Felt for vacuum insulation panel, method for producing same, and vacuum insulation panel using same

A technology of vacuum insulation panels and fiber mats, which is applied in textiles, papermaking, non-woven fabrics, etc., and can solve problems such as potential risks to human health and the increase in lung cancer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

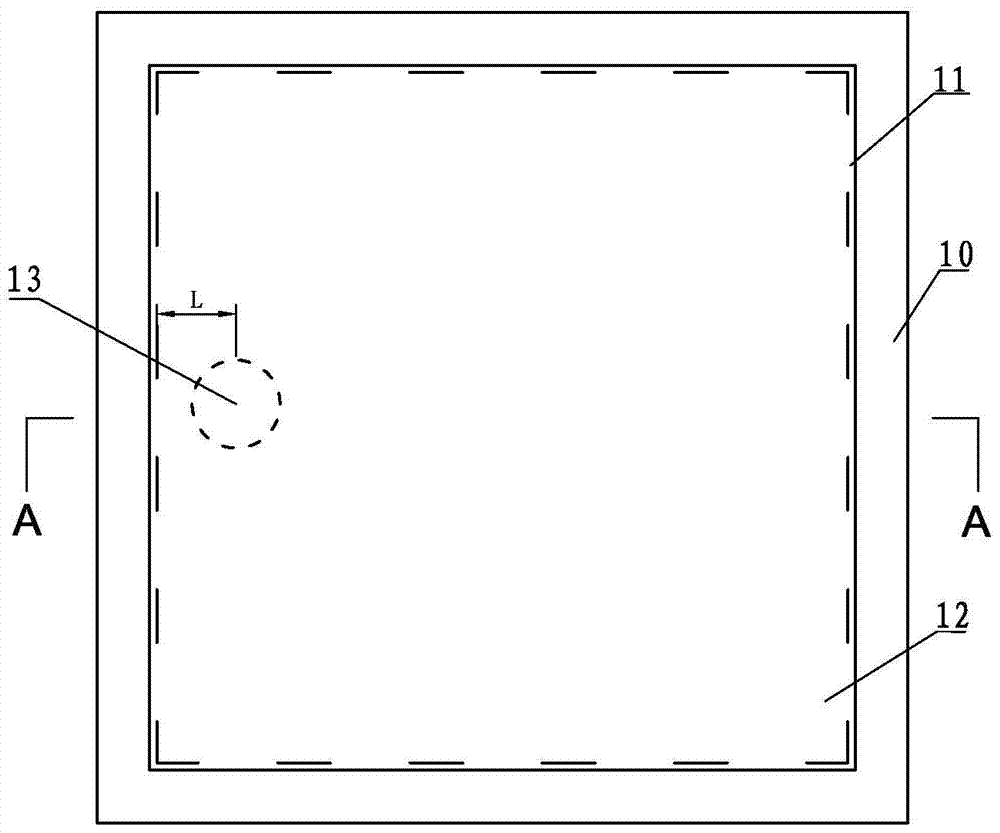

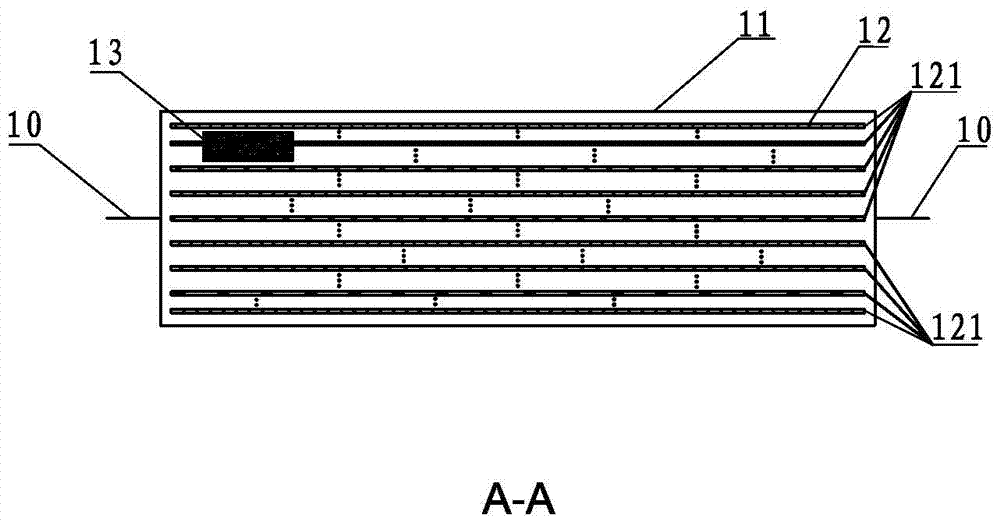

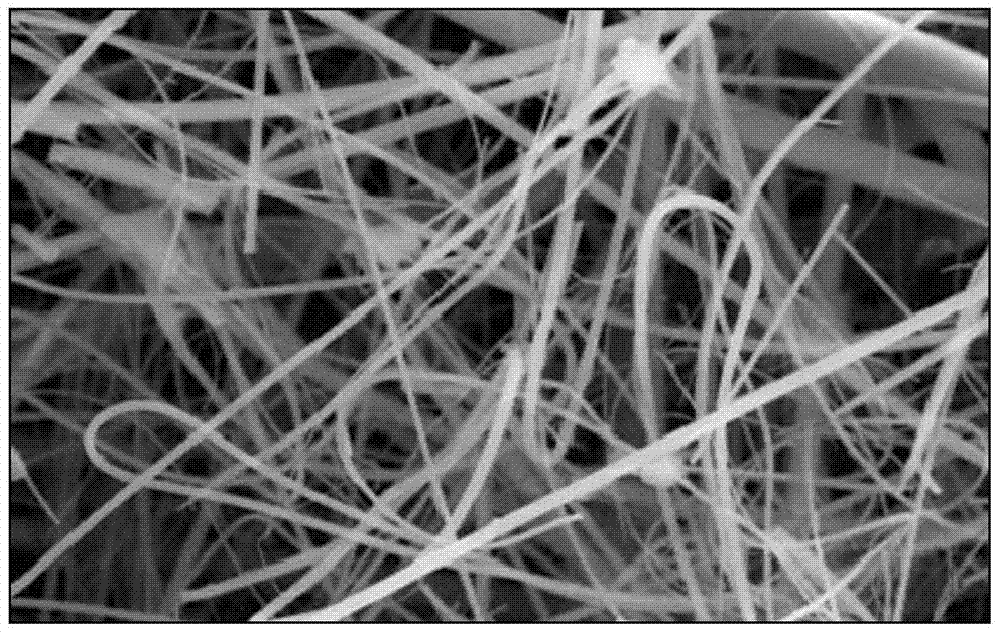

[0090] An embodiment of the felt used for vacuum insulation panels of the present invention, the felt is composed of chopped glass fibers, bio-soluble inorganic cotton and adhesive, wherein: the chopped glass fibers are alkali-free glass fibers, R 2 The O content is 0.85wt%, the average fiber diameter is 6.1μm, the average fiber length is 15mm, the sizing agent content is 0.05wt%, and the water content is 9.6wt%. Bio-soluble inorganic cotton is bio-soluble high-temperature-resistant cotton, with a softening point of 950°C, an average fiber diameter of 1 μm, an average fiber length of 30 mm, and a slag ball content of 1 wt%, simulating the dissolution rate constant K in human lung fluid dis 225ng / (cm 2 .hr), the composition of this bio-soluble high temperature resistant cotton is 68wt% SiO 2 , 10wt% CaO, 21wt% MgO, 0.8wt% ZrO 2 , 0.2wt% impurity. The adhesive is 20wt% polyvinyl alcohol resin aqueous solution, brand 0388, manufactured by Shanghai Donghu Industrial Company.

...

Embodiment 2

[0109] In the second embodiment of the felt used for vacuum insulation panels of the present invention: chopped glass fibers are alkali-free glass fibers, R 2 The O content is 0.85wt%, the average fiber diameter is 15μm, the average fiber length is 3mm, the sizing agent