Method for catalyzing esterification reaction by means of high-stable-acidity mesoporous-microporous molecular sieve

A technology of molecular sieve catalyzing esters and microporous molecular sieves, applied in molecular sieve catalysts, fatty acid esterification, chemical instruments and methods, etc., can solve the problems of low conversion rate of oleic acid and high reaction temperature of 160 °C, and achieve stable catalytic performance, high heat Strong stability and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] The preparation of β / Al-MCM-41 catalyst: the β / Al-MCM-41 catalyst of n(Si):n(Al)=30 is prepared by stepwise crystallization method, and the synthesis steps are as follows: NaOH, NaAlO 2 , SiO 2 Aqueous solution (mass fraction 30%) and mass fraction are the aqueous solution of TEAOH of 25% according to molar ratio n (Al 2 o 3 ) / n(SiO 2 ) / n(Na 2 O) / n(TEAOH) / n(H 2 (2) = 1.0 / 60 / 2.5 / 22 / 800 ratio mixing, and stirring, then the mixture is transferred to the autoclave, dissolved at 140 ° C for 4 hours, the resulting clear solution, namely Beta zeolite directing agent; Add the Beta zeolite directing agent into cetyltrimethylammonium bromide (CTAMBr) aqueous solution, mix and stir for 30min, adjust the pH value with 5mol / L sulfuric acid, add ethanol; In a tetrafluoroethylene-lined stainless steel reactor, seal it, and after crystallization, suction filter, wash, dry, and roast to obtain a β / Al-MCM-41 molecular sieve catalyst, which is ready for use.

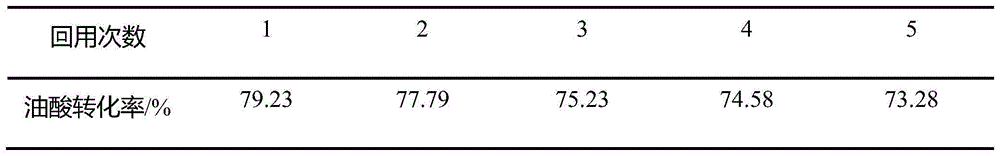

[0012] With 10 grams o...

Embodiment 2

[0014] The preparation of β / Zr-MCM-41 catalyst: the β / Zr-MCM-41 catalyst of n(Si): n(Al)=30 is prepared by stepwise crystallization method, and the synthesis steps are as follows: NaOH, NaAlO 2 , SiO 2 Aqueous solution (mass fraction 30%) and mass fraction are the aqueous solution of TEAOH of 25% according to molar ratio n (Al 2 o 3 ) / n(SiO 2 ) / n(Na 2 O) / n(TEAOH) / n(H 2 (2) = 1.0 / 60 / 2.5 / 22 / 800 ratio mixing, and stirring, then the mixture is transferred to the autoclave, dissolved at 140 ° C for 4 hours, the resulting clear solution, namely Beta zeolite directing agent; Add the Beta zeolite directing agent into the cetyltrimethylammonium bromide (CTAMBr) aqueous solution, mix and stir for 30min, add Zr(SO 4 ) 2 The aqueous solution (Si / Zr=1 / 0.05) was continuously mixed and stirred for 30 min, the pH value was adjusted with 5 mol / L sulfuric acid, and ethanol was added; stirred for 1 h at room temperature, the mixed solution was transferred into a stainless steel reactor lin...

Embodiment 3

[0017] The preparation of β / Sn-MCM-41 catalyst: preparation condition and step are with embodiment 2, just Zr(SO 4 ) 2 The aqueous solution is changed into SnCl4 aqueous solution.

[0018] Experimental condition and step are the same as embodiment 1, just change catalyst β / Al-MCM-41 into catalyst β / Sn-MCM-41, when alcohol-oil ratio is 10: 1, catalyst consumption accounts for 5% of reactant quality, 120 The highest conversion rate of oleic acid was 70.12% when reacting at ℃ for 8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com