried at room temperature to obtain a nano-ZnS / cellulose composite membrane material with photocatalytic activity that has been impregnated three times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com