Al-base amorphous/nanocrystalline composite solder and preparing method thereof

A nanocrystalline composite and nanocrystalline technology, which is applied in welding/cutting media/materials, manufacturing tools, welding equipment, etc., can solve the problems of difficult clamping of powdered solder, difficult wetting of foil-packed solder, and poor uniformity , to achieve the effect of solving the difficulty of clamping, improving the compactness and joint strength, and increasing the diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

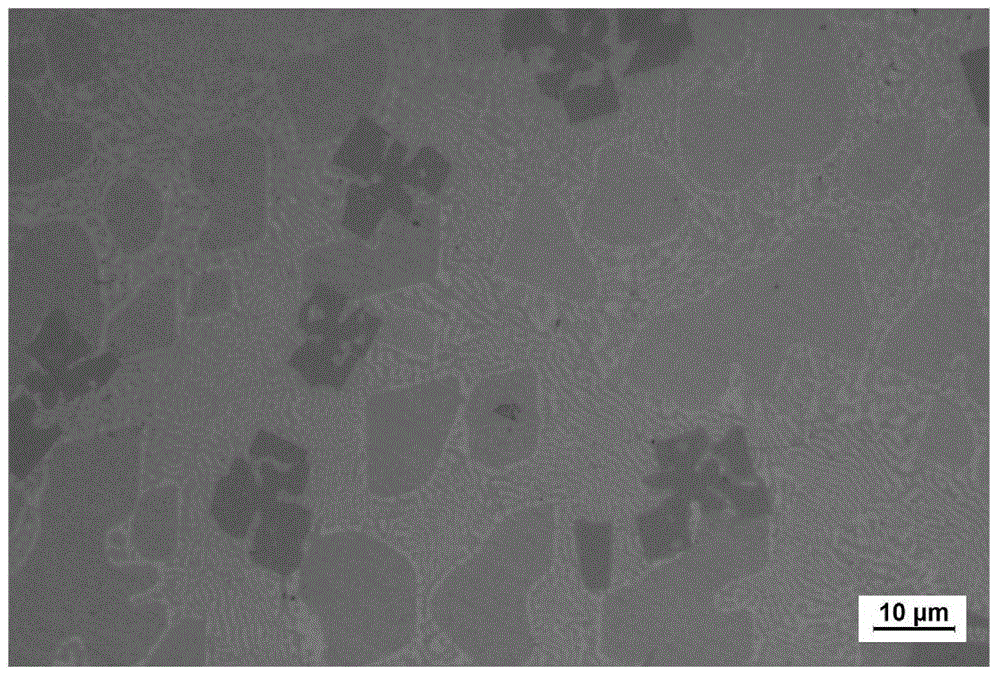

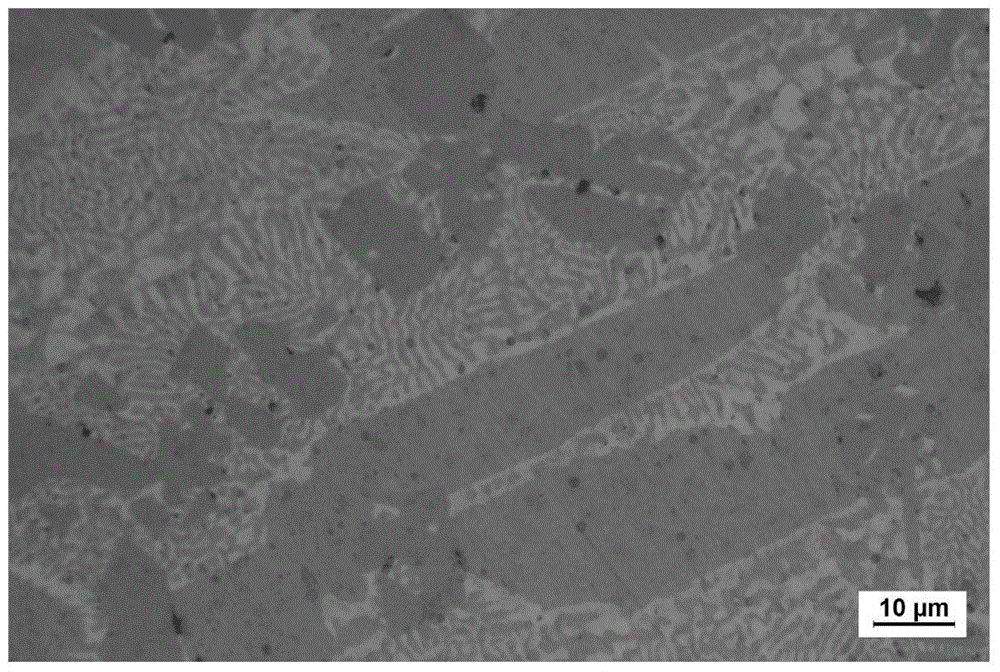

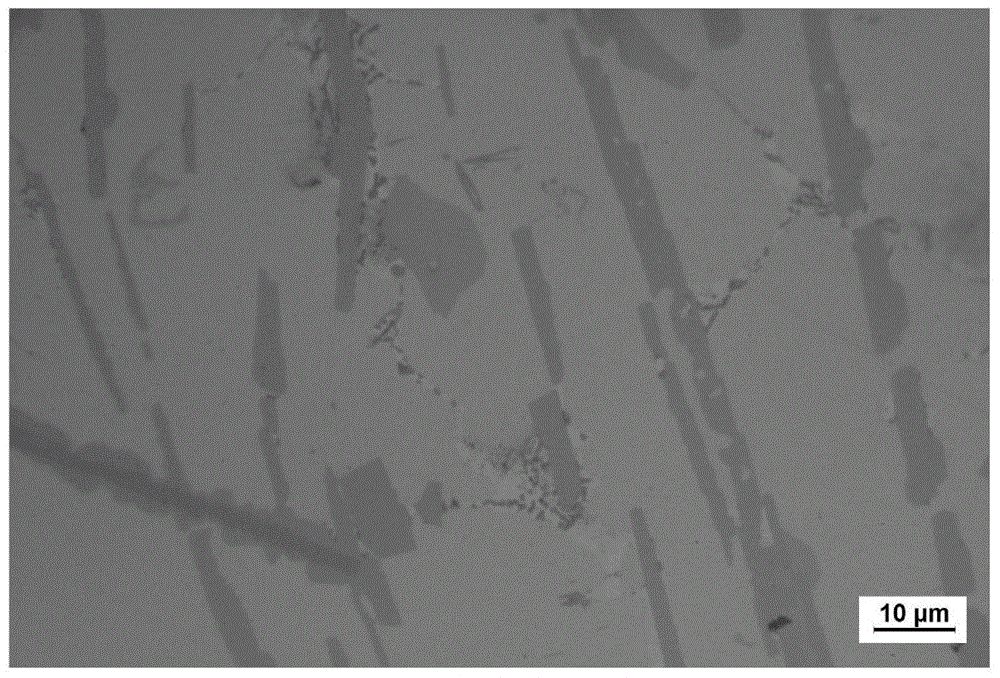

[0022] Specific embodiment one: the present embodiment is an Al-based amorphous / nanocrystalline composite solder, the atomic percentages of Al element, Cu element and Ti element in the Al-based amorphous / nanocrystalline composite solder are (70~ 77):20:(3~10); the Al-based amorphous / nanocrystalline composite solder is an amorphous / nanocrystalline composite structure, wherein the integral fraction of amorphous is 20%~35%, and the integral fraction of nanocrystal is 65% %~80%.

[0023] The Al-based amorphous / nanocrystalline composite solder prepared by rapid solidification by the single-roll method in this embodiment has the following advantages: ① With the reduction of the particle size of the nanoparticles, the specific surface area increases, the number of surface atoms increases, and the surface atoms coordinate Unsaturation leads to a large number of dangling bonds and unsaturated bonds, which increases the chemical activity of nanoparticles, thereby improving the wettabili...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment differs from Embodiment 1 in that: the atomic percentages of Al element, Cu element and Ti element in the Al-based amorphous / nanocrystalline composite solder are 75:20:5 in sequence. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: this embodiment is different from specific embodiment one or two in that: the atomic percentages of Al element, Cu element and Ti element in the Al-based amorphous / nanocrystalline composite solder are 72:20:8 in sequence . Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com