Preparation method of silicon dioxide coated crystal water-salt phase-change material microcapsules

A technology of silicon dioxide and water of crystallization, applied in microcapsule preparations, chemical instruments and methods, microsphere preparation, etc. The effect of variable latent heat, low price and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

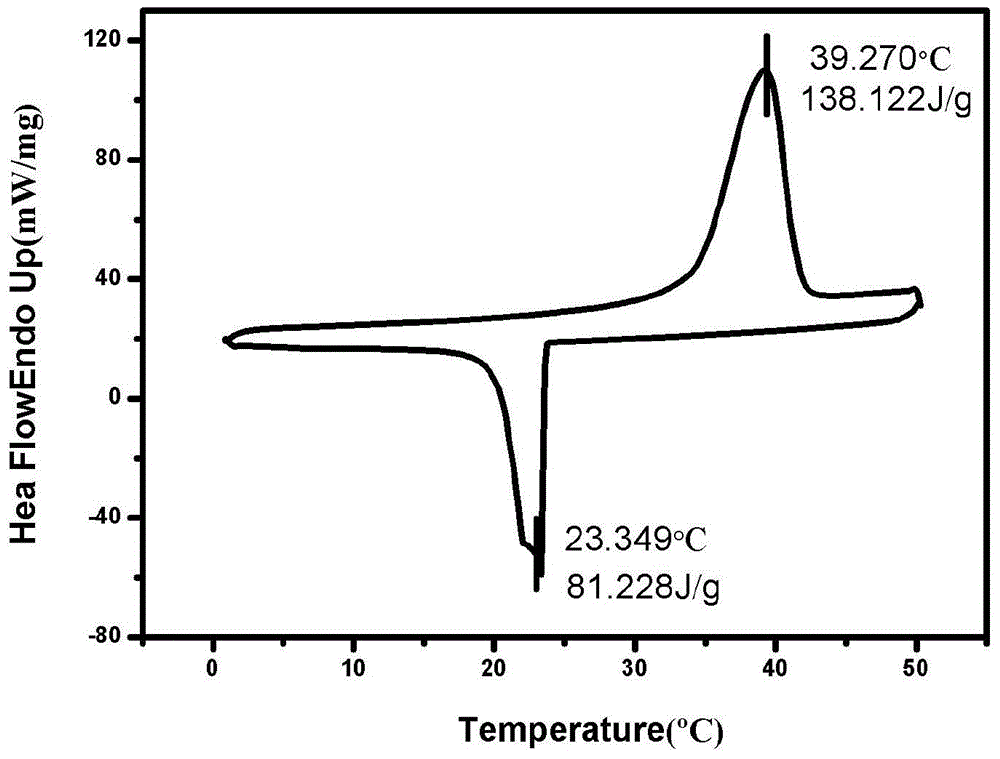

[0033] Weigh 6.2gCaCl 2 ·6H 2 O was mixed with 10ml of water, and a certain amount of ammonia water was added to adjust the pH to 8 to obtain the mixed solution A. Weigh 0.2g of sodium dodecylbenzenesulfonate and add it to 25ml of cyclohexane and stir at 2000rpm in a water bath at 45°C, add the above-mentioned A mixture to it, and stir for 20min, stale for 2h, and form a stable W / O emulsion. Then add dropwise 1ml of a mixture of ethyl orthosilicate and dimethyldiethoxysilane with a volume ratio of 1:1, then stir at 1000rpm for 24h, then centrifuge in a centrifuge at 5400r / min for 10min to obtain microcapsules , washed three times by centrifugation with deionized water and then dried at 20°C to obtain the product. The latent heat of phase change of the obtained product is 138.122 J / g. Its DSC phase transition curve is shown in figure 1 shown.

