Method for preparing high-purity high-activity magnesium hydroxide through calcium-containing magnesium hydroxide

A technology of magnesium hydroxide and high activity, applied in the direction of magnesium hydroxide, etc., can solve the problems of low purity and low efficiency, and achieve the effect of high purity, high efficiency and improved activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

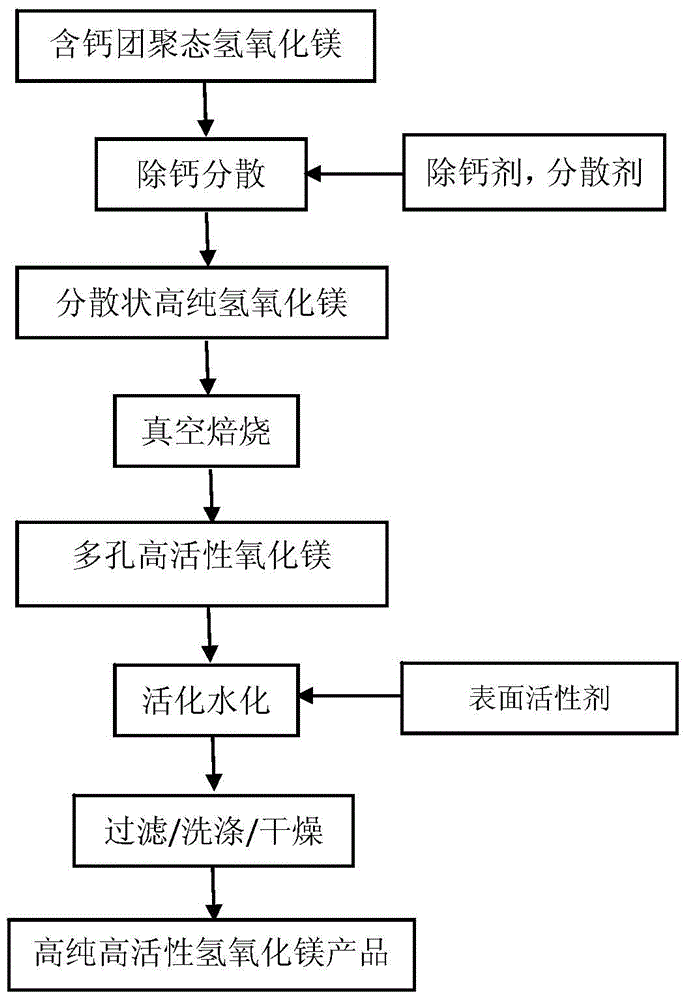

Method used

Image

Examples

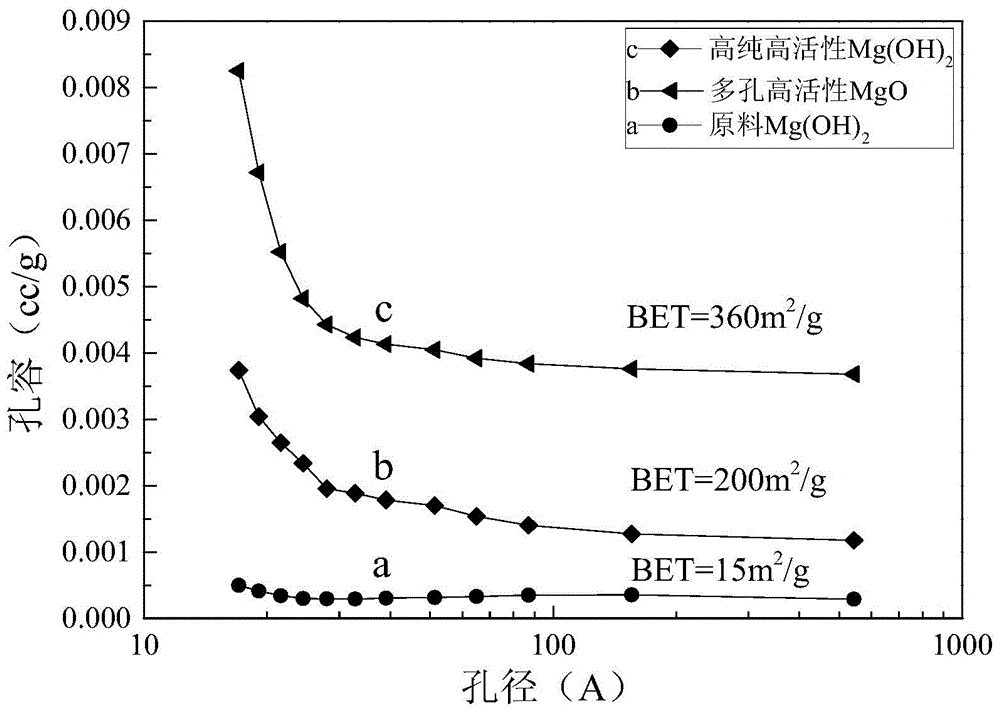

Embodiment 1

[0031] Take by weighing 100 grams of calcium-containing agglomerated magnesium hydroxide raw material (calcium content 10wt%, average primary particle diameter 0.1 micron, average agglomerated particle diameter 5 microns, specific surface area 40m 2 / g, magnesium hydroxide main content 85wt%,), add the aqueous solution that contains 0.01wt% tartaric acid, 20wt% sodium chloride, make solid containing 1wt% suspension, stir (800 rev / min) at 10 ℃ then and react 0.5 Hour, filter, wash, dry (110 ℃, 1 hour), obtain the dispersed high-purity magnesium hydroxide of main content 98.5wt%; Dispersed high-purity magnesium hydroxide is placed in vacuum furnace (vacuum degree 10 -3 Pa), raise the temperature to 300°C at 0.05°C / min in the air atmosphere, and roast at constant temperature for 1 hour to obtain a specific surface area of 800m 2 / g of porous active magnesia; above-mentioned magnesia is added to the aqueous solution containing 0.001wt% sodium stearate to make a suspension with a...

Embodiment 2