content is 0.5wt%, and the water content is 6wt%. The bio-soluble inorganic cotton is bio-soluble glass wool, with a softening point of 500°C, an average fiber diameter of 3 μm, an average fiber length of 50 mm, and a slag ball content of 4.5 wt%. The adhesive is 20wt% polyvinyl alcohol resin aqueous solution, brand 0388, manufactured by Shanghai Donghu Industrial Company.

[0110] The process of preparing the felt is as in the first embodiment, wherein:

[0111] When preparing white water, the white water is made into a thickener concentration of 0.05wt% solution by uniformly mixing the thickener methylcellulose with clear water, and then adding 0.2wt% defoamer (AGTAN 281), 1wt% dispersant (EDAPLAN 480), pre...

Embodiment 3

[0122] In the third embodiment of the felt used for vacuum insulation panels of the present invention: chopped glass fibers are medium-alkali glass fibers, R 2 The O content is 12wt%, the average fiber diameter is 30μm, the average fiber length is 25mm, the sizing agent content is 1.5wt%, and the water content is 14wt%. . The bio-soluble inorganic cotton is bio-soluble glass wool with a softening point of 550°C, an average fiber diameter of 8 μm, an average fiber length of 200 mm, a slag content of 8 wt%, and a Kdis of 195 ng / (cm2.hr). The half-disappearance period of the experiment was less than 40 days. The adhesive is 20wt% polyvinyl alcohol resin aqueous solution, brand 0388, manufactured by Shanghai Donghu Industrial Company.

[0123] The process of preparing the felt is as in the first embodiment, wherein:

[0124] When preparing white water, the white water is prepared by uniformly mixing the thickener methylcellulose and clear water to form a solution with a thicken...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com