Embodiment 2

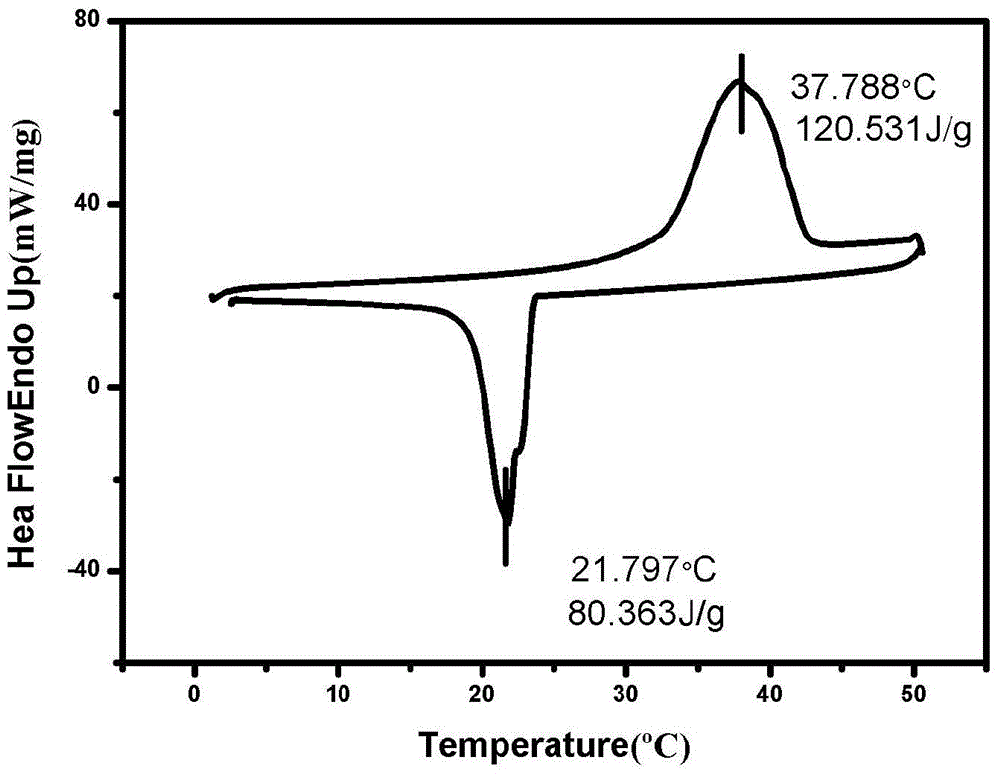

[0035] Weigh 6g Na 2 SO 4 10H 2 O was mixed with 30ml of water, and a certain amount of ammonia water was added to adjust the pH to 9 to obtain the mixed solution B. Weigh 1.3g SPAN80 and add it to 130ml cyclohexane and stir at 2000rpm in a water bath at 45°C, add the above B mixture into it, and stir for 20min, then stale for 2h to form a stable W / O emulsion. Then dropwise add 25ml of a mixture of ethyl orthosilicate and dimethyldiethoxysilane with a volume ratio of 1:1.2, then stir at 1000rpm for 24h, then centrifuge for 10min in a centrifuge at 5400r / min to obtain microcapsules , washed three times by centrifugation with deionized water and then dried at 20°C to obtain the product. The latent heat of phase change of the obtained product is 120.531 J / g. Its DSC phase transition curve is shown in figure 2 shown.

Embodiment 3

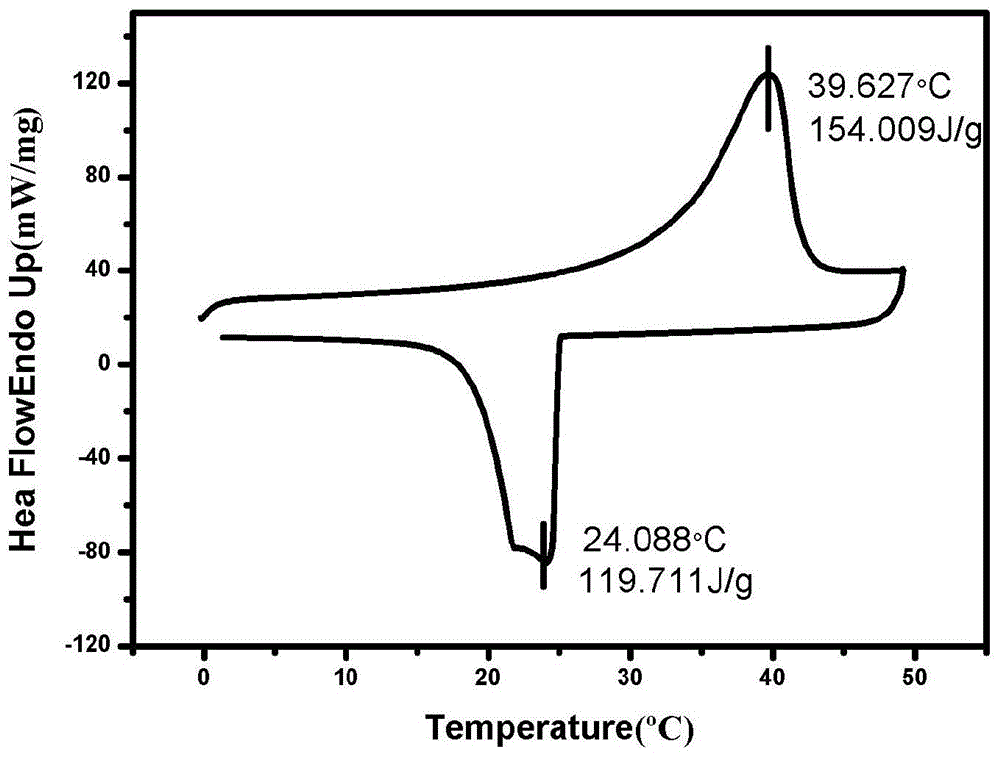

[0037] Weigh 6.2g Na 2 SO 4 10H 2 Mix O with 20ml of water, add a certain amount of ammonia water, adjust the pH to 8, and obtain the mixed solution C. Weigh 0.8g of SDS and add it to 80ml of hexadecane and stir at 2000rpm in a water bath at 45°C, add the above C mixture into it, and stir for 20min, then stale for 2h to form a stable W / O emulsion. Then dropwise add 2ml of a mixture of ethyl orthosilicate and dimethyldiethoxysilane with a volume ratio of 1:1.5, then stir at 1000rpm for 24h, then centrifuge in a centrifuge at 5400r / min for 10min to obtain microcapsules , washed three times by centrifugation with deionized water and then dried at 20°C to obtain the product. The latent heat of phase change of the obtained product is 154.009 J / g. Its DSC phase transition curve is shown in image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Latent heat of phase change | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com