[0033] Take by weighing 100 grams of calcium-containing agglomerated magnesium hydroxide raw material (calcium content 0.01wt%, average primary particle diameter 4 microns, average aggregated particle diameter 50 microns, specific surface area 5m 2 / g, magnesium hydroxide main content 97wt%), add the aqueous solution that contains 20wt% ethylenediaminetetraacetic acid, 0.01wt% potassium chloride, 5wt% sodium hexametaphosphate, make solid containing 30wt% suspension, then in 100 ℃ stirring (50 revs / min) reaction 36 hours, filter, wash, dry (80 ℃, 6 hours), obtain the dispersed high-purity magnesium hydroxide of main content 98.8wt%; Dispersed high-purity magnesium hydroxide is placed in vacuum furnace (vacuum degree 10 4 Pa), heated up to 700°C at 30°C / min in a nitrogen atmosphere, and roasted at a constant temperature for 24 hours to obtain a specific surface area of 100m 2 / g of porous active magnesium oxide; adding the above magnesium oxide to an aqueous solution containi...

Embodiment 3

[0035] Take by weighing 100 grams of calcium-containing agglomerated magnesium hydroxide raw material (calcium content 5wt%, average primary particle diameter 2 microns, average agglomerated particle diameter 15 microns, specific surface area 35m 2 / g, magnesium hydroxide main content 92wt%), add the aqueous solution containing 10wt% sodium nitrilotriacetate, 2wt% tartaric acid, 0.5wt% magnesium chloride, make solid containing 20wt% suspension, then stir at 90 ℃ (450 rpm / min) reacted for 3 hours, filtered, washed, and dried (90°C, 2 hours), to obtain the dispersed high-purity magnesium hydroxide with a main content of 98.6wt%; the dispersed high-purity magnesium hydroxide was placed in a vacuum furnace (vacuum degree 10 -2 Pa), heated up to 500°C at 20°C / min in a nitrogen atmosphere, and roasted at a constant temperature for 14 hours to obtain a specific surface area of 300m 2 Porous activated magnesia per g; above-mentioned magnesia is added to the aqueous solution contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com