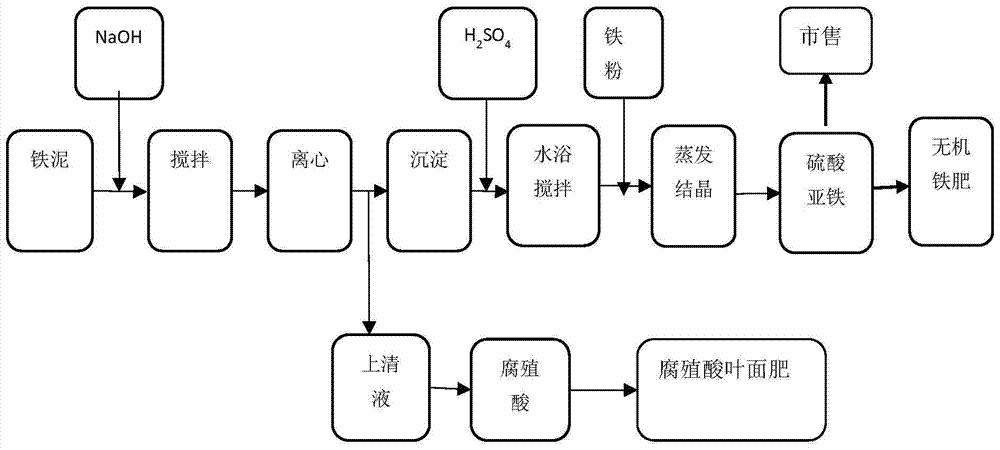

Method for extracting humic acid liquid fertilizer and inorganic iron fertilizer from Fenton's iron slime

A technology of humic acid and liquid fertilizer, applied in organic fertilizers, fertilization devices, fertilizer mixtures, etc., can solve problems such as difficulty in filtration, and achieve the effects of simple process operation, promotion of activity, and reduction of empty shell rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] The main indicators of Fenton iron slime in a paper mill are shown in the table below.

[0022] Table 1 Main indicators of sludge in a sewage treatment plant

[0023] sample

[0024] Table 2 Chemical composition of sludge

[0025] sample

[0026] Table 3 The remaining heavy metal content in the sludge (mg / g sludge dry weight)

[0027] sample

[0028] Place the sludge in a beaker, add 0.1mol / L NaOH (10L / kg sludge) to it, stir at a speed of 10 rpm for 6 hours and then centrifuge at a speed of 4000 rpm for 10 Minutes, collect the extract E1. Add 25% sulfuric acid (addition amount: 4L / kg sludge) to the precipitation, stir and extract at 10 rpm in a water bath at 70°C for 0.5 hours, collect the extract and record it as E2. Add reduced iron powder (0.6kg / kg) into the extract E2, and then obtain inorganic iron fertilizer after crystallization, cooling and drying. The organic humic acid foliar fertilizer can be prepared by concentrating the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com